A pressure-resistant detection device for safety tools

A technology for safety tools and withstand voltage testing, which is applied in the direction of measuring devices, instruments, and measuring electricity, and can solve problems such as low detection efficiency, complicated installation of suspension insulators, and uneven short grounding rods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

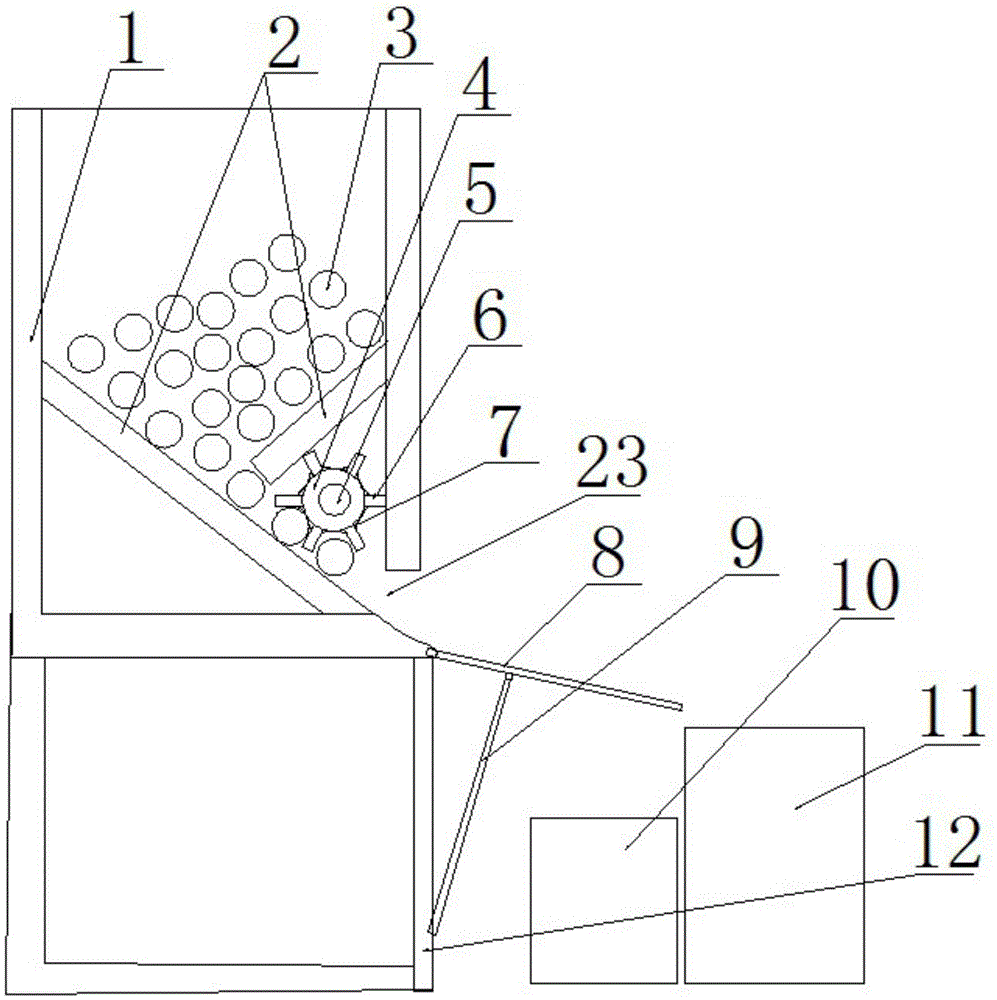

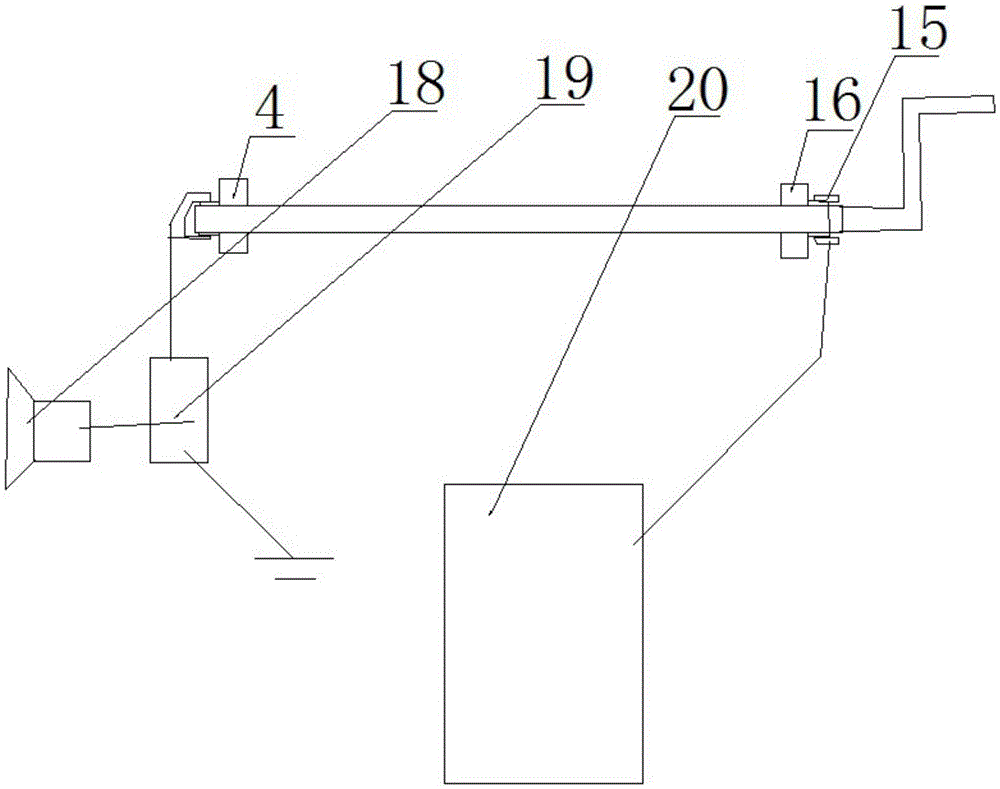

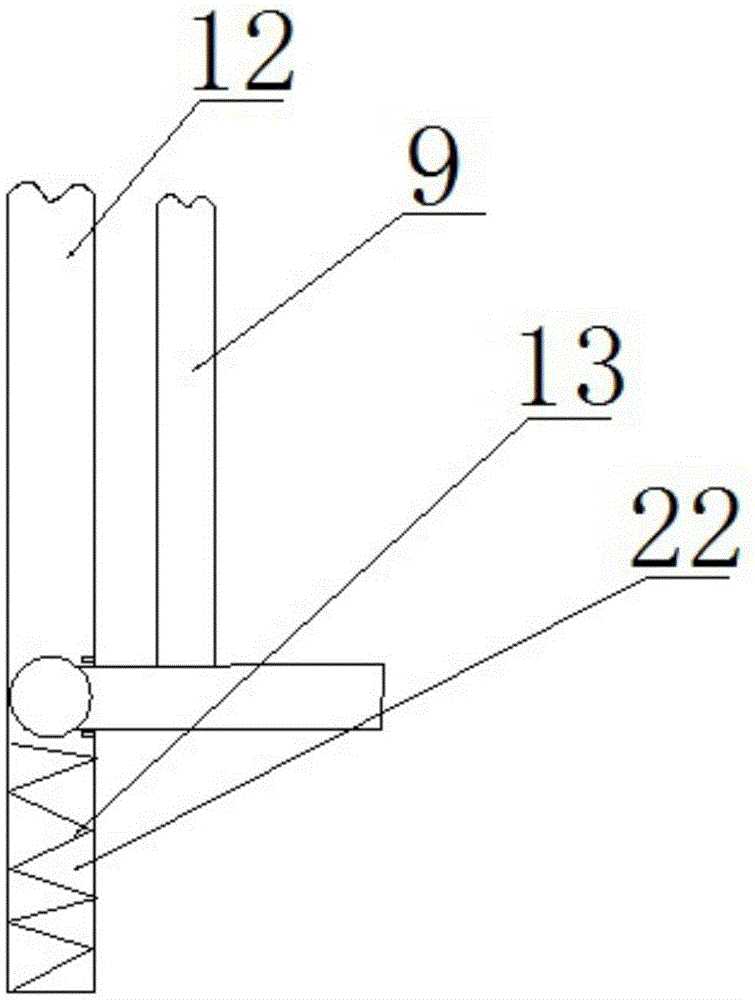

[0020] Example 1: Such as figure 1 , 2 , 3, 4, and 5, a pressure detection device for safety tools, including a box body 1, the box body 1 is provided with a deflector 2, the deflector 2 is in the shape of an inverted figure, and the reverse flow effect is good; below the box 1 An appliance outlet 23 is provided. A rotating shaft 5 with a rotating handle is arranged at the appliance outlet 23. One end of the rotating shaft 5 is sleeved with a grounding roller 4, and the other end is sleeved with a high-pressure roller 16, on the ground roller 4 and the high-pressure roller 16 A dial plate 6 is set, the dial plate is evenly spaced on the dial roller, the distance between the two dial plates 6 is just an insulating rod, and the ground roller and the high-voltage roller are both provided with elastic conductive members 7 , The box body 1, the flow guide 2, the rotating shaft 5 and the shift plate 6 are all made of insulating materials.

Embodiment 2

[0021] Example 2: Such as figure 1 , 2 , 3, 4, and 5, a pressure detection device for safety tools, including a box body 1, the box body 1 is provided with a deflector 2, the deflector 2 is in the shape of an inverted figure, and the reverse flow effect is good; below the box 1 An appliance outlet 23 is provided. A rotating shaft 5 with a rotating handle is arranged at the appliance outlet 23. One end of the rotating shaft 5 is sleeved with a grounding roller 4, and the other end is sleeved with a high-pressure roller 16, on the ground roller 4 and the high-pressure roller 16 A dial plate 6 is set, the dial plate is evenly spaced on the dial roller, the distance between the two dial plates 6 is just an insulating rod, and the ground roller and the high-voltage roller are both provided with elastic conductive members 7 , The box body 1, the flow guide 2, the rotating shaft 5 and the shift plate 6 are all made of insulating materials. The appliance outlet 23 is provided with a re...

Embodiment 3

[0022] Example 3: Such as figure 1 , 2 , 3, 4, and 5, a pressure detection device for safety tools, including a box body 1, the box body 1 is provided with a deflector 2, the deflector 2 is in the shape of an inverted figure, and the reverse flow effect is good; below the box 1 An appliance outlet 23 is provided. A rotating shaft 5 with a rotating handle is arranged at the appliance outlet 23. One end of the rotating shaft 5 is sleeved with a grounding roller 4, and the other end is sleeved with a high-pressure roller 16, on the ground roller 4 and the high-pressure roller 16 A dial plate 6 is set, the dial plate is evenly spaced on the dial roller, the distance between the two dial plates 6 is just an insulating rod, and the ground roller and the high-voltage roller are both provided with elastic conductive members 7 , The box body 1, the flow guide 2, the rotating shaft 5 and the shift plate 6 are all made of insulating materials. The appliance outlet 23 is provided with a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com