Bottle mouth defect detection method

A defect detection and normal detection technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of poor stability, low precision, slow speed, etc., and achieve stable performance, high precision, and convenient debugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

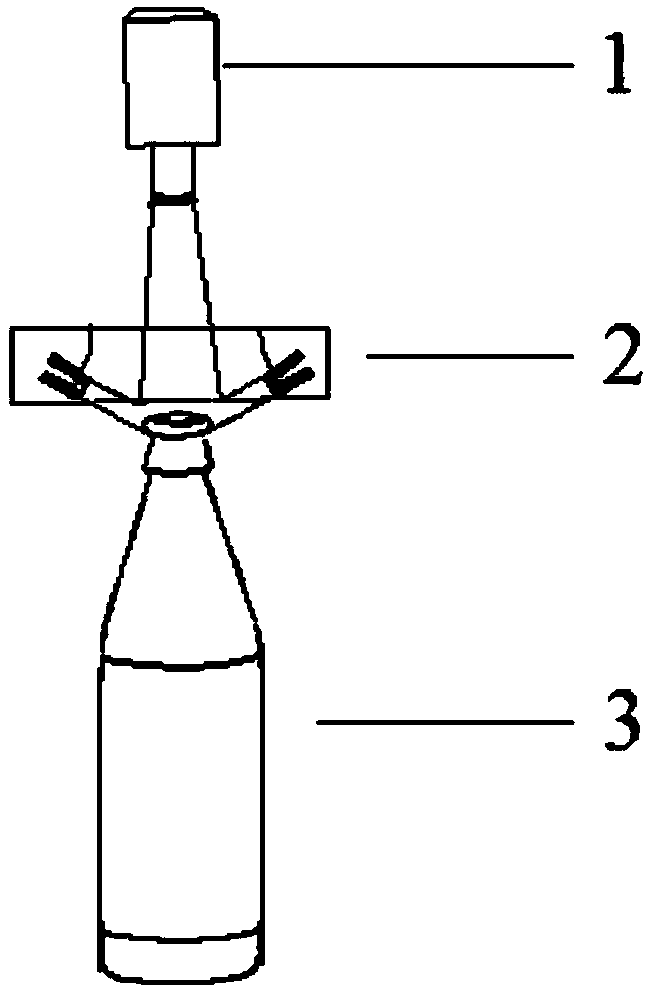

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

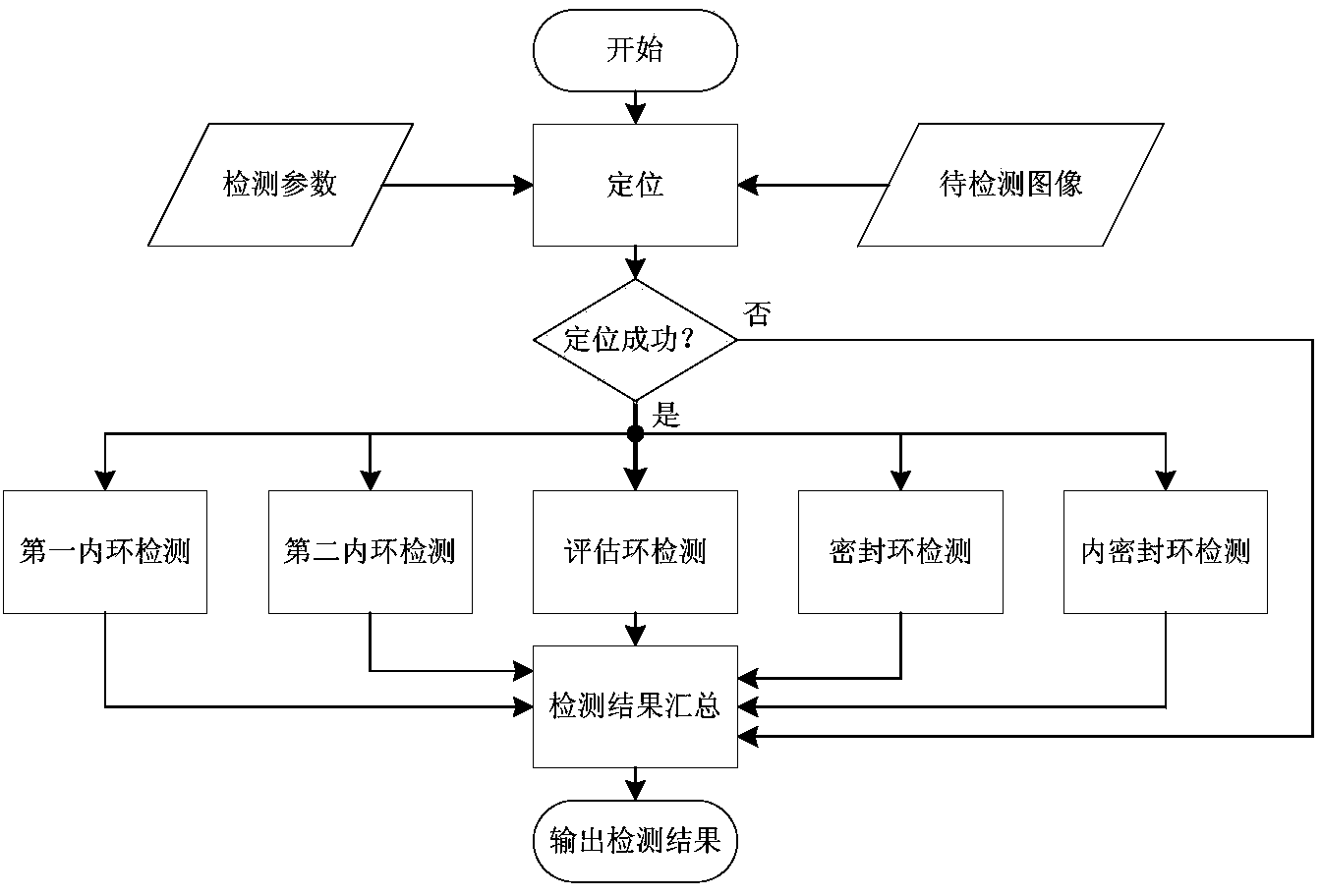

[0021] The invention provides a method for detecting a bottle mouth defect, comprising:

[0022] S1. Divide the detection area of the bottle mouth, and use the parallel computer mechanism to simultaneously detect the first inner ring, the second inner ring, the evaluation ring, the sealing ring and the inner sealing ring;

[0023] S2. Summarize the test results, and finally output the comprehensive test result for the bottle mouth. If there is no less than one test item with abnormal output, the test result is abnormal, otherwise the test result is normal.

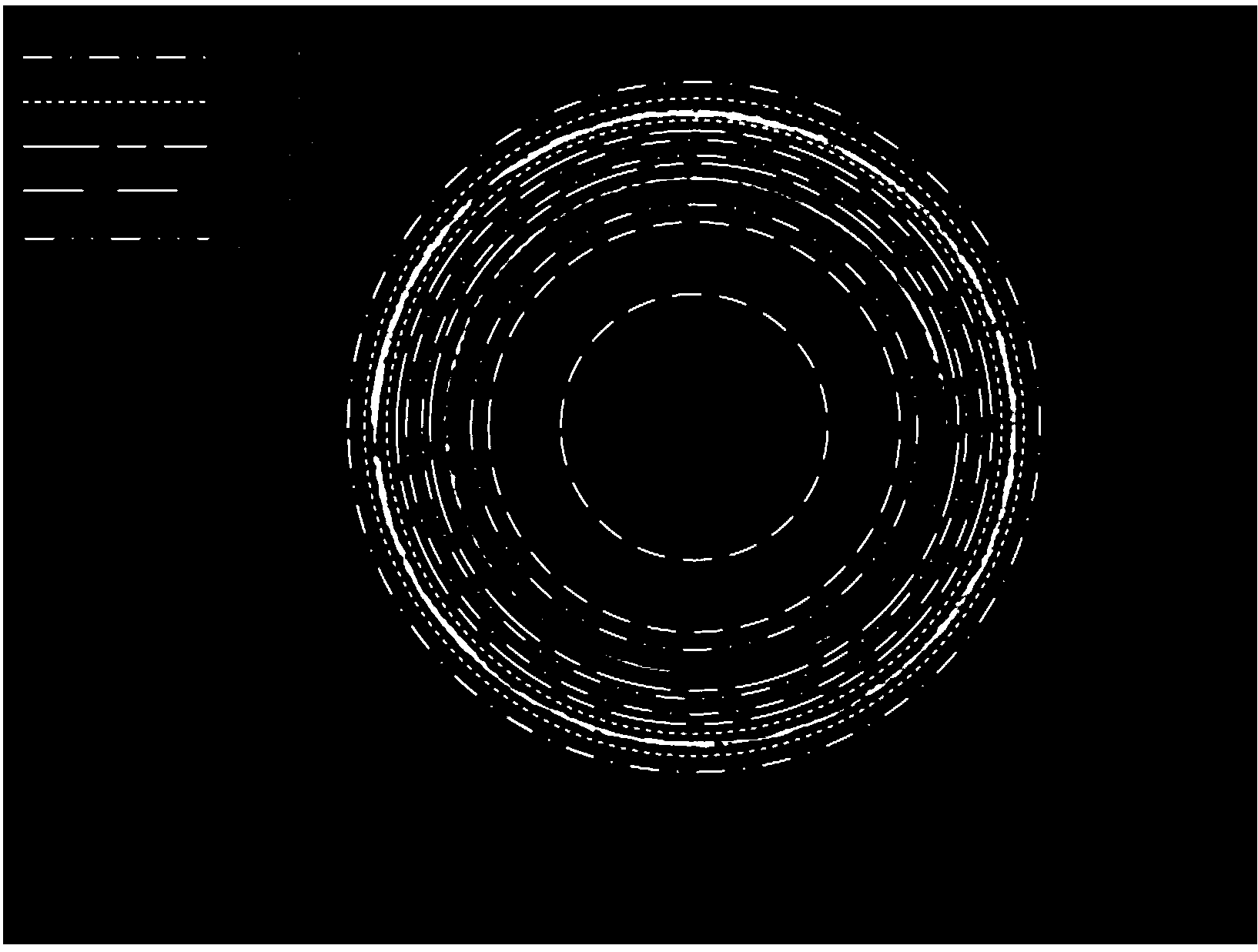

[0024] Wherein, in the step S1, the first inner ring, the second inner ring, the evaluation ring, the sealing rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com