Optical detection system for defects of billet and detection method thereof

A defect optics and detection system technology, applied in the defect detection system and its detection field, can solve the problems of insufficient system inspection coverage and lack of detection ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

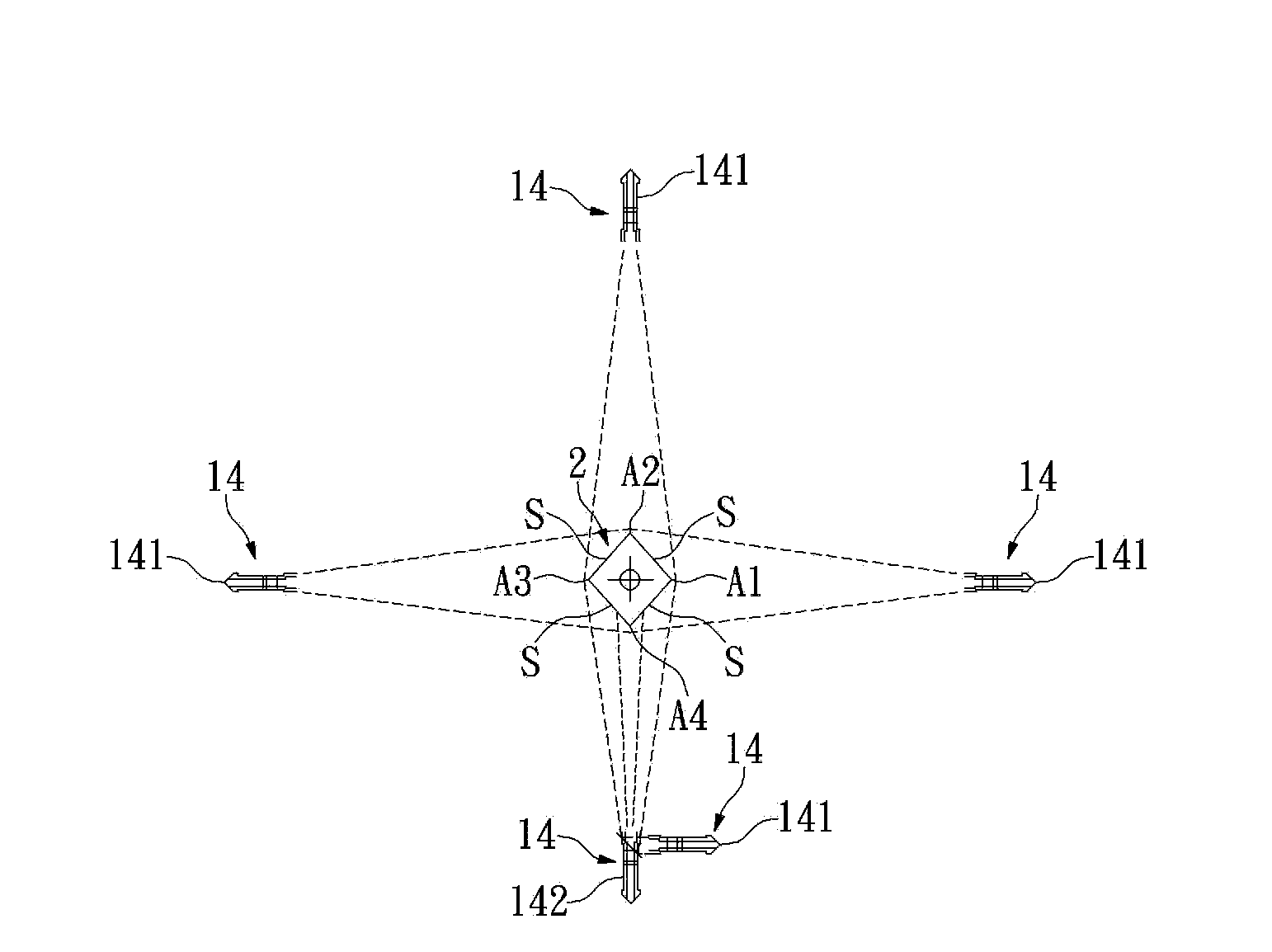

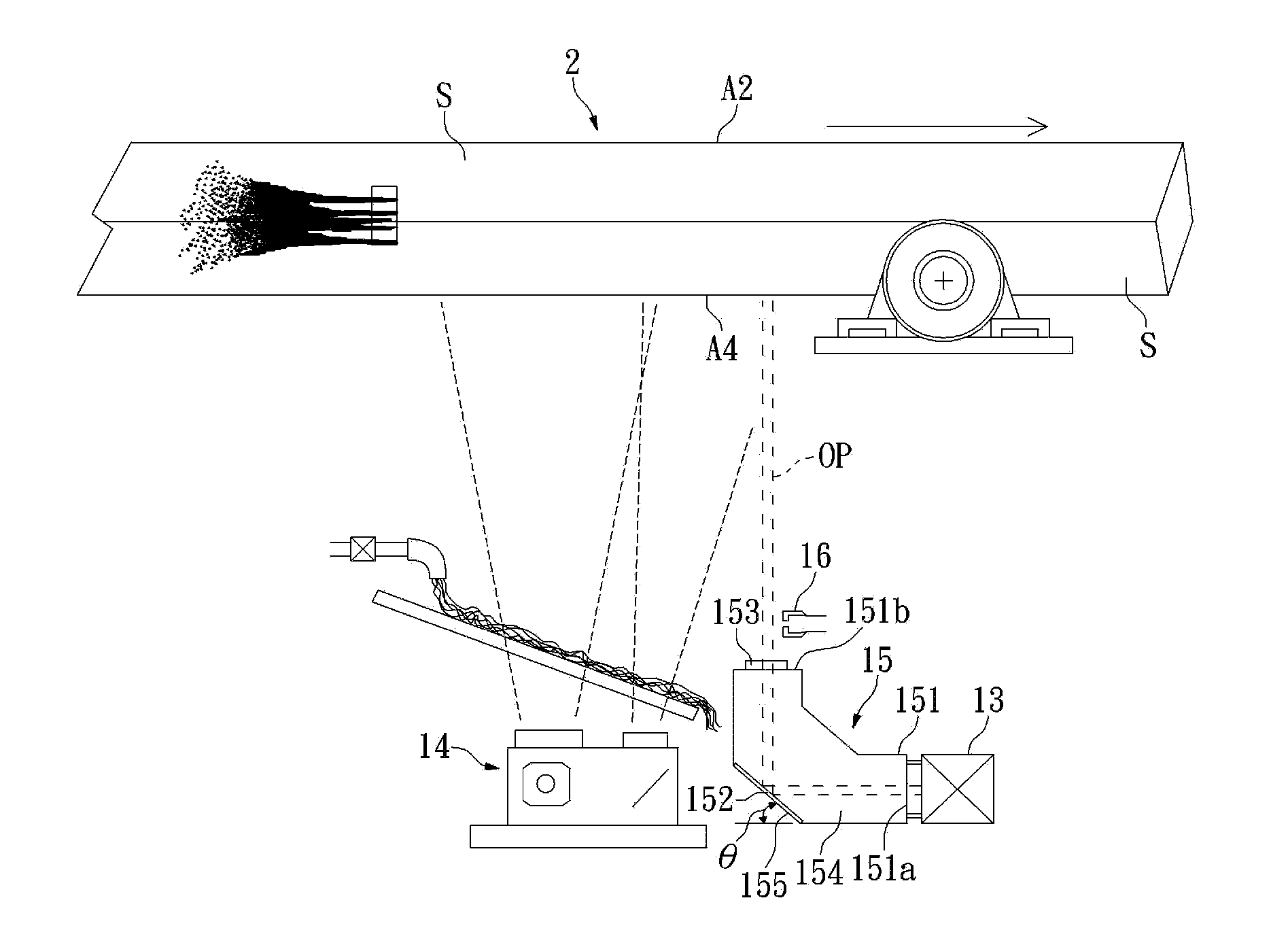

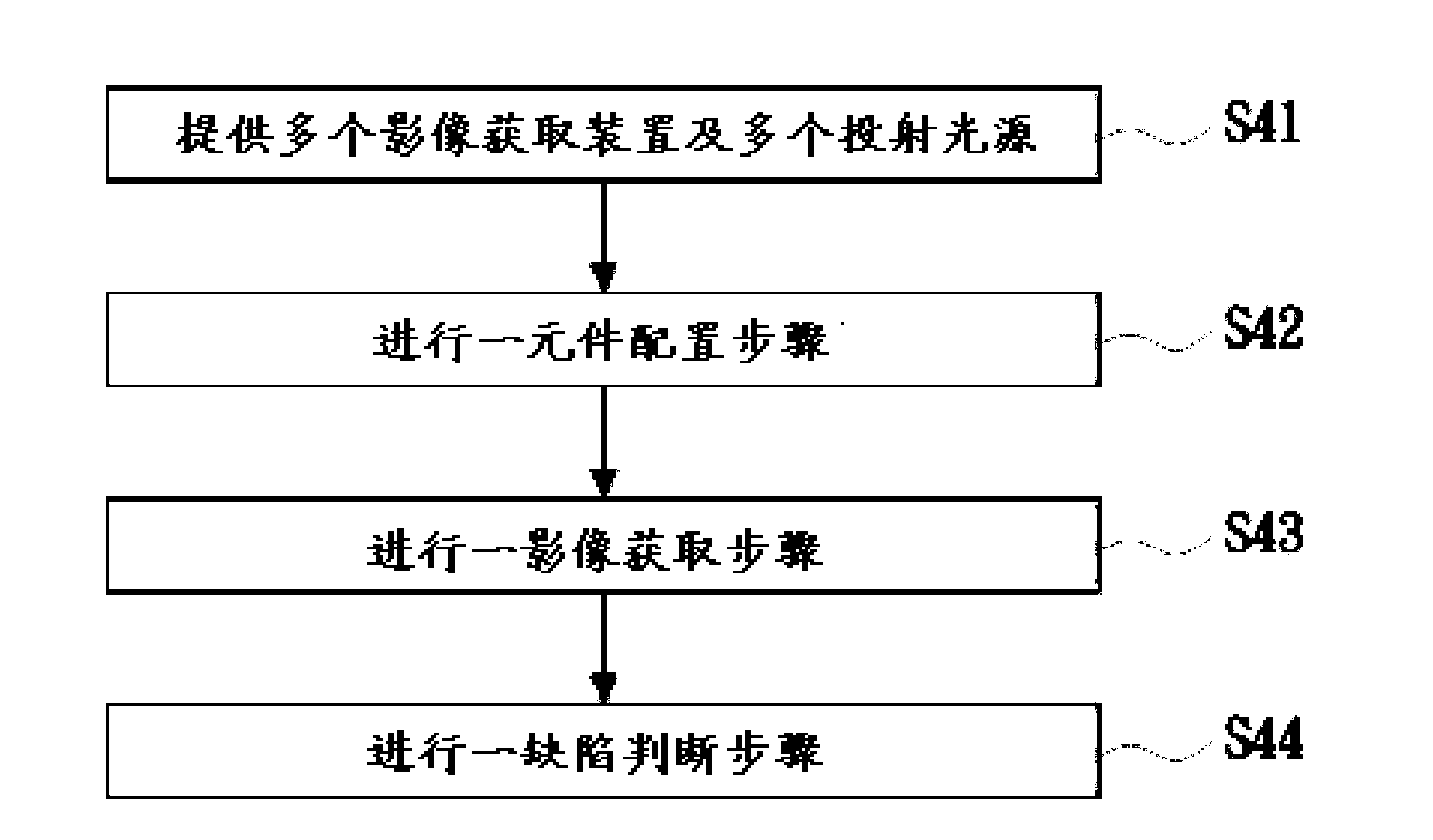

[0015] figure 1 A schematic diagram showing the structure of the steel billet defect optical detection system of the present invention; figure 2 A schematic configuration diagram of the projection light source of the present invention is shown. Please refer to figure 1 and figure 2 , the steel blank defect optical detection system of the present invention includes: a plurality of first matrix image acquisition devices 11, a plurality of second matrix image acquisition devices 12, a line image acquisition device 13, a plurality of projection light sources 14 and an image data Processing device (not shown in the figure).

[0016] The plurality of first matrix image acquisition devices 11 respectively face four surfaces S of a steel billet 2 to acquire images of each surface S respectively. The steel billet 2 can be selected from one of the following: diamond-shaped steel billets, square steel billets and rectangular steel billets. In this embodiment, the steel billet 2 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com