Throw-beating type impact friction-wear test device

A wear test, impact friction technology, applied in the direction of testing wear resistance, etc., can solve the problem of a single test device, and achieve the effect of simple and convenient test operation, compact structure, and long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

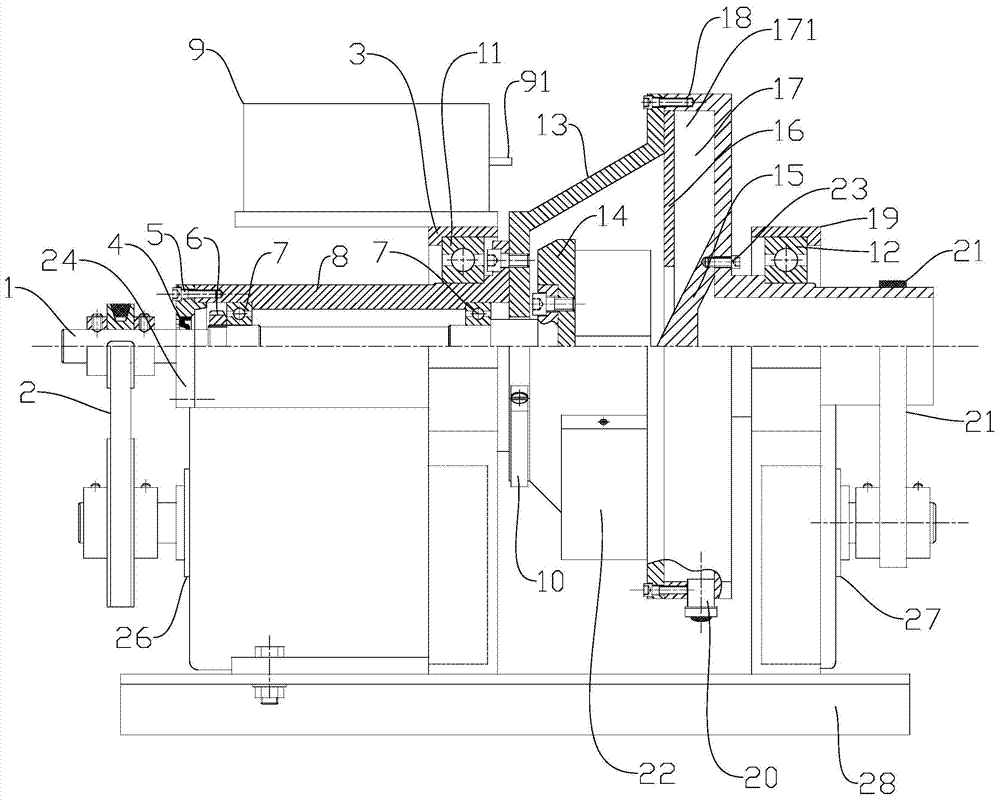

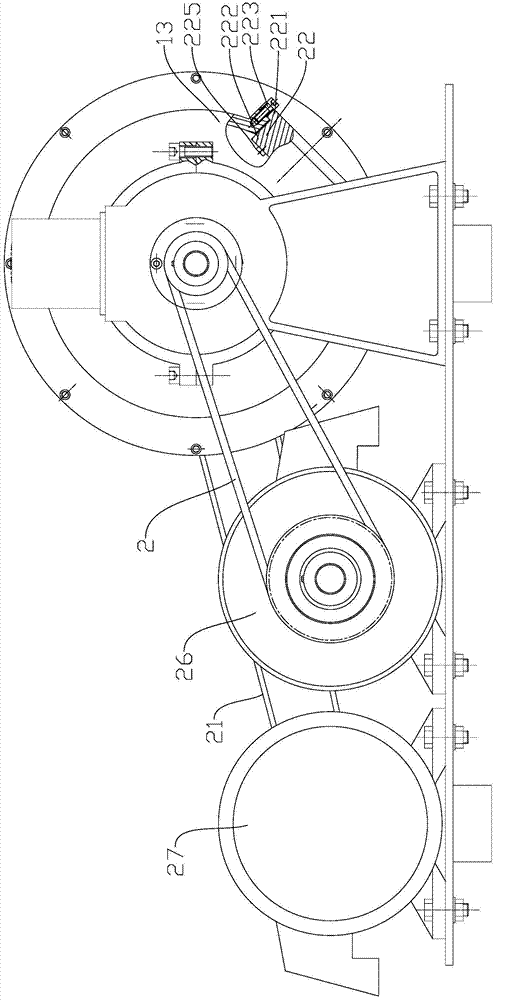

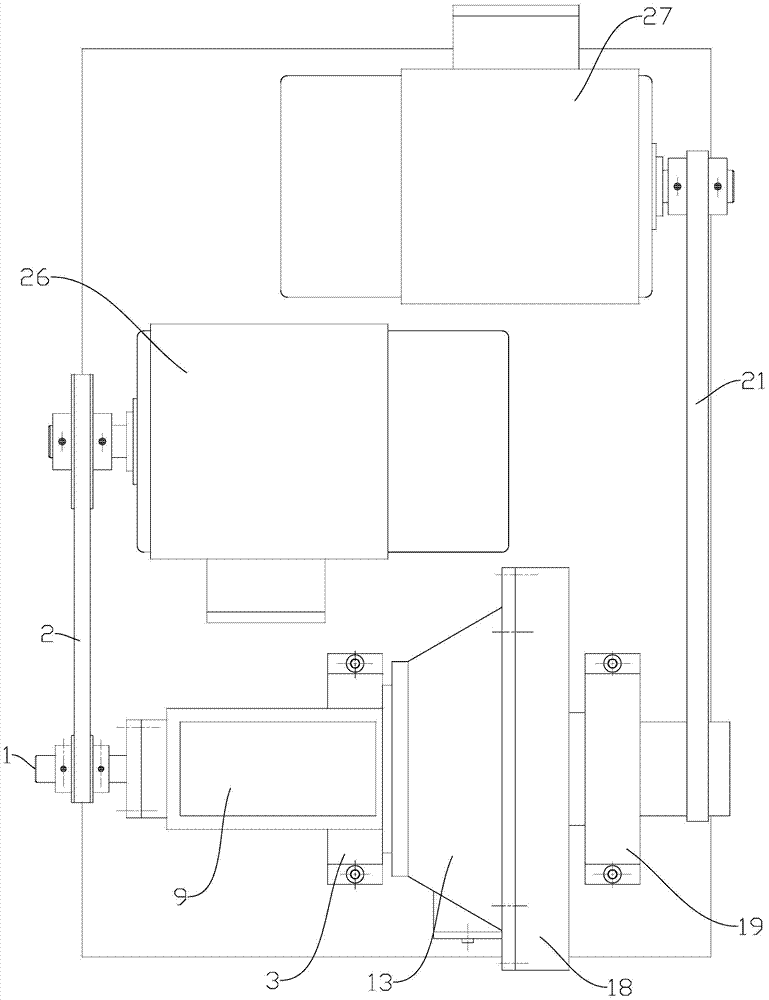

[0043] Such as figure 1 , 2 , 3, the throwing type impact friction and wear test device mainly includes a main shaft 1, a throwing head 14, a left casing 13, a right casing 18, a first motor 26, a second motor 27, a counter 9, and a guide groove 16 , Guide block 15, left bracket 3, right bracket 19.

[0044] The left end of the main shaft 1 is driven by a first motor 26 through a belt drive; the belt drive here is a V-belt drive 2 . The right end of main shaft 1 is relatively fixedly installed throwing head 14.

[0045] Throwing head 14 comprises connecting portion 141 and protruding portion 142, as Figure 4 , 5 As shown in , 6, the connecting part 141 is connected to the right end of the main shaft 1, and there are two protruding parts 142, and the two protruding parts 142 are arc-shaped plates that rotate along the axis of the main shaft; The blades in the tangential direction are fixed on the first protruding part 142; the throwing head 14 is located in the left housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com