Method for controlling assembly temperature in photovoltaic assembly temperature coefficient test

A photovoltaic module and temperature coefficient technology, applied in the field of photovoltaics, can solve problems such as inaccurate test results and temperature differences, achieve accurate stability and reduce temperature differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

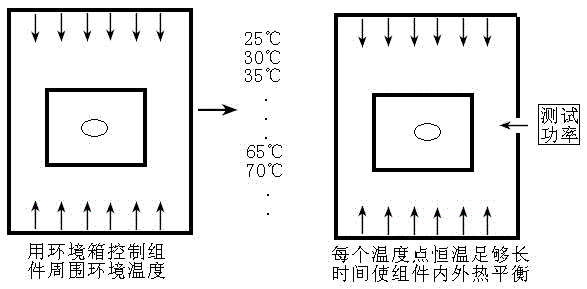

[0019] As shown in the accompanying drawings, a method for controlling the temperature of a photovoltaic module during a temperature coefficient test of a photovoltaic module according to the present invention, the specific steps of the manufacturing method are as follows:

[0020] (a) Place the photovoltaic module in the environmental test chamber, and the size of the test chamber is 1.8m*1.5m*2.0m;

[0021] (b) Heat the temperature inside the environmental test chamber to 25°C with an electric heater;

[0022] (c) The photovoltaic module is stabilized at the set ambient temperature for 50 minutes to reach thermal equilibrium;

[0023] (d) By using the photovoltaic module electrical performance test system to test the power of the photovoltaic module under the condition of 25°C, the power value is obtained;

[0024] (e) Repeat steps b-d for the first time, complete the power test of the photovoltaic module under the condition of heating the temperature in the environmental t...

Embodiment 2

[0029] As shown in the accompanying drawings, a method for controlling the temperature of a photovoltaic module during a temperature coefficient test of a photovoltaic module according to the present invention, the specific steps of the manufacturing method are as follows:

[0030] (a) Place the photovoltaic module in the environmental test chamber, and the size of the test chamber is 1.8m*1.5m*2.0m;

[0031] (b) Heat the temperature inside the environmental test chamber to 25°C through the light heater;

[0032] (c) The photovoltaic module is stable at the set ambient temperature for 60 minutes to reach thermal equilibrium;

[0033] (d) By using the photovoltaic module electrical performance test system to complete the power test of the photovoltaic module under the condition of 25°C, the power value is obtained;

[0034] (e) Repeat steps b-d for the first time, and complete the power test of the photovoltaic module under the condition of heating the temperature in the envir...

Embodiment 3

[0039] As shown in the accompanying drawings, a method for controlling the temperature of a photovoltaic module during a temperature coefficient test of a photovoltaic module according to the present invention, the specific steps of the manufacturing method are as follows:

[0040] (a) Place the photovoltaic module in the environmental test chamber, and the size of the test chamber is 1.8m*1.5m*2.0m;

[0041] (b) Heat the temperature inside the environmental test chamber to 25°C through an electric heater or a light heater;

[0042] (c) The photovoltaic module is stable at the set ambient temperature for 60 minutes to reach thermal equilibrium;

[0043] (d) By using the photovoltaic module electrical performance test system to test the power of the photovoltaic module under the condition of 25°C, the power value is obtained;

[0044] (e) Repeat steps b-d for the first time, and complete the power test of the photovoltaic module under the condition of heating the temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com