High strength non-woven adhesive tape and preparation method thereof

A non-woven, high-strength technology, used in adhesives, rayon manufacturing, textiles and papermaking, etc., can solve problems such as poor strength and durability, non-woven tapes cannot be cleaned and split like other fabrics, and achieve performance Effects of stability, strong adhesion, high tensile strength and elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

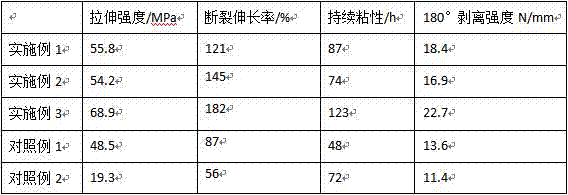

Examples

Embodiment 1

[0015] A high-strength non-woven tape, composed of the following raw materials in parts by mass: 40 parts of butadiene, 20 parts of styrene, 10 parts of polyester fiber, 10 parts of butyl acrylate, 10 parts of acrylic acid, dibutyl phthalate 0.1 part of ester, 2 parts of benzoyl peroxide, 5 parts of rosin, 1 part of malonic acid, 2 parts of N-dodecyldimethylamine, 0.1 part of dispersant glyceryl tristearate, 0.05 part of stabilizer silicone oil , 1 part of phenolic fiber, 100 parts of water.

[0016] Mix butyl acrylate and acrylic acid and heat up to 85°C, add benzoyl peroxide to carry out polymerization reaction, then add butadiene, styrene and carboxylic acid, heat up to 90°C and keep it warm for 1 hour, cool to room temperature, add phthalate Dibutyl formate, rosin, emulsifier, dispersant, stabilizer and water, stirred and mixed to obtain non-woven latex, the obtained non-woven latex was refluxed at 50°C for 24 hours, then frozen at -20°C for 50 After thawing, its color do...

Embodiment 2

[0018] A high-strength non-woven tape, composed of the following raw materials in parts by mass: 60 parts of butadiene, 30 parts of styrene, 20 parts of polyester fiber, 30 parts of butyl acrylate, 20 parts of acrylic acid, dibutyl phthalate 0.8 parts of ester, 8 parts of benzoyl peroxide, 10 parts of rosin, 10 parts of succinic acid, 6 parts of emulsifier N-dodecyldimethylamine, 1 part of dispersant monoglyceride stearate, stabilizer two 0.15 parts of methylaniline, 5 parts of phenolic fiber, and 100 parts of water.

[0019] Mix butyl acrylate and acrylic acid and heat up to 80°C, add benzoyl peroxide to carry out polymerization reaction, then add butadiene, styrene and carboxylic acid, heat up to 90°C and keep it warm for 3 hours, cool to room temperature, add phthalate Dibutyl formate, rosin, emulsifier, dispersant, stabilizer and water, stirred and mixed to obtain non-woven latex, the obtained non-woven latex was refluxed at 50°C for 24 hours, then frozen at -20°C for 50 ...

Embodiment 3

[0021] A high-strength non-woven tape, composed of the following raw materials in parts by mass: 50 parts of butadiene, 25 parts of styrene, 15 parts of polyester fiber, 20 parts of butyl acrylate, 15 parts of acrylic acid, dibutyl phthalate 0.6 parts of ester, 5 parts of benzoyl peroxide, 8 parts of rosin, 6 parts of phthalic acid, 4 parts of emulsifier N-dodecyldimethylamine, 0.5 part of dispersant monoglyceride stearate, stabilizer 0.1 part of dimethylaniline, 3 parts of phenolic fiber, and 100 parts of water.

[0022] Mix butyl acrylate and acrylic acid and heat up to 85°C, add benzoyl peroxide to carry out polymerization reaction, then add butadiene, styrene and carboxylic acid, heat up to 90°C and keep it warm for 2 hours, cool to room temperature, add phthalate Dibutyl formate, rosin, emulsifier, dispersant, stabilizer and water, stirred and mixed to obtain non-woven latex, the obtained non-woven latex was refluxed at 50°C for 24 hours, then frozen at -20°C for 50 Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com