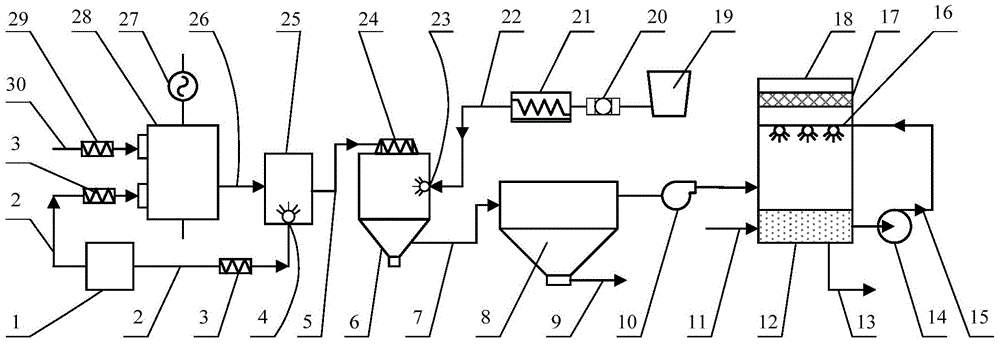

A kind of white carbon black spray drying system and method

A technology of drying system and drying method, which is applied in spray evaporation, chemical industry, climate sustainability, etc. It can solve the problems of high labor intensity, high price of heat-resistant stainless steel, and restrictions on popularization and application, and achieve low operation and maintenance costs, The effect of long continuous operation period and high failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1, aiming at a white carbon black production line with an annual output of 60,000 tons, the present invention is compared with the traditional coal-fired indirect heating hot blast stove drying process in terms of economy and environment. The prices of various resources are based on the following data: natural gas price 2.38 yuan / m 3 , the water price is 3.8 yuan / ton, the electricity price is 0.75 yuan / kWh (considering the price of natural gas power generation), the power coal price is 600 yuan / ton, and the sulfur content of coal is 1.5%.

[0064] The economic indicators of the present invention are shown in Table 1, the economic indicators of the traditional coal-fired indirect heating type hot blast stove are shown in Table 2, and the environmental indicators of the two are shown in Table 3.

[0065] Table 1 and Table 2 show that although the annual fuel cost of the present invention is as high as 62.803 million yuan, the fuel cost of the traditional coal-f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap