Carpet cleaning machine

A technology for carpet cleaners and rear fuselages, applied to carpet cleaners and machine components, which can solve the problems of low correlation of function realization, uneasy and reasonable operation process, and high cost, so as to achieve reasonable function distribution, strong integrity, Easy to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

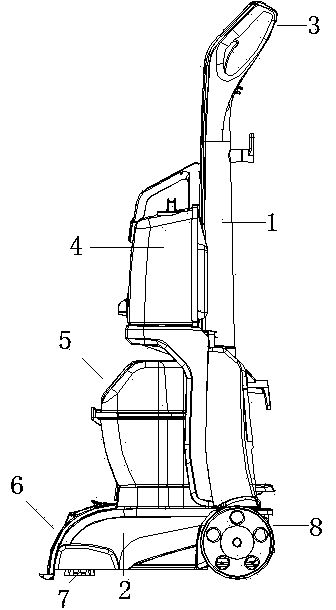

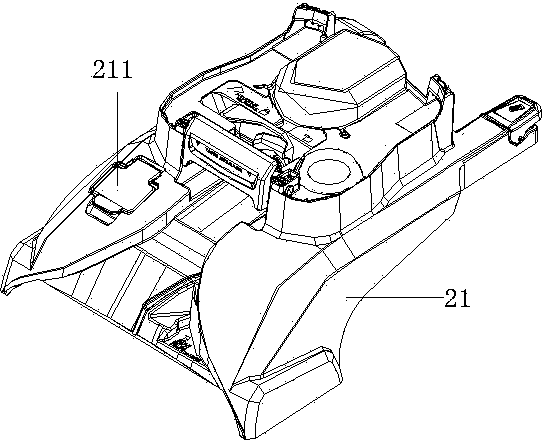

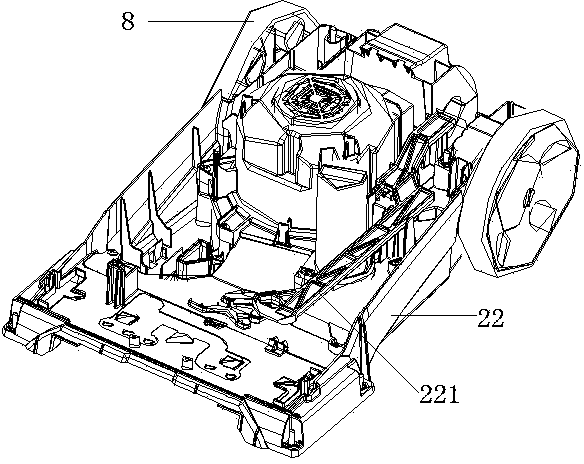

[0030] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 8A kind of carpet cleaning machine shown, comprises the rear fuselage 1 with runner 8, mop base 2, described rear fuselage 1 rear upper end is provided with operating handle 3, and described rear fuselage 1 is provided with There are a solution barrel 4 and a recovery barrel 5. The mop seat 2 is provided with a motor, and the motor pumps air to form a negative pressure source chamber in the mop seat 2. The solution barrel 4 is connected to a turbo pump. The floor mop seat 2 is also provided with a sewage suction nozzle 6 and a discharge brush 7, the discharge brush 7 is powered by a transmission pump, the sewage suction nozzle 6 communicates with the recovery bucket 5, and the recovery bucket 5 is provided with There is an air outlet pipe 523 communicating with the negative pressure source cavity, and the negative pressure source cavity communicates with the air passage in the turbo pump and the ...

Embodiment 2

[0031] Embodiment 2: The structure and implementation of this embodiment are basically the same as in Embodiment 1, the difference is that it has such Figure 5 , Figure 6 Recycle Bin 5 as shown, as in Figure 7 As shown in the water storage device 9, the recovery barrel 5 includes an upper body 51 and a lower body 52, a separation plate 53 is provided between the upper body 51 and the lower body 52, and the lower body 52 is provided with Air inlet 521, described separation plate 53 is provided with airway hole, floating stop hole 531, inner air outlet hole 532, air outlet hole 533, and described lower body 52 is provided with the air inlet that links to each other with air inlet 521 The air inlet 522 is connected to the upper body 51 through the air passage hole, the air inlet 522 is connected to the inner air outlet 532, and the lower end of the separation plate 53 is provided with a floating check valve 534 with air holes. The float spool 535 of the floating stop valve 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com