Position closed-loop system-based minimum phase difference tracking method

A closed-loop system and subtraction technology, applied in the direction of control using feedback, can solve problems such as insufficient performance of high-precision servo systems, and achieve the effect of obvious low-speed characteristics, improved system performance, and reduced tracking amplitude.

Inactive Publication Date: 2014-01-22

BEIHANG UNIV

View PDF3 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This classic control method is not enough to meet the performance requirements of high-precision servo systems, and the use of compound control methods has become the development trend of today's control systems

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

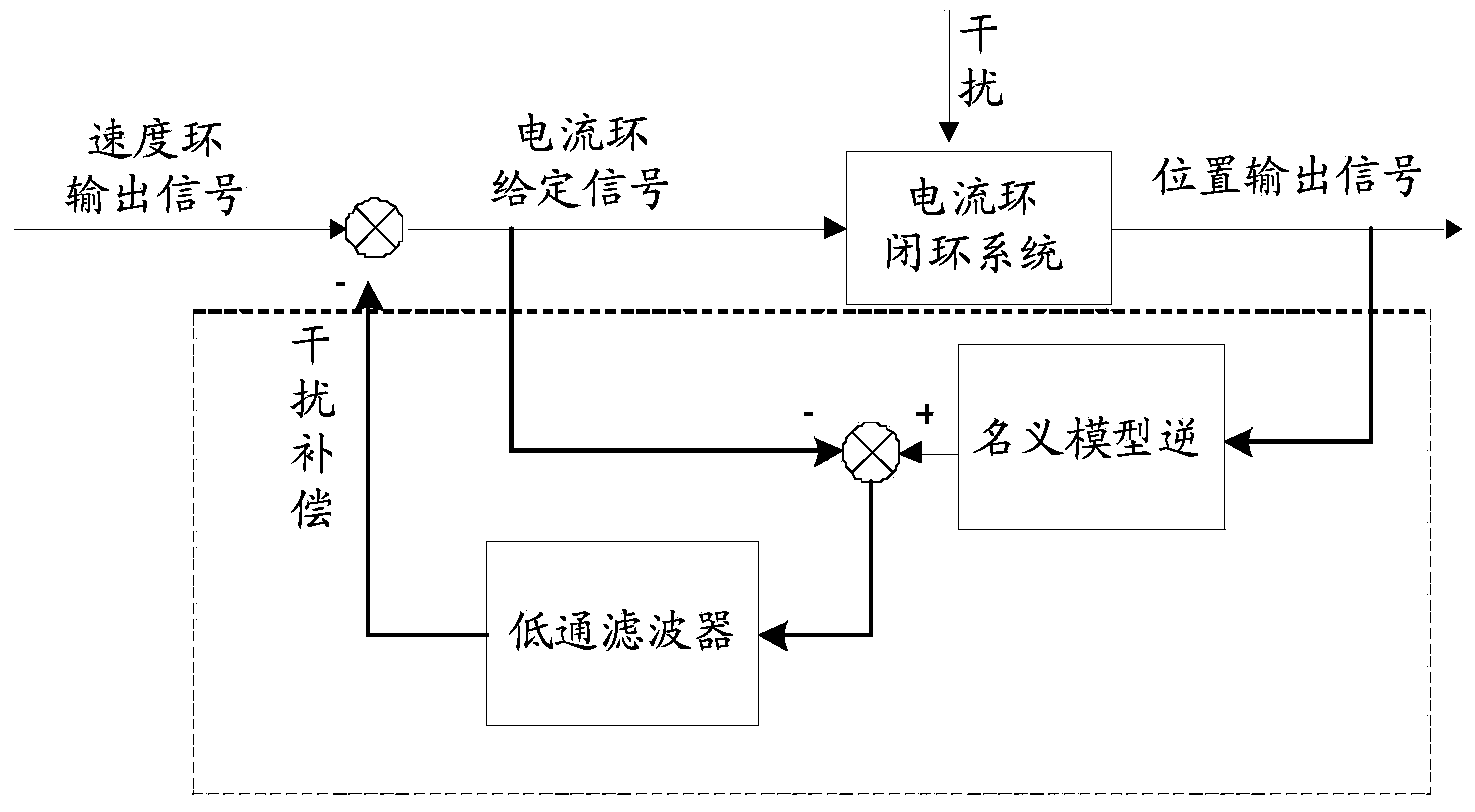

[0095] In an example, the nominal model identification results are as follows Figure 6 Shown, G n (s) Each coefficient is k=50, a 0 =10,a 1 =20,b 0=5. Each coefficient of the low-pass filter Q(s) is N=3, M=1, τ=0.02. The system design bandwidth is 0.5°, 3Hz.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

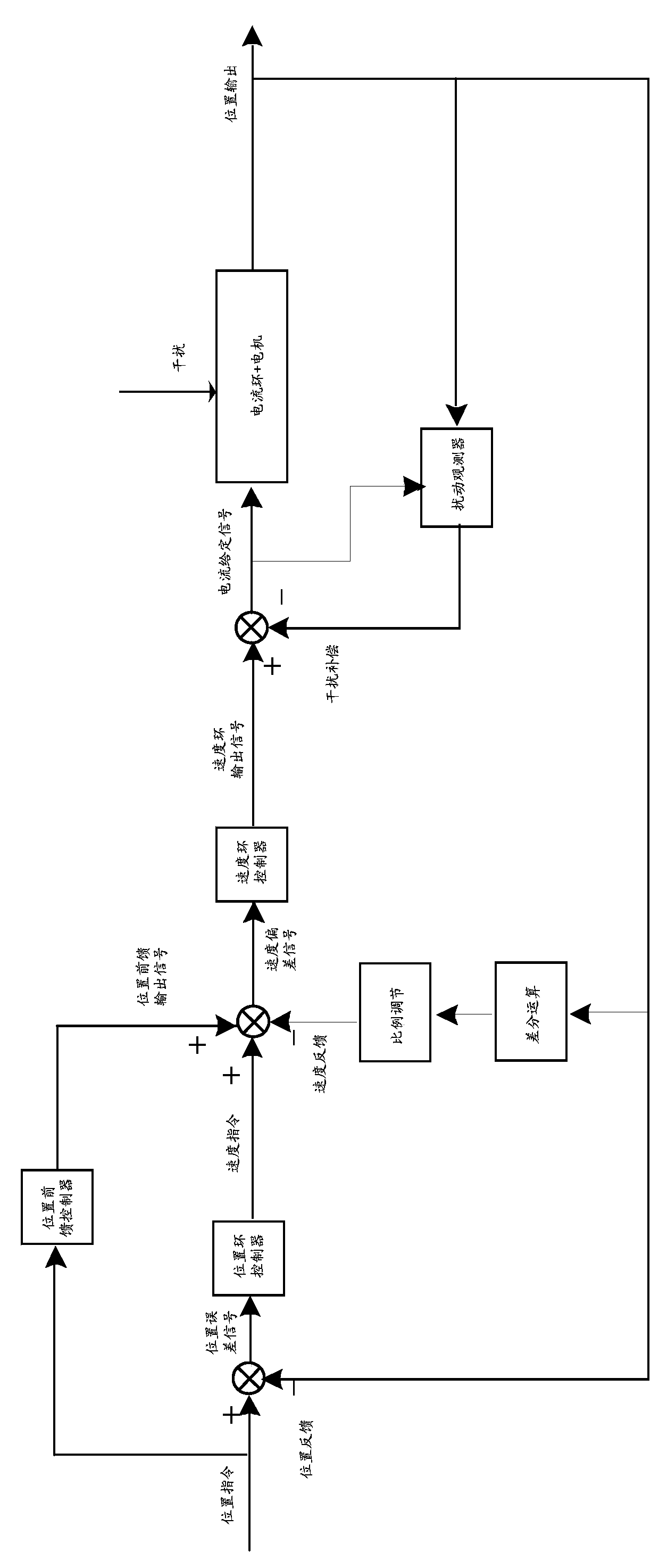

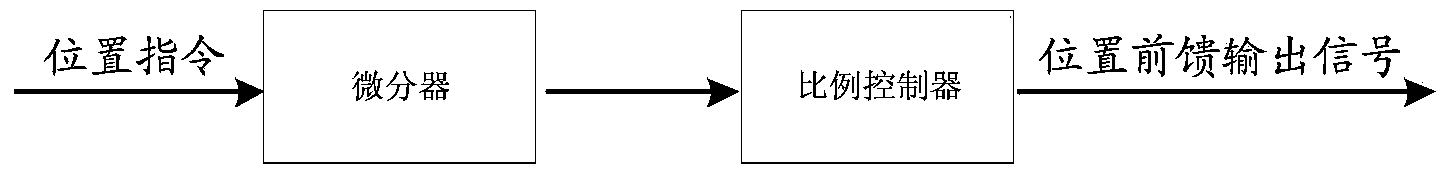

The invention discloses a novel control method, and aims to improve the tracking accuracy of a servo system. A current loop disturbance observer is constructed to effectively suppress the nonlinear disturbance of the system; a position differentiation method is used for constructing a speed closed loop on the basis of no speed measurement components to improve the rigidity (damping) of the system; a position instruction differentiation method is used for realizing first-order feed-forward and controlling the phase shift of the system; parameters of a position and speed controller are regulated to control a tracking amplitude difference; within a system index bandwidth range, double-one tracking indexes of an absolute value of a signal tracking amplitude difference of lower than 1 percent and phase lag of less than 1 degree can be achieved; particularly remarkable low-speed characteristics are achieved, and 0.00001-degree 0.024Hz distortion-free dynamic ultra-small signal tracking can be realized. The method has the characteristics of high control accuracy, wide application range, easiness for engineering practices and the like.

Description

technical field [0001] The invention relates to a servo system applied to a speed-measuring element and its minimum amplitude phase difference tracking method, which constructs a speed closed loop and increases the rigidity (damping) of the system. Background technique [0002] In recent years, with my country's outstanding achievements in aerospace, weapons development and other fields, as well as the rapid development of other industrial fields, high-precision servo systems have played a pivotal role. "High response, high precision, and ultra-low speed" are the core key elements in the development of high-precision servo systems, among which "high response" represents the ability of the servo system to track high-frequency signals; "high precision" reflects the ability of the system to track command signals Accuracy; "ultra-low speed" reflects the low-speed stability of the system. [0003] Factors affecting the performance of high-precision servo systems include many non...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G05D3/12

Inventor 扈宏杰张超

Owner BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com