Arthroplasty plate

A joint and shaping technology, applied in the field of convex joint surface, repairing humeral head fractures, and arthroplasty plates, can solve the problem of difficult to achieve fine control of the bearing head, and achieve the effect of easy revision surgery and reducing the amount of interruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

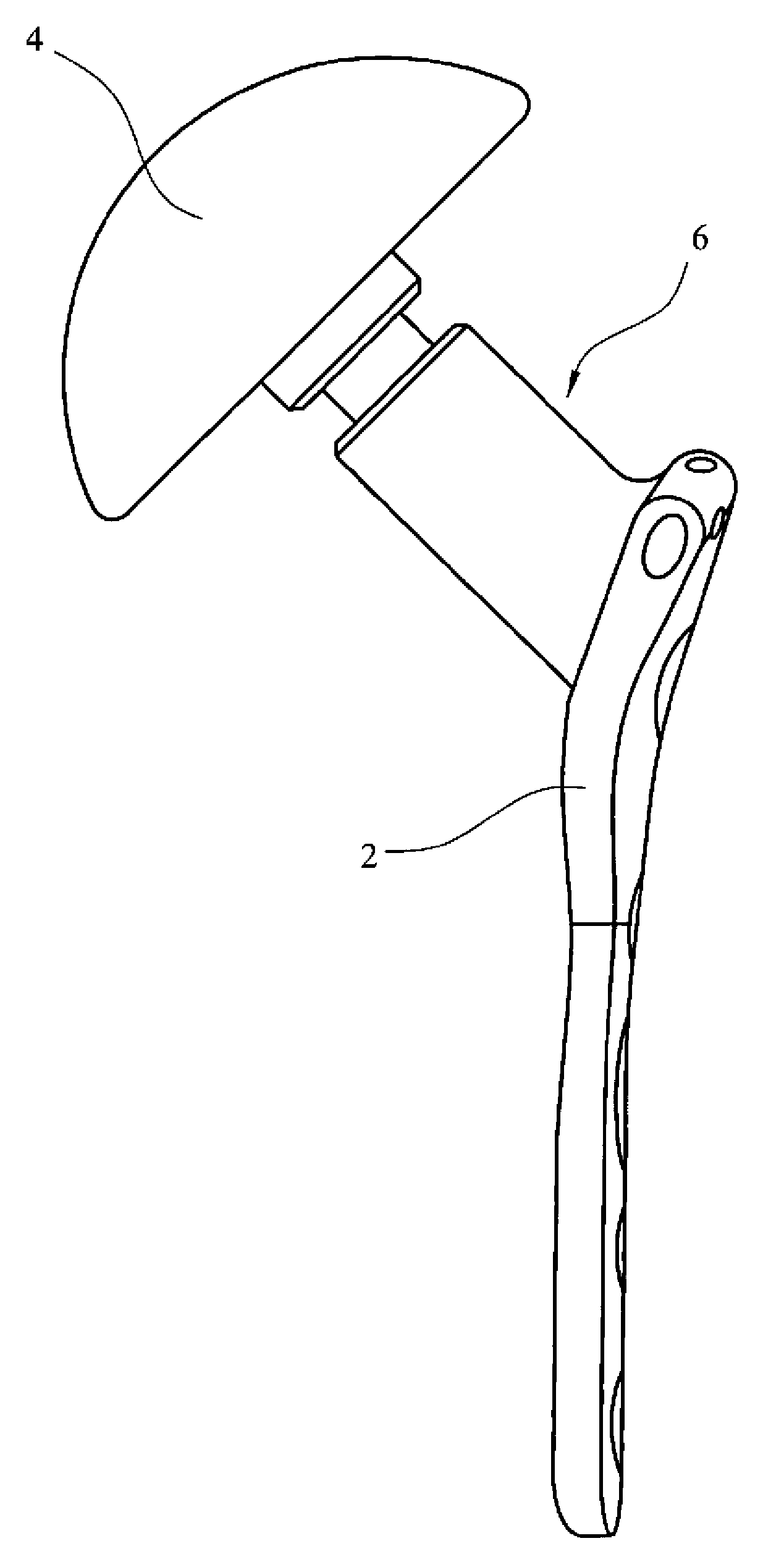

[0033] First refer to figure 1 , which is a front view of an assembled arthroplasty plate for repairing a fractured proximal humerus according to an embodiment of the present invention. The arthroplasty comprises an anchoring plate 2 for attachment to the lateral outer portion of the patient's proximal humerus. Articulation component 4 replaces the native humeral head. Articulating component 4 includes a convex load bearing surface and is sized and shaped to articulate with a native glenoid surface or an implanted glenoid prosthesis to reconfigure the shoulder joint. The articulation member 4 is coupled to the fixation plate 2 by a connection assembly 6 positioned in a bore formed in the proximal humerus.

[0034] exist figure 2 The fastening plate 2 is shown in a perspective view. The fixation plate 2 comprises an elongated body portion 8 and a head portion 10 arranged to conform to the surface of the lateral humerus. The body portion 8 incorporates a plurality of screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com