Straps with removable end connections

A technology of end connectors and connecting elements, which is applied in the direction of transmission belts, belt fasteners, belts/chains/gears, etc., can solve problems such as tension load limitations, and achieve the effect of improving strength and reducing structural burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

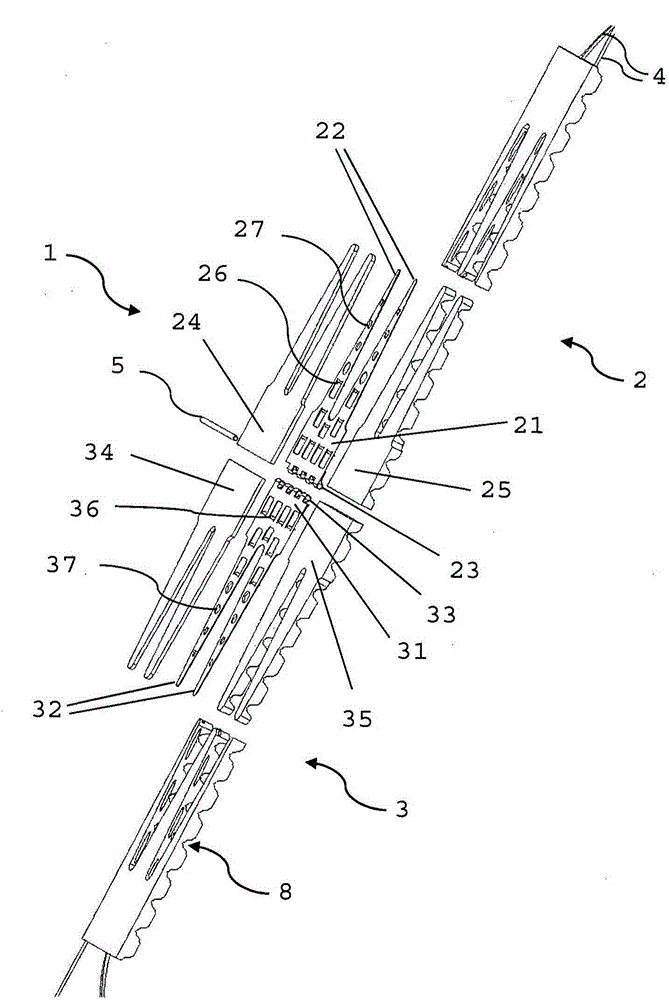

[0037] The following statement is true for the following description: If, in a figure, a reference number is shown for the sake of clarity of the drawing but is not mentioned in the directly relevant part of the description, then reference is made to the description before and after Part of the description is used to explain these reference numerals. Conversely, in order to avoid overcomplicating the figures, reference signs which are not relevant for immediate understanding are not shown in all figures. In this case, refer to the other drawings.

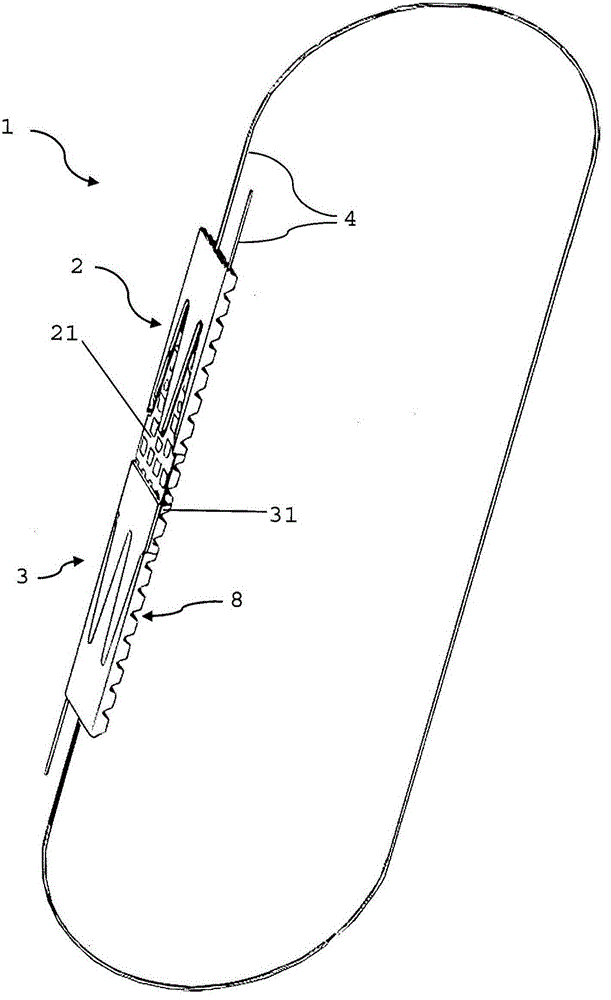

[0038] According to the invention the band 1's Figures 1 to 7 Exemplary embodiments shown in include (according tofigure 1 ) connects the first end portion 2 of the first connection element 21 and the second end portion 3 of the second connection element 31 . The two connecting elements 21 and 31 are here connected to each other via a hinge lever, as described in further detail below. In addition, the belt 1 has a tension layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com