Use of propylene glycol to control the degree of heat -induced foam generation a food system

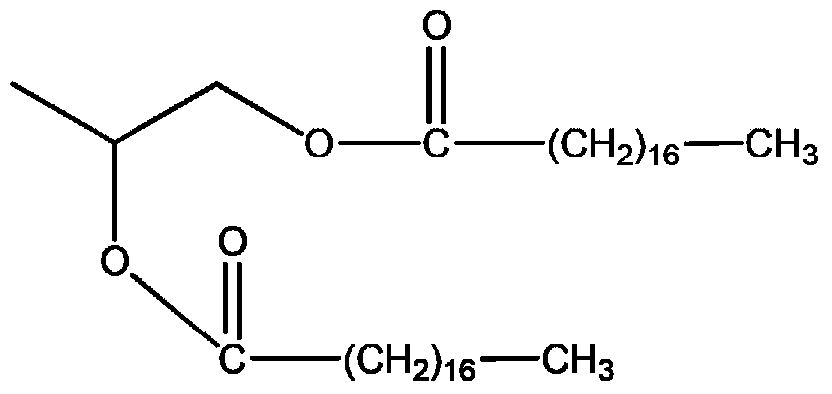

A thermally induced foaming, propylene glycol monoester technology, applied in food preservation, food preparation, food ingredients as anti-foaming agents, etc., can solve problems such as dare not use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0184] Comparative study of the anti-boiling properties of example 1-PGMS and ACETEM

[0185] To evaluate the ability of PGMS to control thermally induced foaming in food systems upon heating, the following procedure was performed:

[0186] program :

[0187] 3 g of the test substance are added to a 400 ml beaker. Add 40g of pasta along with 100-120g of water. The food system was then heated in a microwave oven (Panasonic NN-T994SF) at full power (1250 watts) for 3 minutes.

[0188] The time at which boiling was observed was measured visually using a stopwatch. The following results were obtained.

[0189] Table 1 - 3 g of PGMS and Acetem studied in a food system of 40 g of pasta

[0190] substance

Substance usage

Water volume in the system

boiling over

time to boil over

Acetem50-00

3g

100g

yes

90

Acetem50-00+NaCl

3g

100g

yes

90

Acetem95CO

3g

100g

yes

75

Acetem70-...

example 2

[0194] The study of the appropriate amount of example 2-PGMS

[0195] In order to determine a suitable amount of PGMS that can be applied in a food system to control boil over, the following procedure was performed.

[0196] program :

[0197] Trials were carried out as in Example 1, except that the amount of PGMS added was varied.

[0198] Table 2 - Study of different amounts of PGMS in the food system of 40g pasta

[0199] substance

[0200] Table 2 shows that in a food system with 40g pasta and 100g water, 1g of PGMS cannot effectively control boil over. In the same system, the use of PGMS in amounts greater than 3 g did not appear to have any additional effect on the control of boil over.

example 3

[0201] Example 3 - Study of the amount of water tolerable in a food system using 3 g of anti-boiling substance study

[0202] program :

[0203] The procedure followed was the same as Example 1, except that the amount of water in the food system was changed. The results are shown in Table 3.

[0204] Table 3 - Ability of PGMS and Acetem to control boil over in systems with different water volumes

[0205]

[0206] As can be seen in Table 3, Acetem was not able to effectively control boil over in food systems containing 40 g of pasta with 110 g of water or higher. In contrast, PGMS is capable of controlling boil-over in food systems containing up to 120 g of water. Therefore, PGMS can be applied to food systems that contain larger amounts of water than can be used with Acetem.

[0207] Examples 1-3 show that PGMS is superior to Acetem in controlling thermally induced foaming in food systems.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com