Dual-heating laminated board

A double heating and laminated board technology, applied in the direction of ohmic resistance heating, electric heating devices, electrical components, etc., can solve the problems of fast heating wire rise speed, maximum temperature fluctuation, uneven heat transfer, etc., to improve work efficiency and meet the maximum High temperature requirement, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

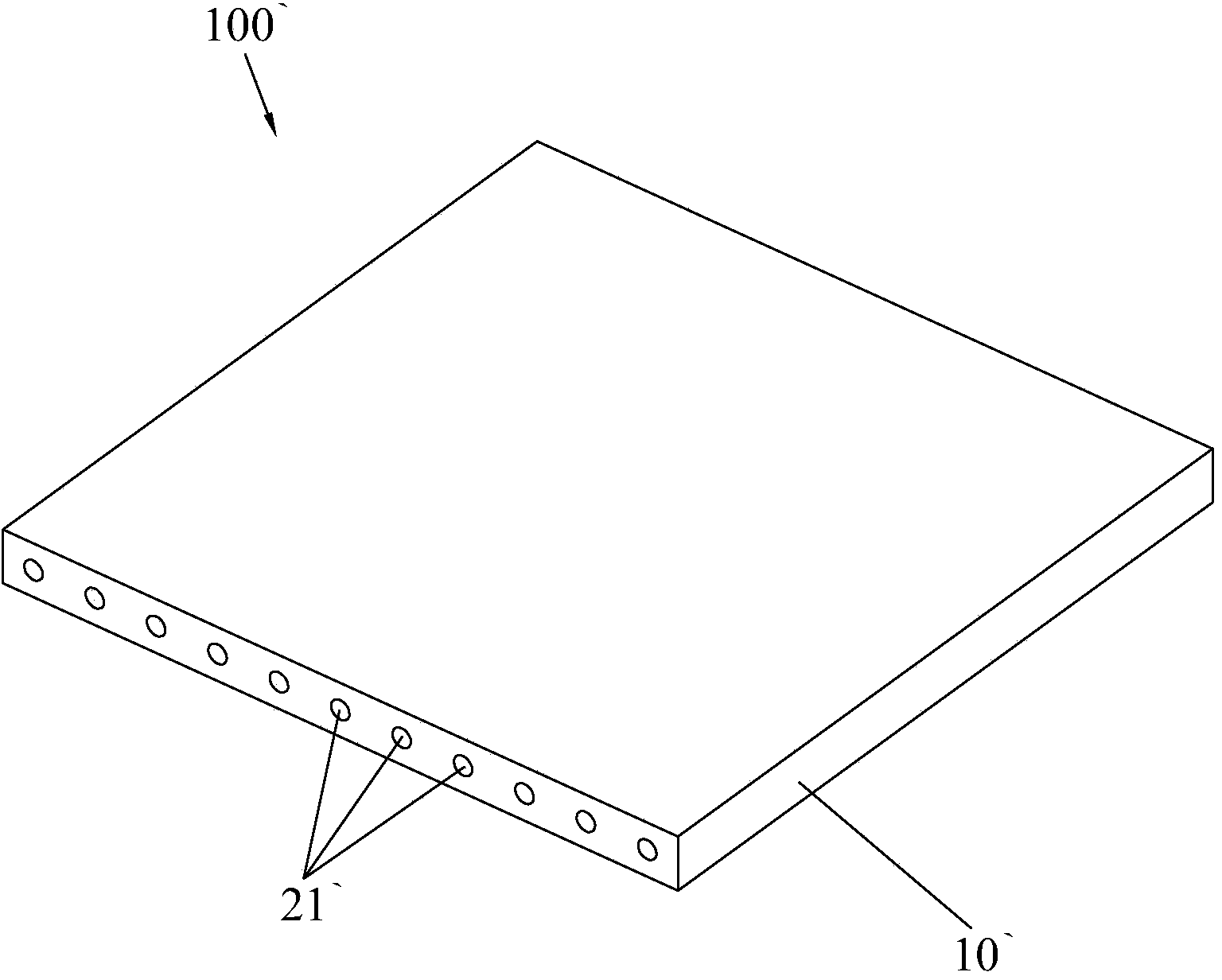

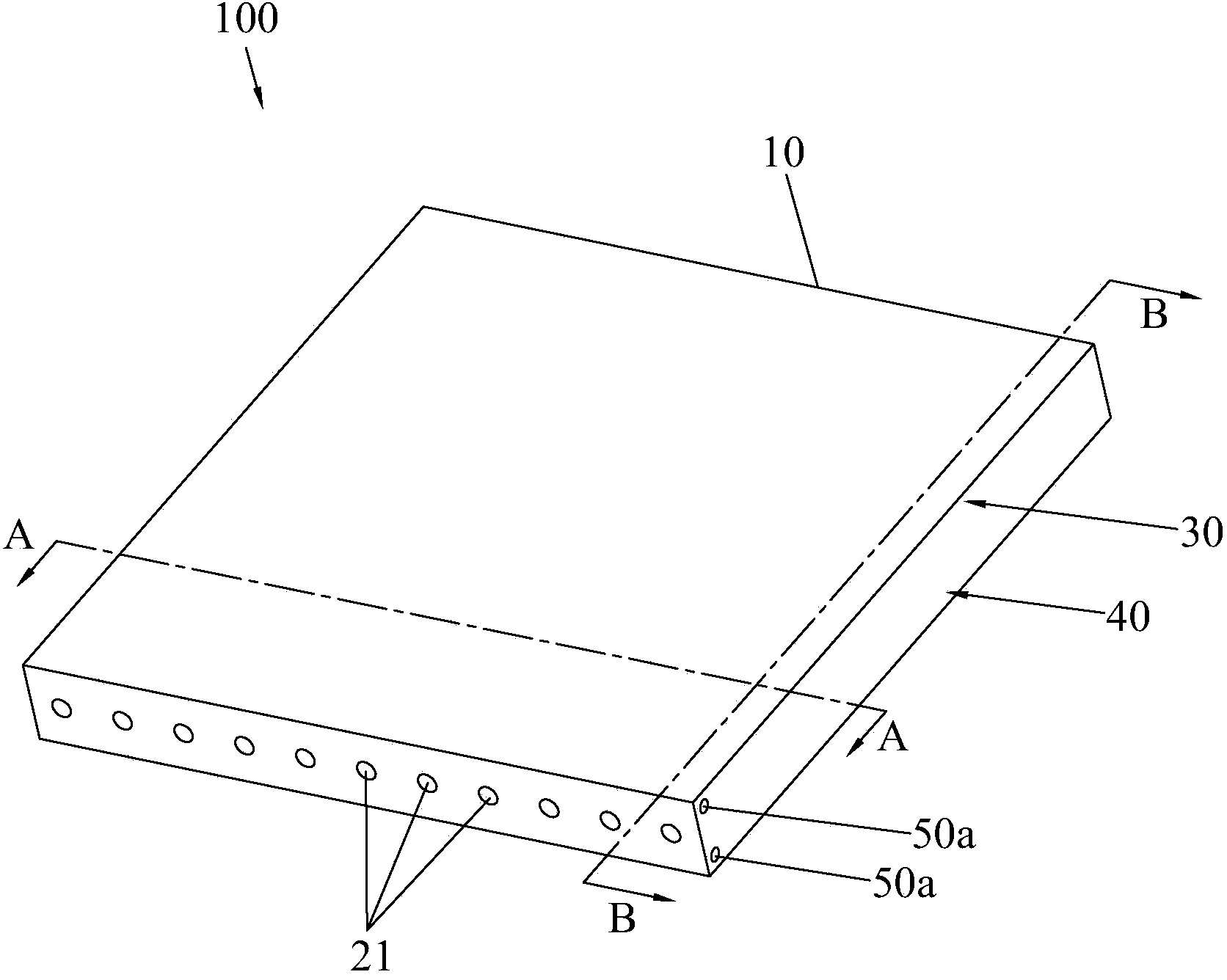

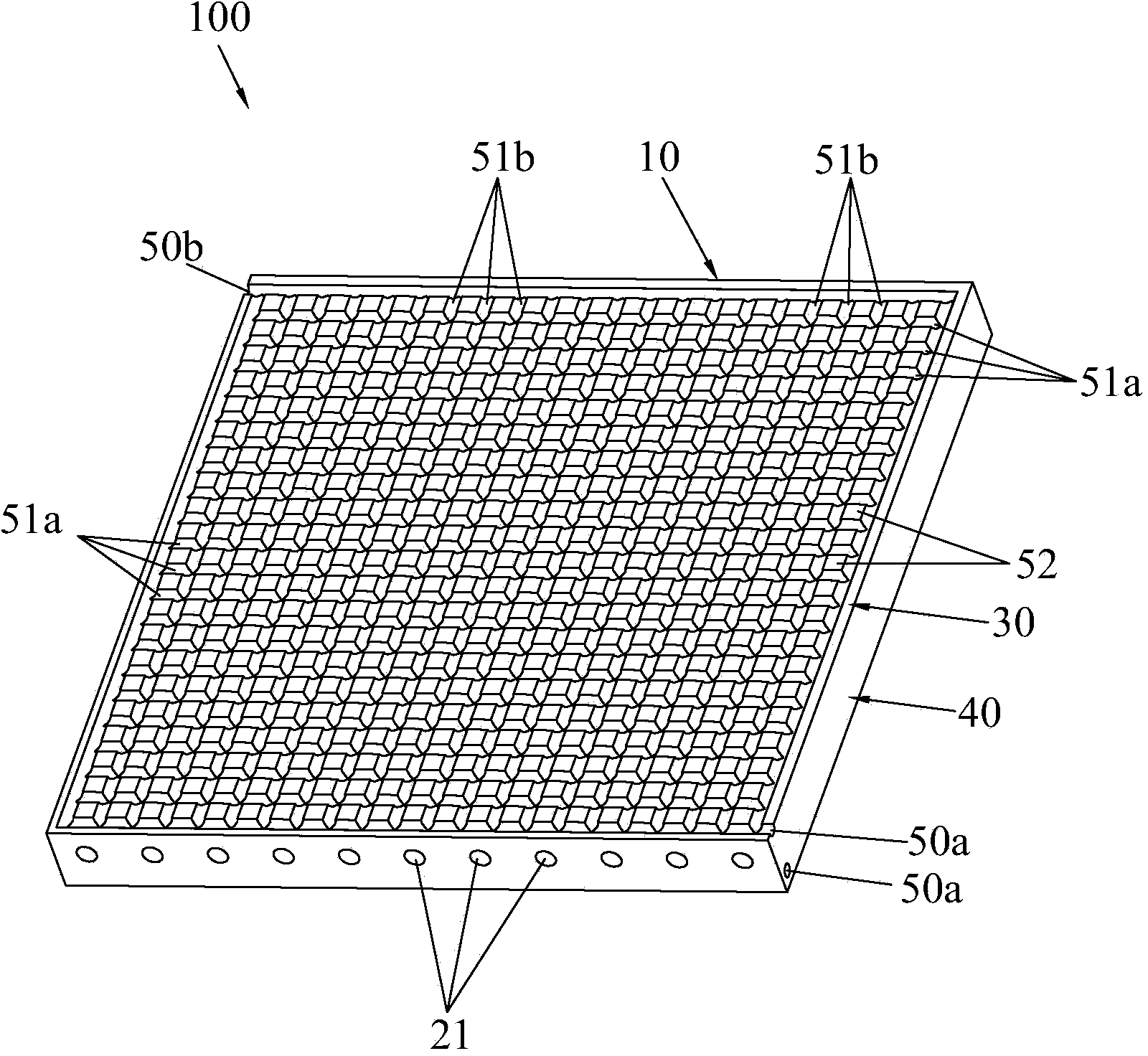

[0021] Such as Figure 2-Figure 6 As shown, the dual heating laminate 100 of the present invention includes a board body 10 and heating wires (not shown in the figure), the heating wires are uniformly arranged in the board body and form an electric heating layer 20, specifically, the The central position of the plate body 10 is provided with a number of parallel receiving holes 21 at equal intervals, and the heating wires are correspondingly installed in the receiving holes 21. The upper end 30 and the lower end 40 of the plate body 10 are provided with a number of equally spaced and staggered fluid channels. 51, interlaced fluid channels 51 form a grid-like fluid heating layer 50; The fluid heating layer 50 at the lower end 40 is symmetrically located on both sides of the electric heating layer 20 . Continue to combine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com