Multistage pulverized coal multiple-tube rotary low temperature dry distillation technology and system

A dry distillation and pulverized coal technology, applied in the field of multi-stage pulverized coal multi-tube rotary low-temperature dry distillation process and system, can solve the problems of large hot semi-coke circulation, complex process system, and difficult operation, and achieve small gas processing capacity, Enhance the effect of dry distillation and improve the effect of heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

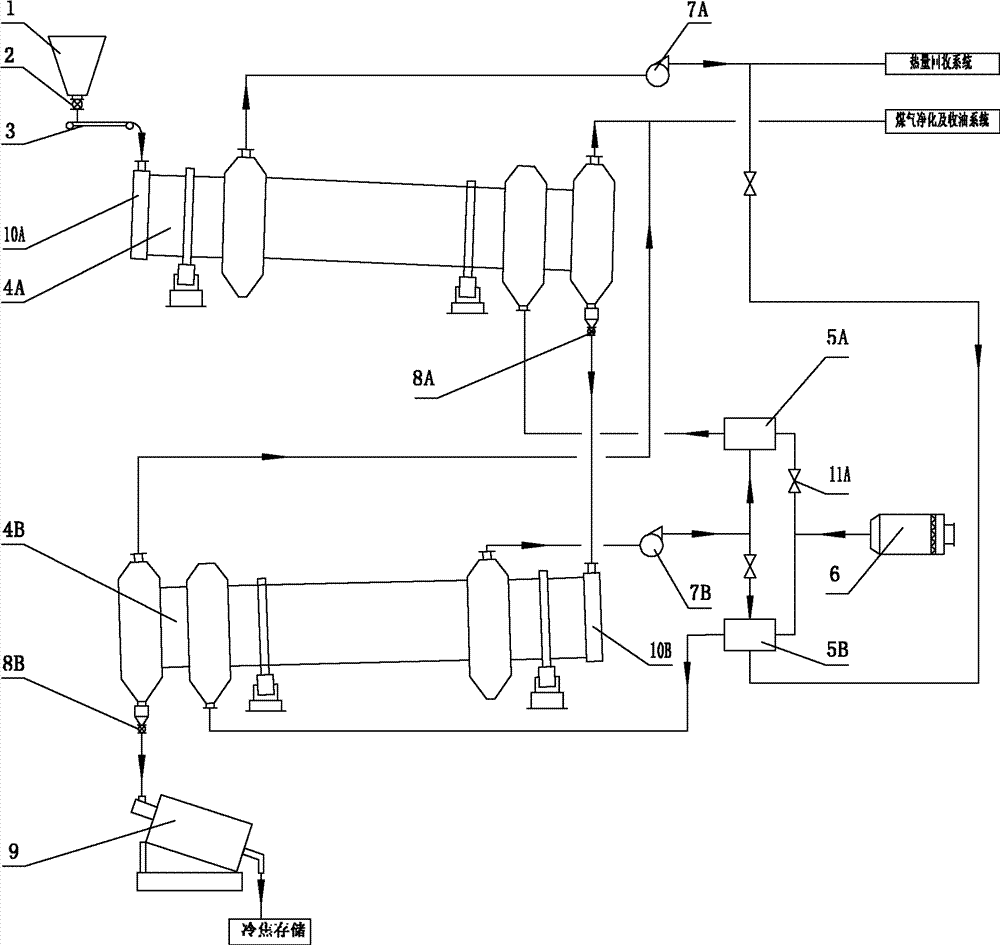

[0041] Embodiment 1, two-stage multi-tube rotary low-temperature dry distillation process and system, such as figure 1 , 3 shown.

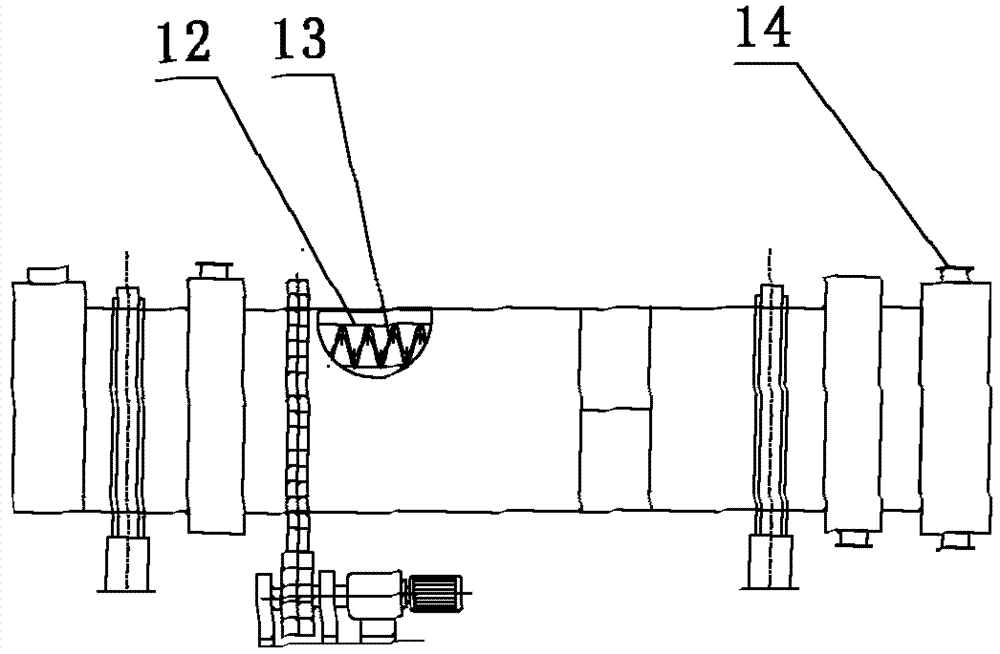

[0042] Coal process: send the pulverized coal to be retorted into the raw coal bunker 1, send it to the first-stage multi-tube pulverized coal feeder 10A through the conveying equipment 3 below the rotary feeding valve 2, and evenly enter the first-stage multi-tube rotary retort machine In the multiple dry distillation tubes 12 inside the dry distillation tube 12, the helical blades 13 in the dry distillation tube 12 move axially under the action of their own gravity and conduct indirect heat exchange with the flue gas from the first-stage air mixing chamber 5A. The flow direction of pulverized coal can be forward or reverse. Slight pyrolysis occurs after the pulverized coal absorbs heat, and the discharge temperature is controlled at 200-400°C; the pulverized coal after heating and pyrolysis by the first-stage multi-tube rotary retort 4A is sen...

Embodiment 2

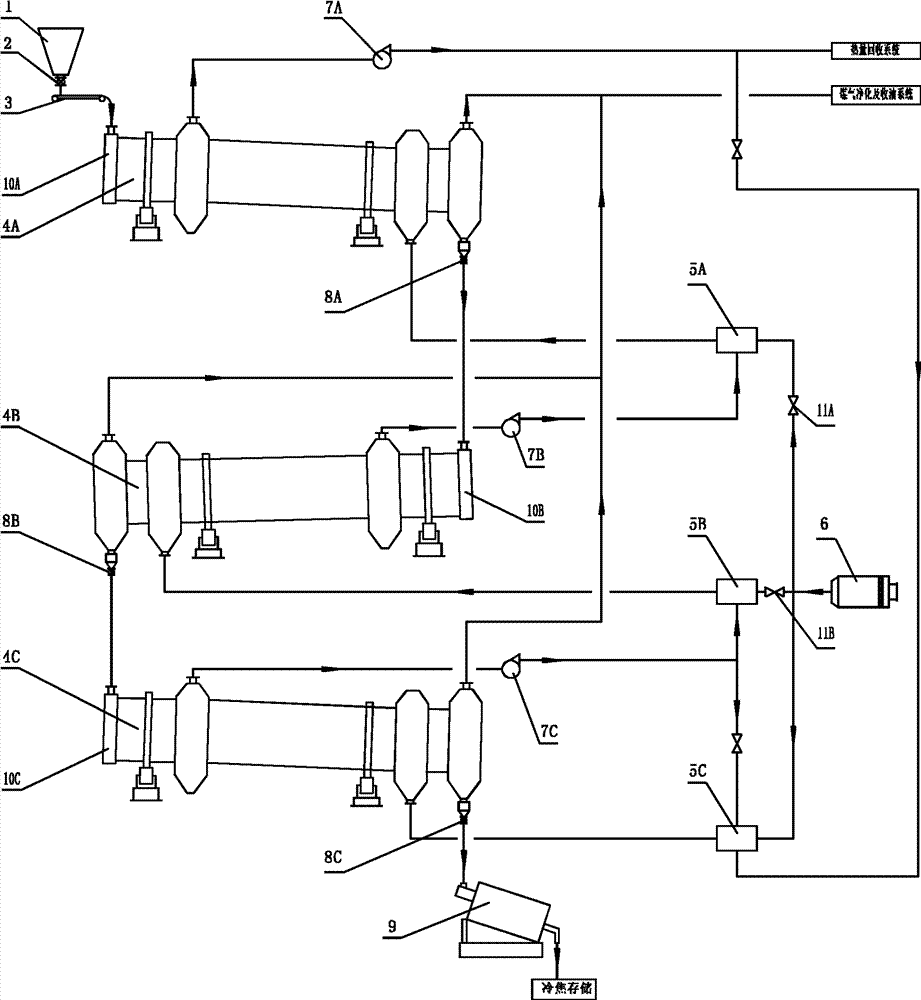

[0045] Embodiment 2: Three-stage multi-tube rotary low-temperature dry distillation process and system, such as figure 2 , 3 shown.

[0046] Coal process: the pulverized coal to be retorted is sent to the raw coal bunker 1, sent to the multi-tube pulverized coal feeder 10A through the conveying equipment 3 below the rotary feeding valve 2, and evenly enters the multiple tubes inside the first-stage multi-tube rotary retort 4A. In the first retort tube 12, the helical blade 13 in the retort tube 12 moves axially under the action of its own gravity and conducts indirect heat exchange with the flue gas from the first-stage air mixing chamber 5A. The flow direction of the flue gas and pulverized coal Can be forward or countercurrent. Slight pyrolysis occurs after the pulverized coal absorbs heat, and the discharge temperature is controlled at 200-300°C. After being heated and pyrolyzed by the first-stage multi-tube rotary retort 4A, the pulverized coal is sent to the second-sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com