Preparation method of magnetorheological fluid applied to high-power occasion

A magnetorheological fluid, high-power technology, applied in the direction of magnetic fluids, etc., can solve the problem of rapid increase in working temperature, and achieve the effect of being conducive to the magnetorheological effect and good friction reduction ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

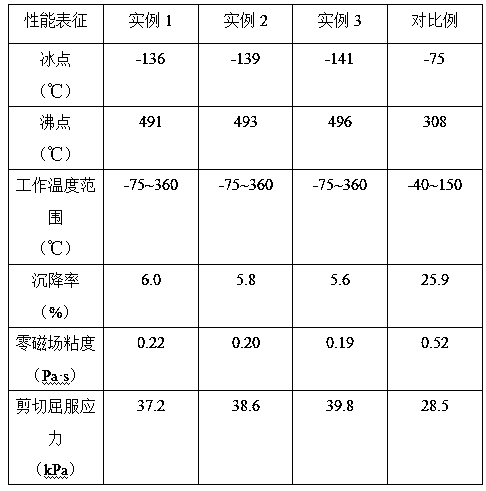

Examples

Embodiment Construction

[0036] In terms of parts by weight, weigh 10-15 parts of hydroxyl iron powder, 5-10 parts of phosphoric acid with a mass concentration of 20%, and 20-30 parts of absolute ethanol. Stir at 300-400r / min for 15-20min to obtain phosphating solution, add hydroxyl iron powder to the phosphating solution, stir at 300-400r / min for 30-40min at room temperature, filter with suction, take filter cake, wash with acetone for 3-5 Once again, put it at 50~60℃ and dry for 1~1.5h to get phosphating hydroxy iron powder, and weigh 3~5 parts of octyltriethoxysilane and 1~3 parts by weight respectively 10% acetic acid, 10~20 parts of deionized water, 80~90 parts of absolute ethanol, 8~10 parts of carbonyl phosphide iron powder, add octyltriethoxysilane, acetic acid, deionized water to anhydrous ethyl alcohol , stir at 160~180r / min for 20~30min at room temperature to obtain octyltriethoxysilane modified liquid, add carbonyl iron phosphide powder into octyltriethoxysilane modified liquid, Stir magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com