Patents

Literature

30results about How to "Improve retort effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

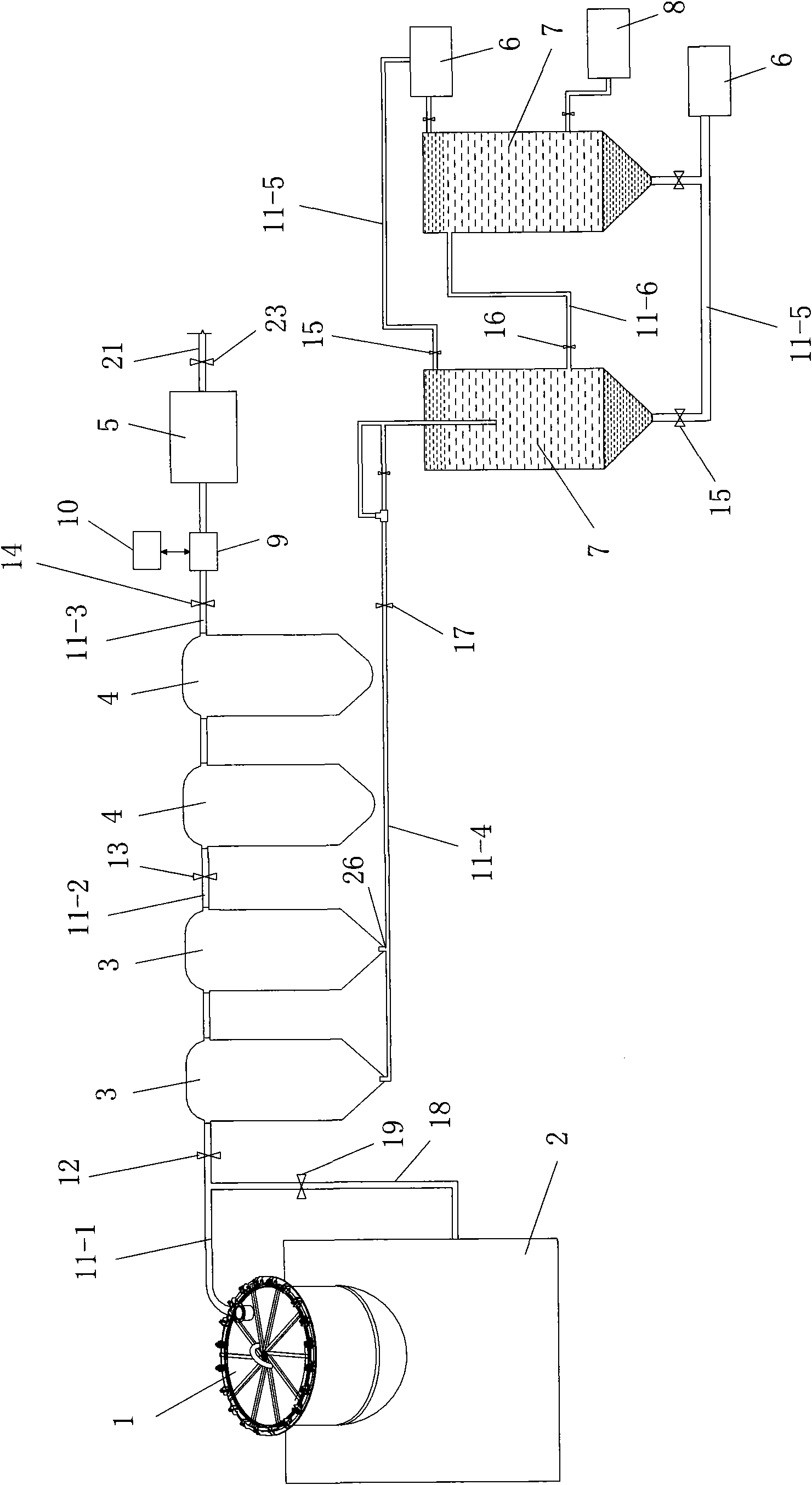

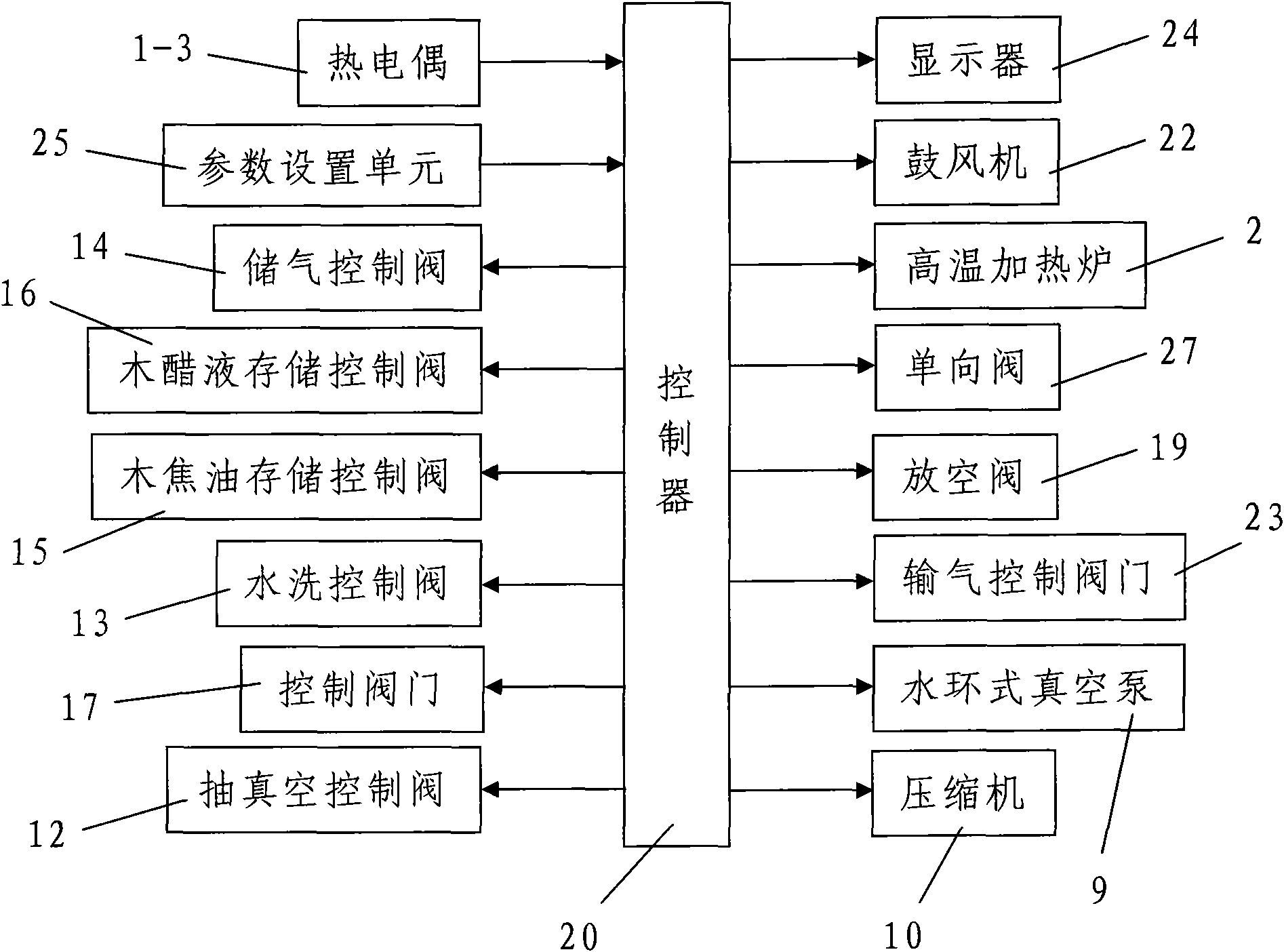

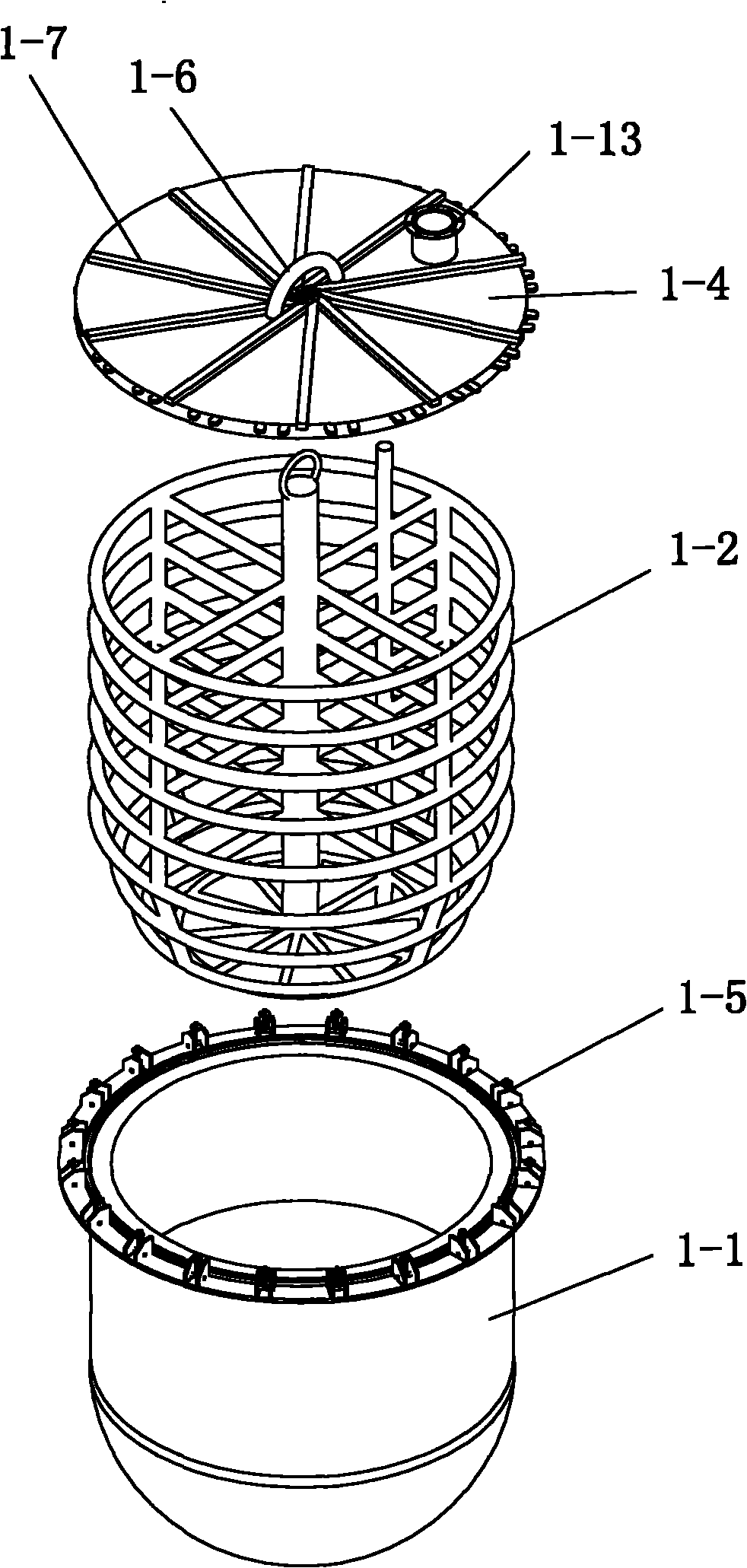

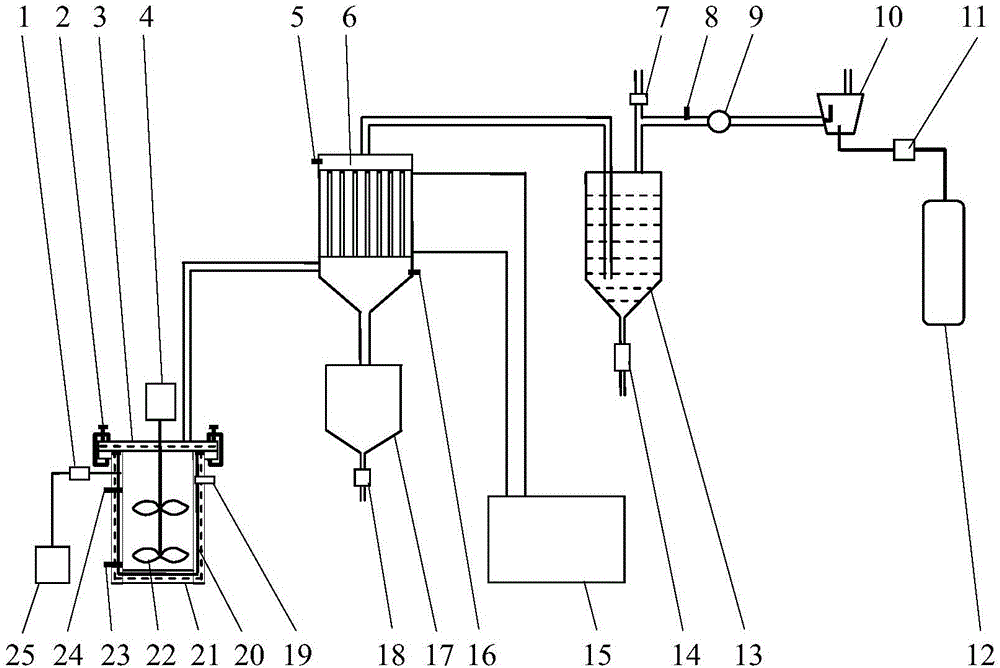

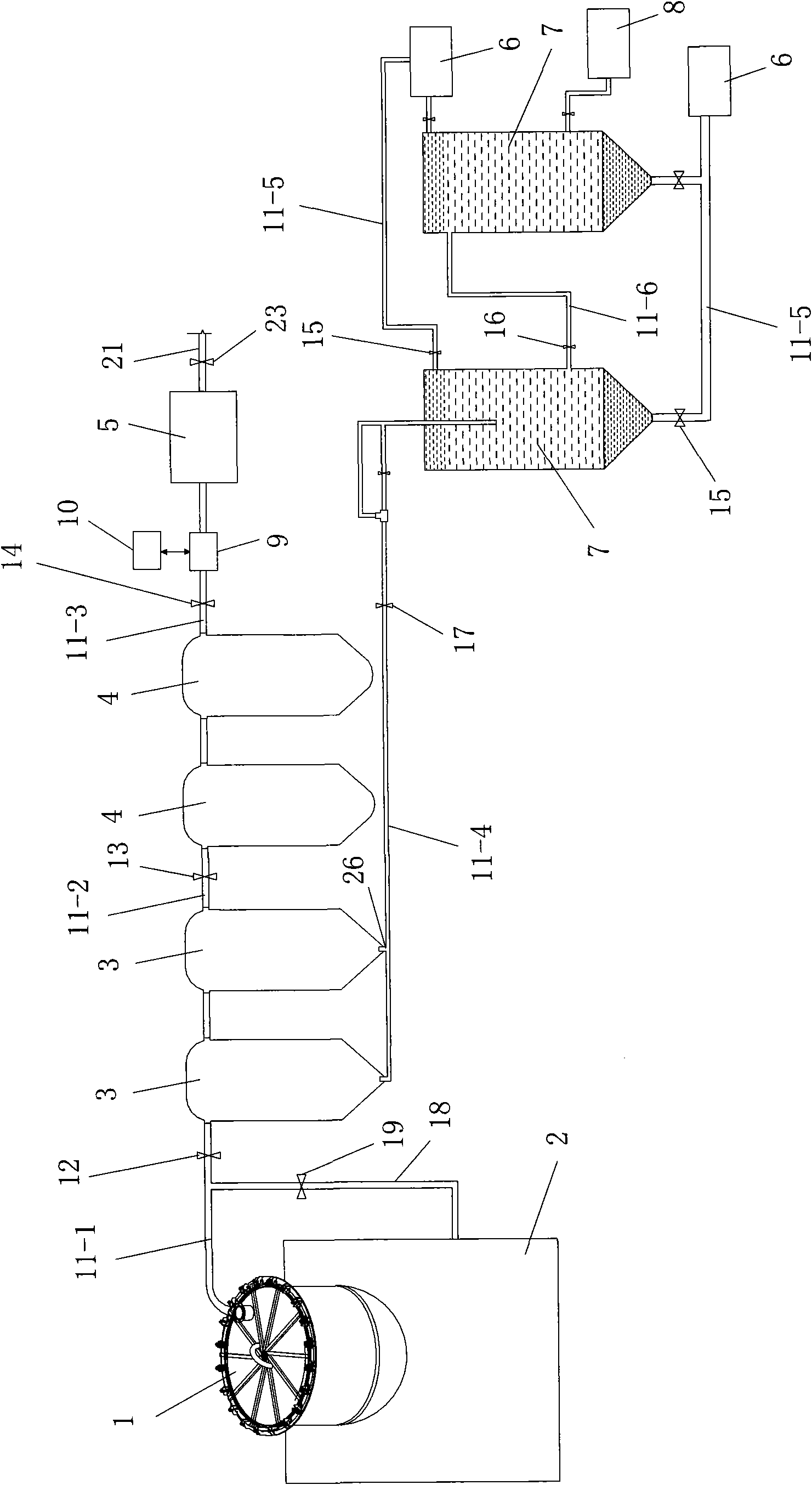

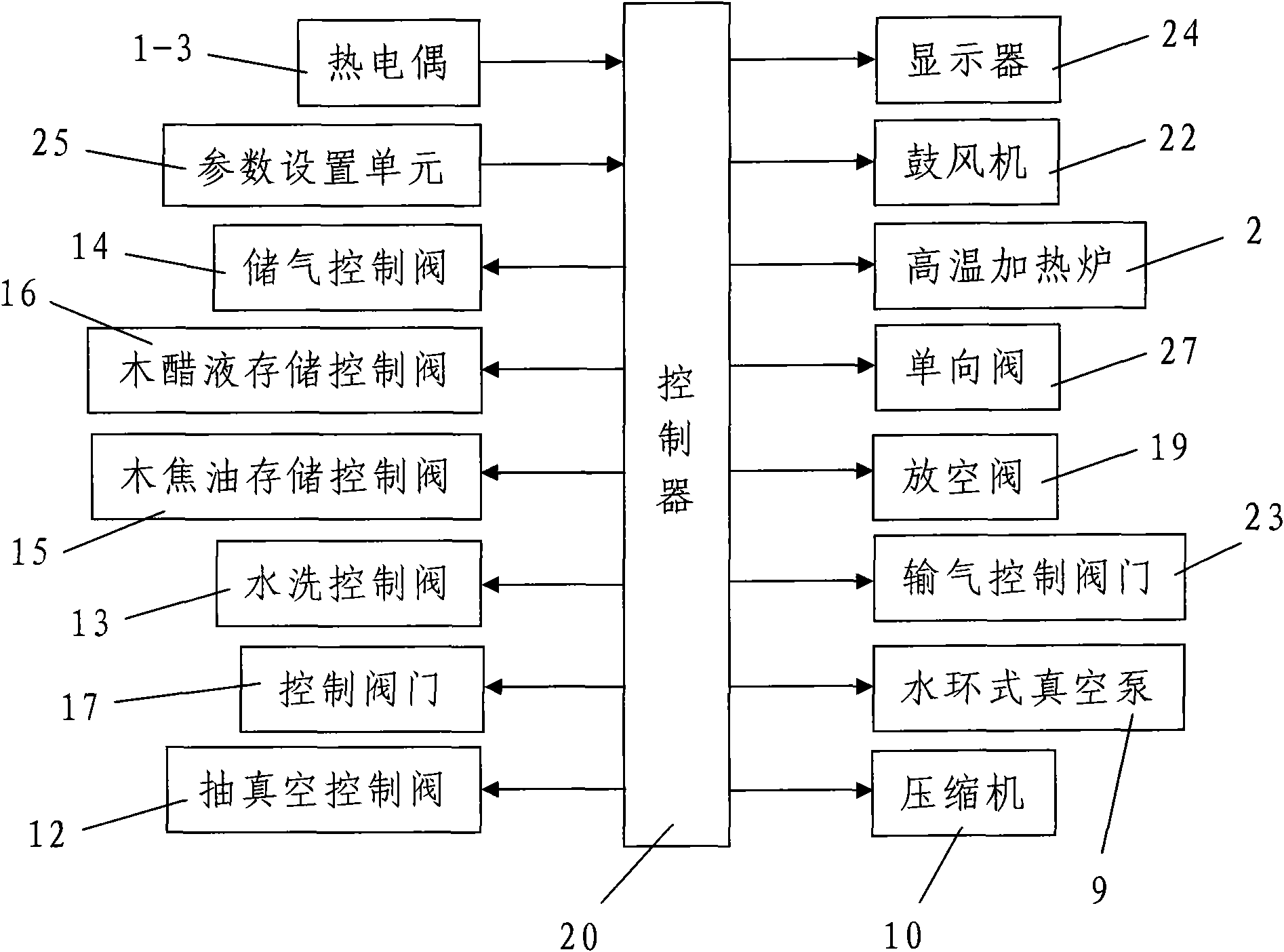

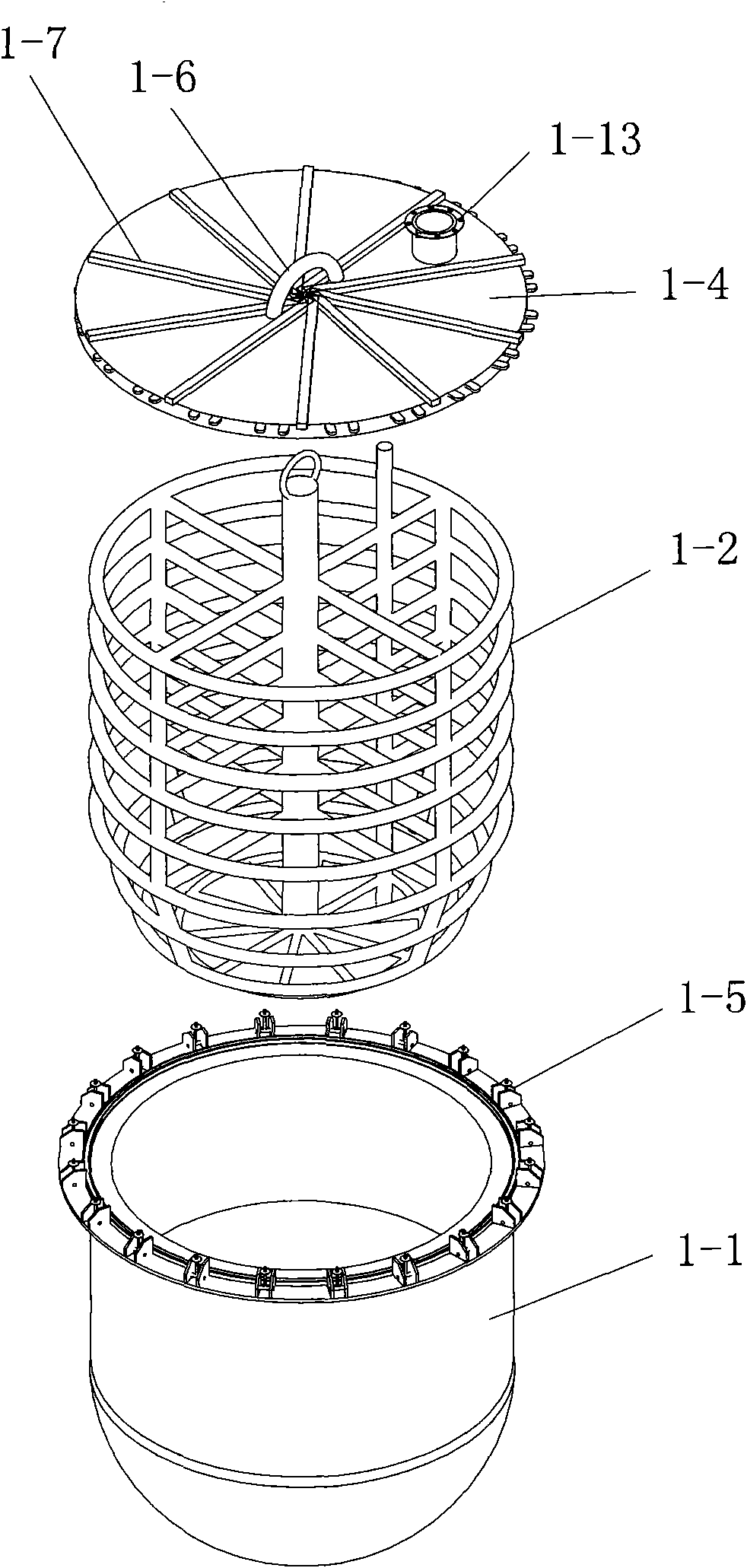

Co-production system and co-production method for biomass carbon, gas, wood tar and wood vinegar

InactiveCN101955780AFirmly connectedReasonable designBiofuelsPyroligneous acid productionSocial benefitsBiomass carbon

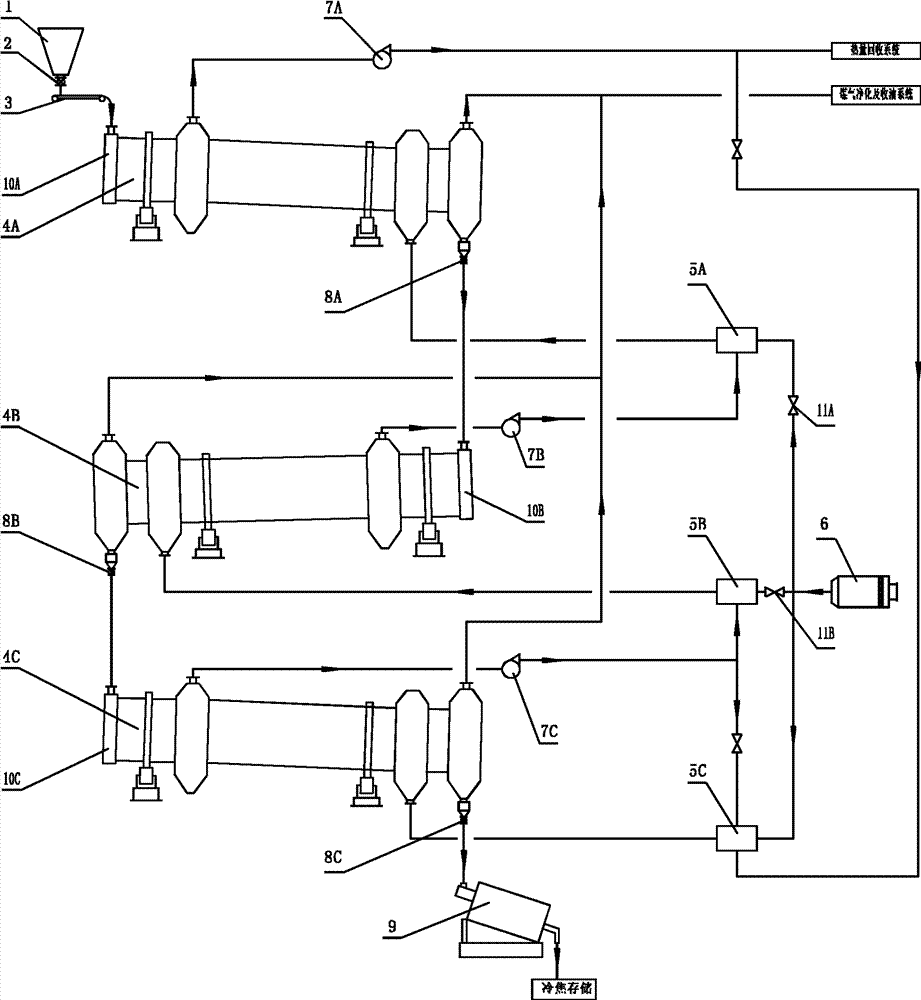

The invention discloses a co-production system and a co-production method for biomass carbon, gas, wood tar and wood vinegar. The co-production system comprises a biomass dry distillation kettle, a high-temperature heating furnace, a water cooling device, a washing device, a liquid separation device, a gas storage tank, a water-ring vacuum pump, a compressor, wood tar storage tank and a wood vinegar storage tank, wherein the liquid separation device separates wood vinegar and wood tar in the mixed liquid obtained by gas-liquid separation of the water cooling device; the co-production method comprises the following steps: 1, charging; 2, high-temperature carbonization: water cooling and gas-liquid separation, washing, gas storage and separation and storage of liquid matters; and 3, obtaining of the biomass carbon after the high-temperature carbonization. The co-production system for the biomass carbon, gas, wood tar and wood vinegar has the advantages of reasonable design, convenient processing, simple mounting arrangement, easy operation and good effect; and the co-production method has the advantages of convenient realization, high yield, low cost, fast co-production and relatively high production purity and has obvious economic and social benefits and wide popularization and application prospect.

Owner:陕西亿鑫生物能源科技开发有限公司

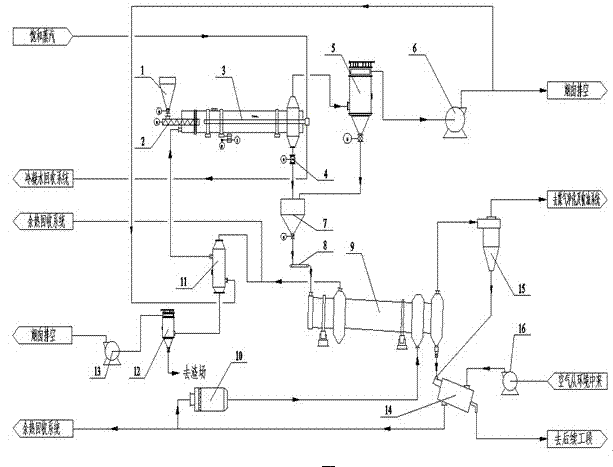

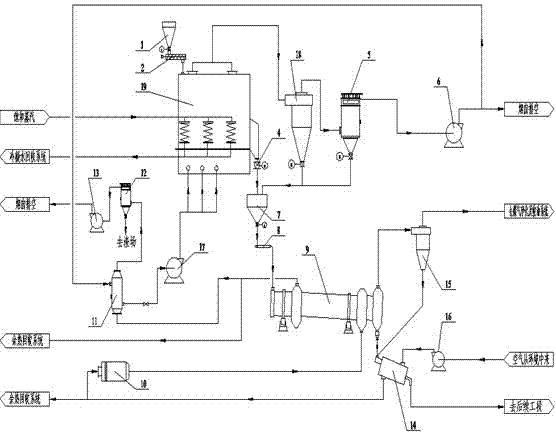

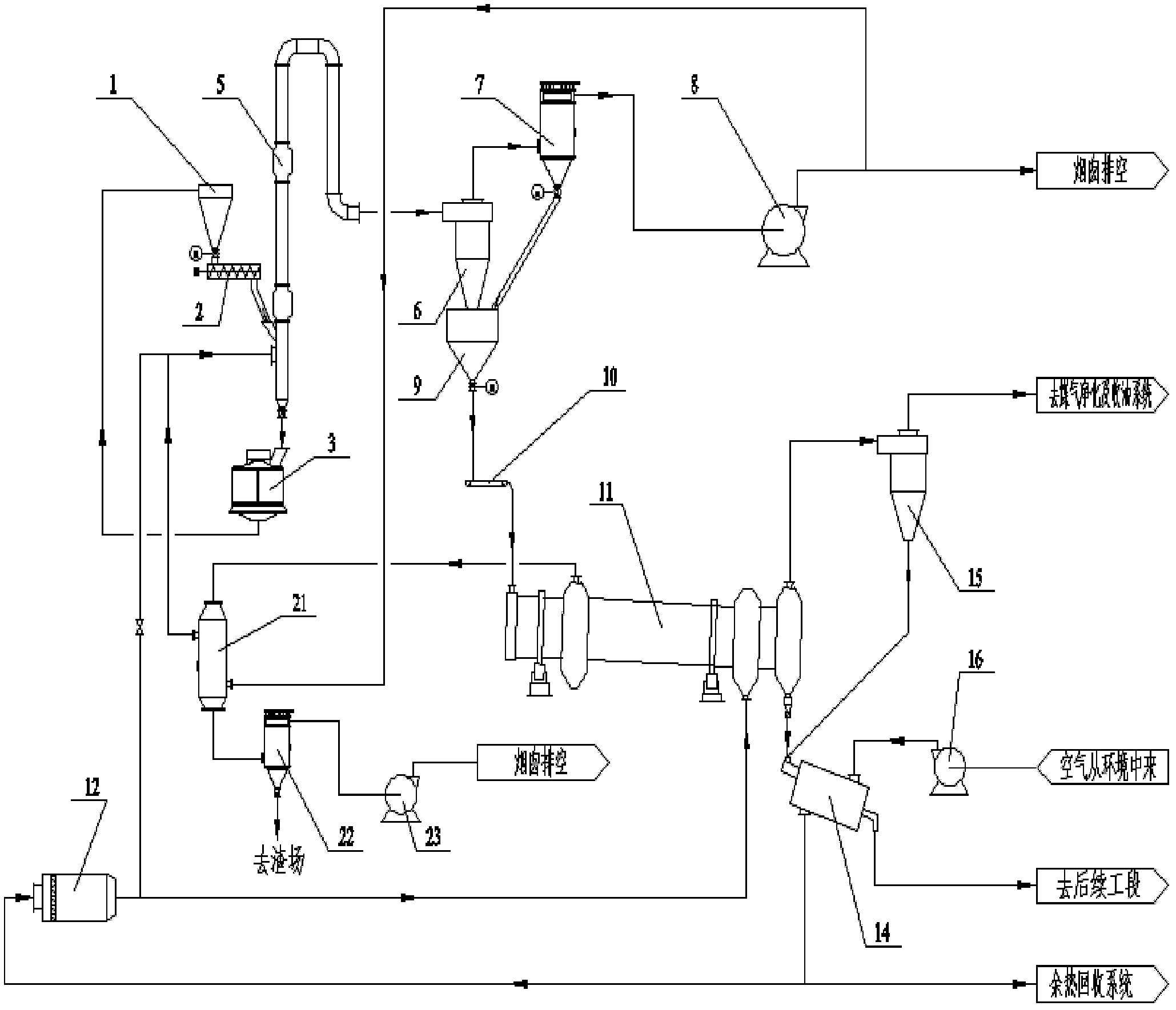

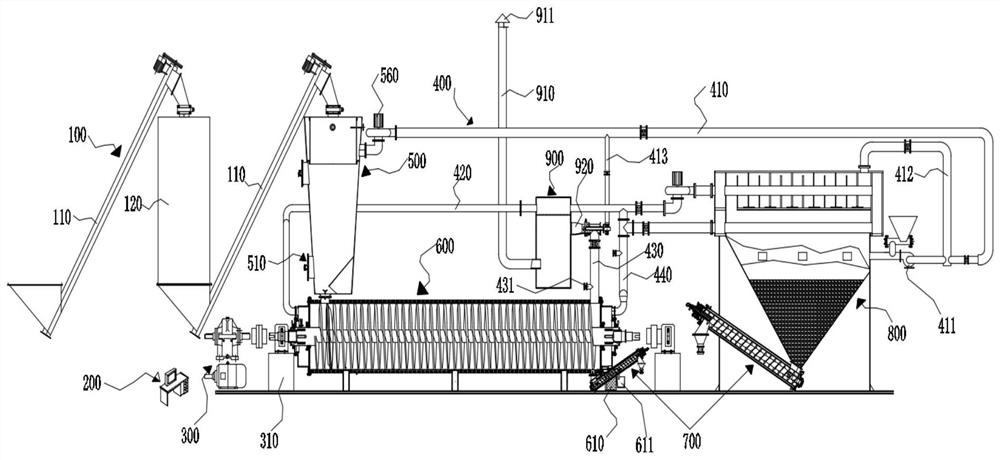

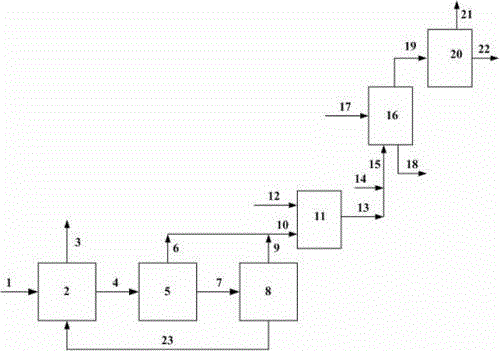

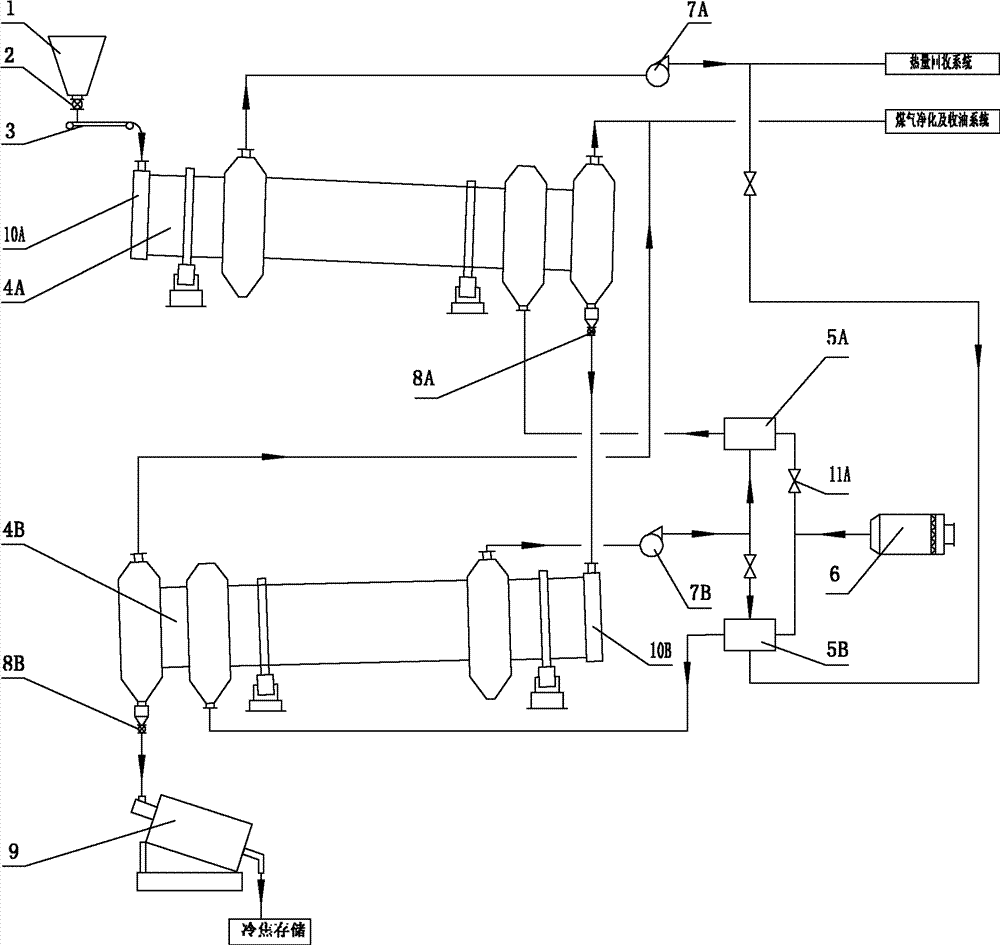

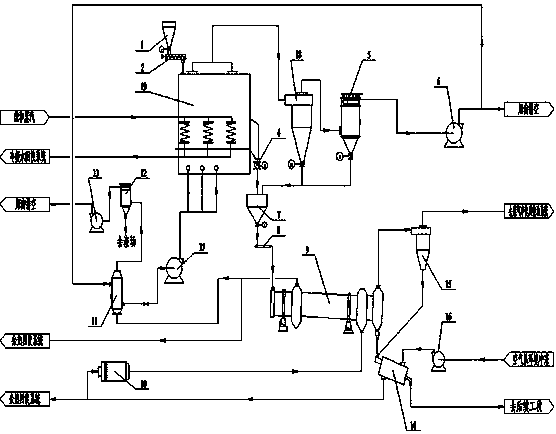

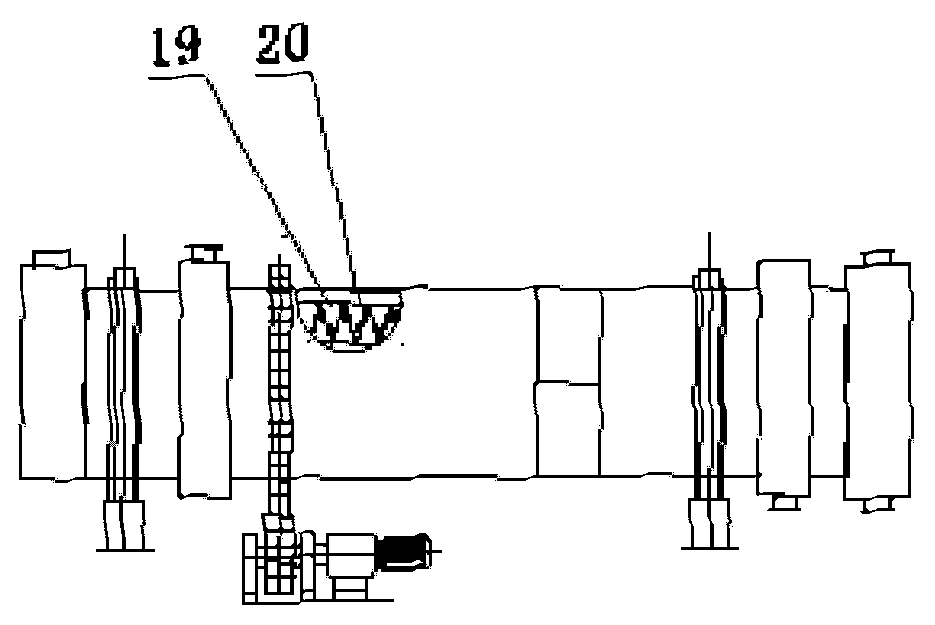

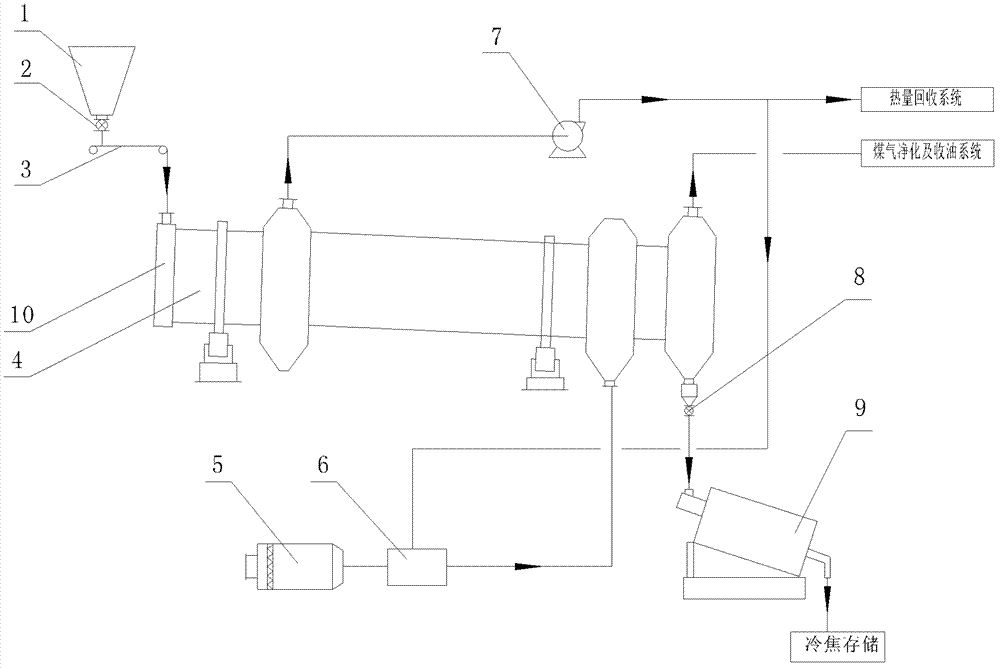

Drying and dry distillation combined quality improving process and system for low rank coal

The invention discloses a drying and dry distillation combined quality improving process and a drying and dry distillation combined quality improving system for low rank coal, which are used for overcoming the defects existing in the prior art and are particularly suitable for drying and dry distillation combined quality improvement of brown coal with high water content or other low rank coal such as long flame coal, non-caking coal or weakly caking coal, gas coal and the like. In the process, a combined quality improving method in which a steam revolving drier for drying and a multi-pipe revolving low-temperature dry distiller for dry distillation are provided is adopted, so that the problems of large coking wastewater handling capacity, large coal gas handling capacity and the like existing in a pure dry distillation process are solved. The drying and multi-pipe revolving low-temperature dry distillation combined quality improving process provided by the invention has the advantages of high energy utilization ratio, safe and stable systems, small dry distillation gas handling capacity, small coking wastewater handling capacity, high tar yield, high coal gas heat value and the like.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

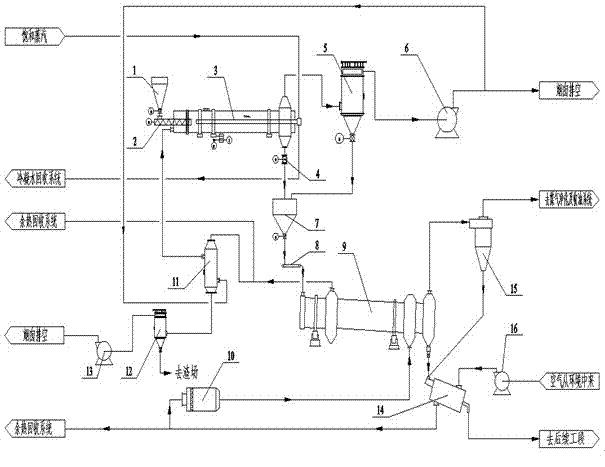

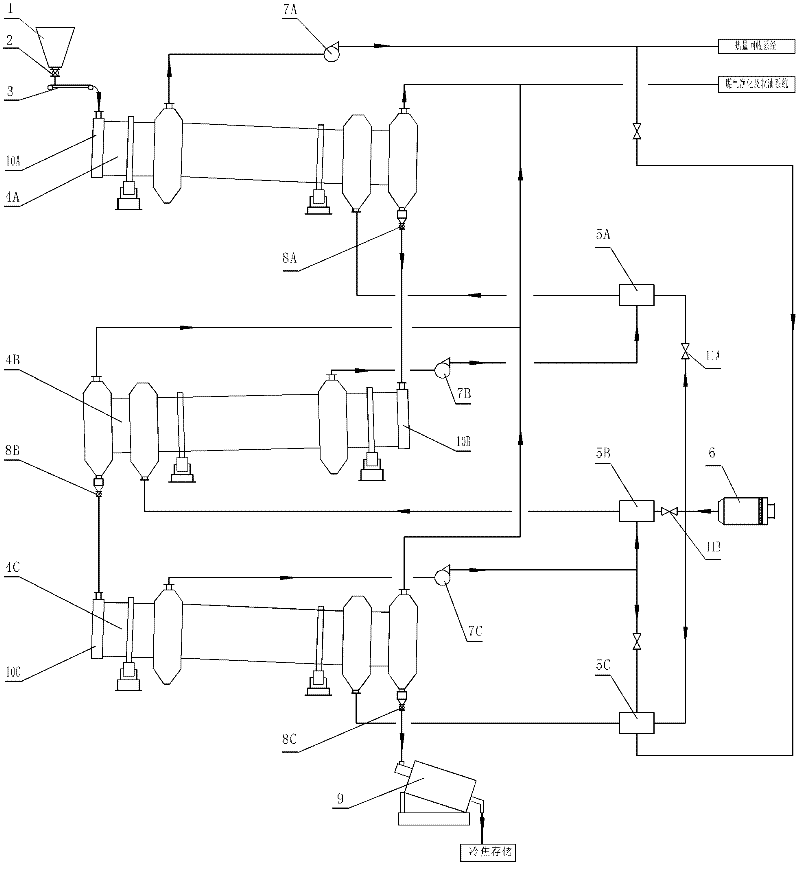

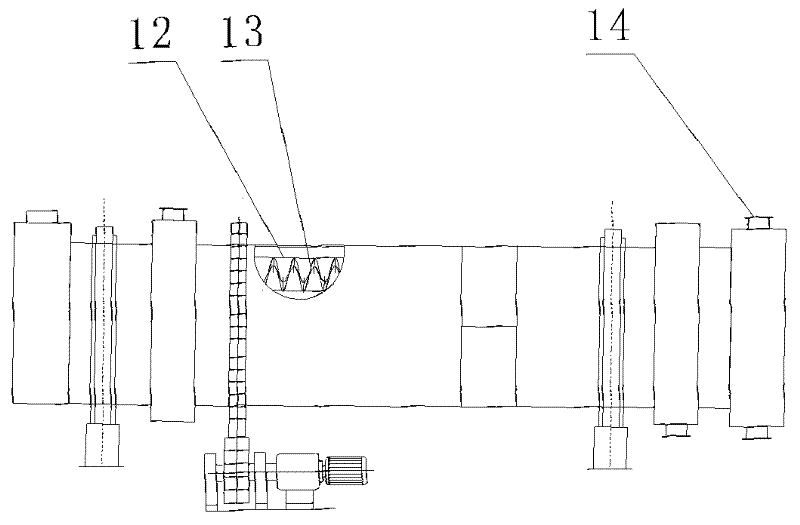

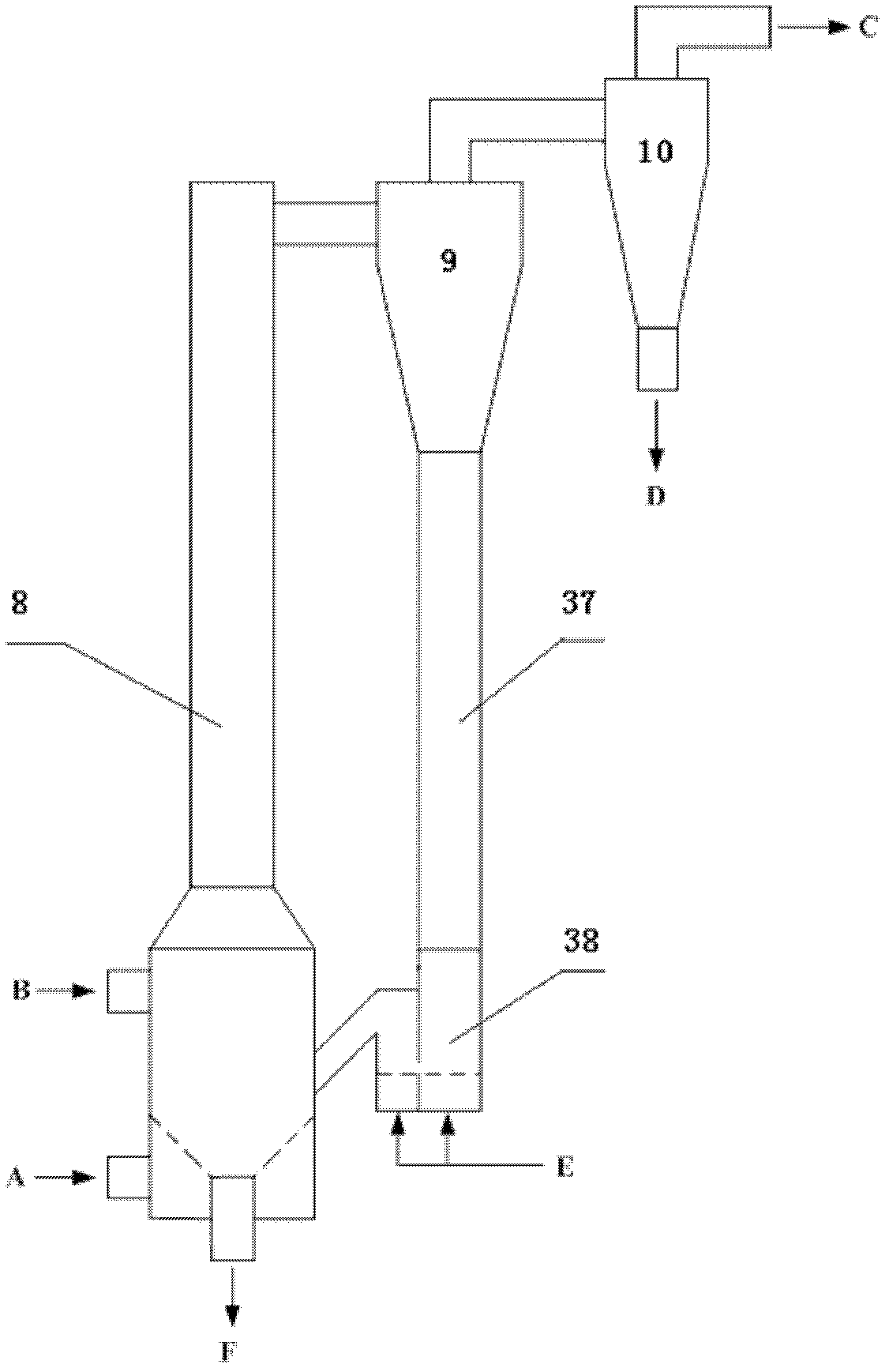

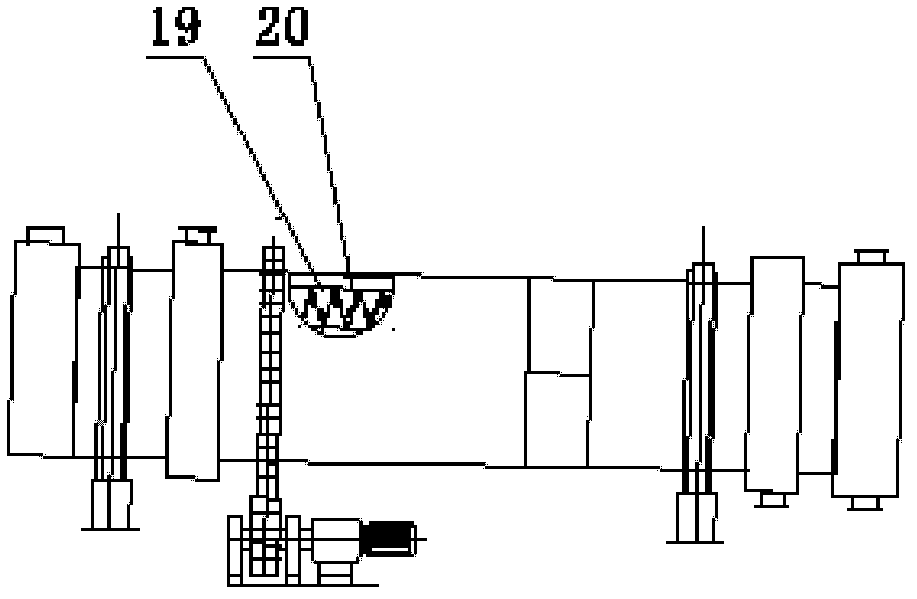

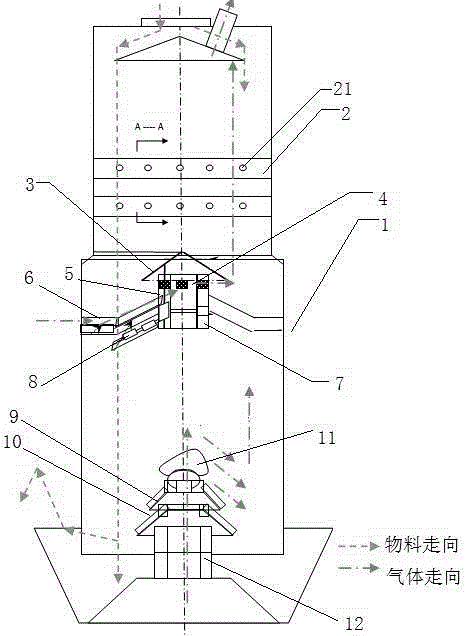

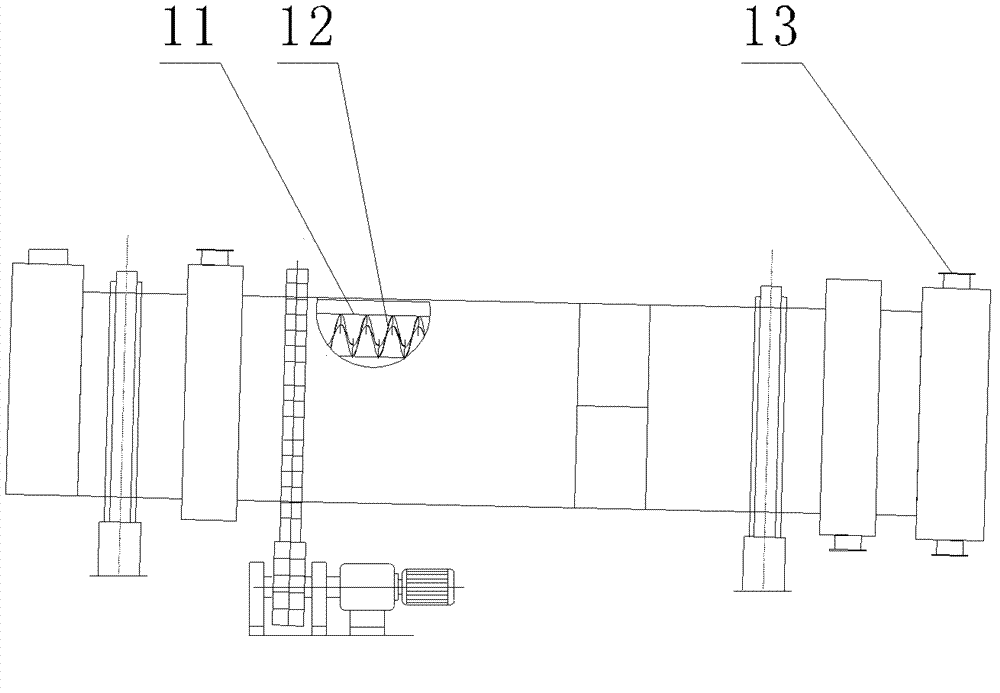

Multistage pulverized coal multiple-tube rotary low temperature dry distillation technology and system

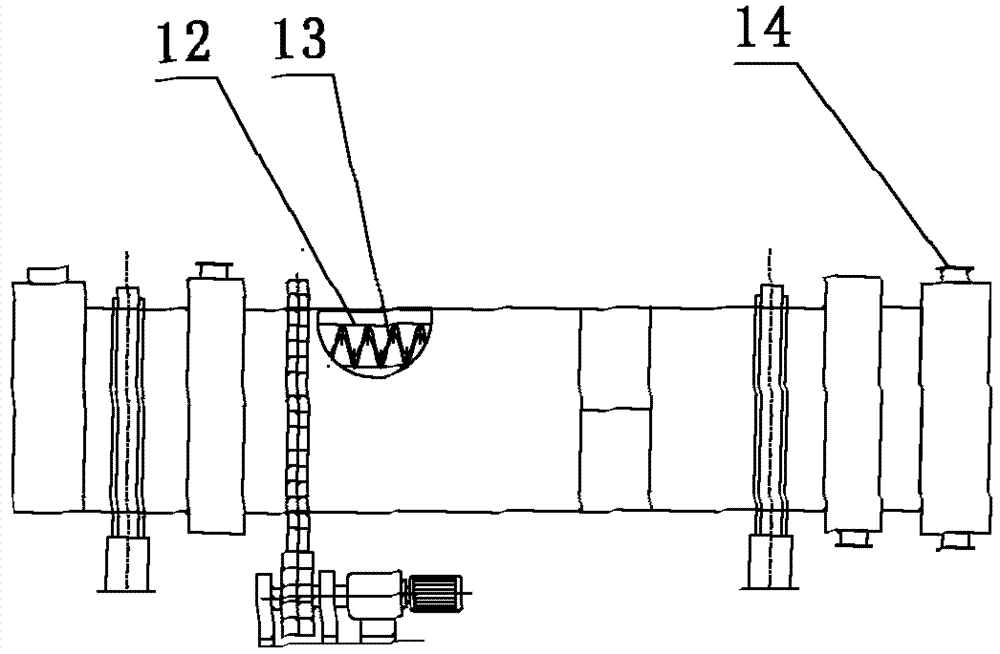

ActiveCN102358841AEasy to handleIncrease the heat exchange areaIndirect heating destructive distillationSpecial form destructive distillationCaloric valuesHelical blade

The invention discloses a multistage pulverized coal multiple-tube rotary low temperature dry distillation technology and system. The multiple-tube rotary dry distillation machine multistage (two stages or more) series connection process is adopted to perform low temperature dry distillation on pulverized coal; a plurality of dry distillation tubes are arranged in the multiple-tube rotary dry distillation machine to disperse coal powder, a helical blade is arranged in each dry distillation tube to guide and disturb coal and reinforce the dry distillation effect and increase the dry distillation effective area, the technology has the advantages of large pulverized coal treatment capacity, large dry distillation gas treatment capacity, low tar and dust contents, high coal gas caloric value and the like; the chemical raw materials generated in the low temperature dry distillation process of bituminous coal and low-price pulverized coal can be recycled extremely, the comprehensive utilization rate of coal is increased; and semicoke powder and coal gas with high calorific value can be produced through the low temperature dry distillation of bituminous coal and low-price pulverized coal.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

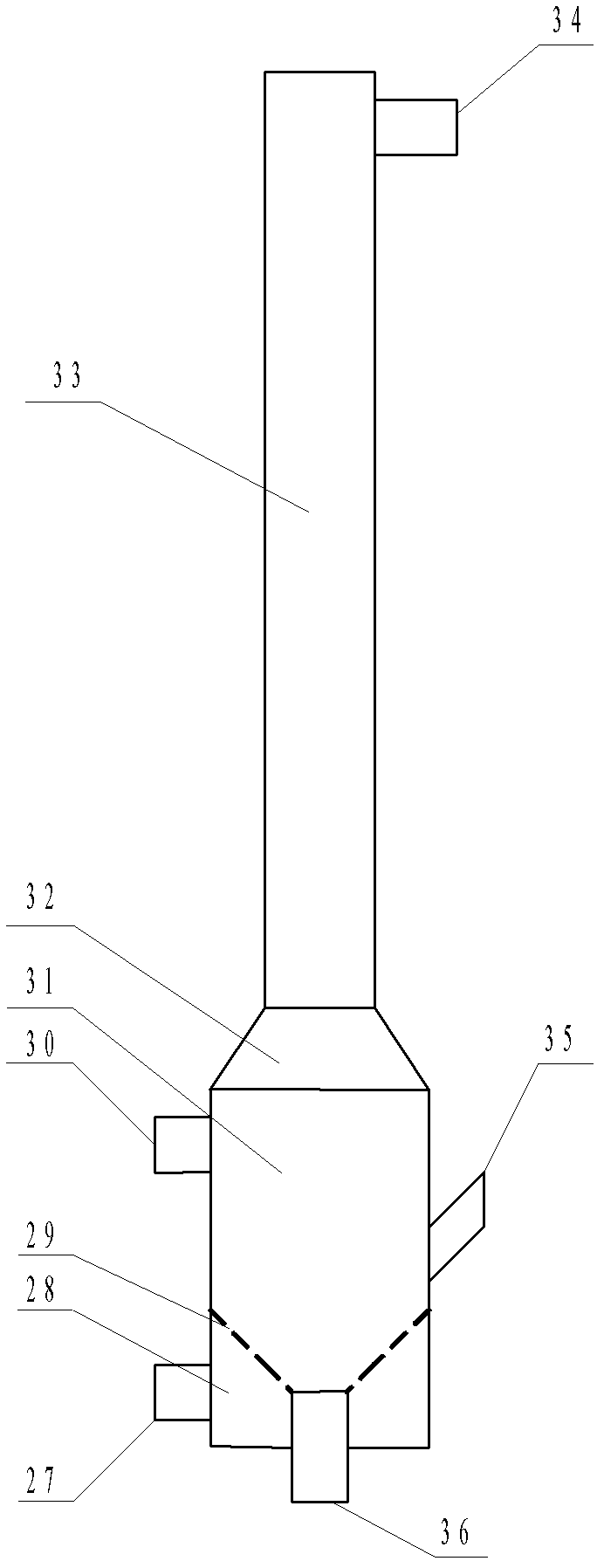

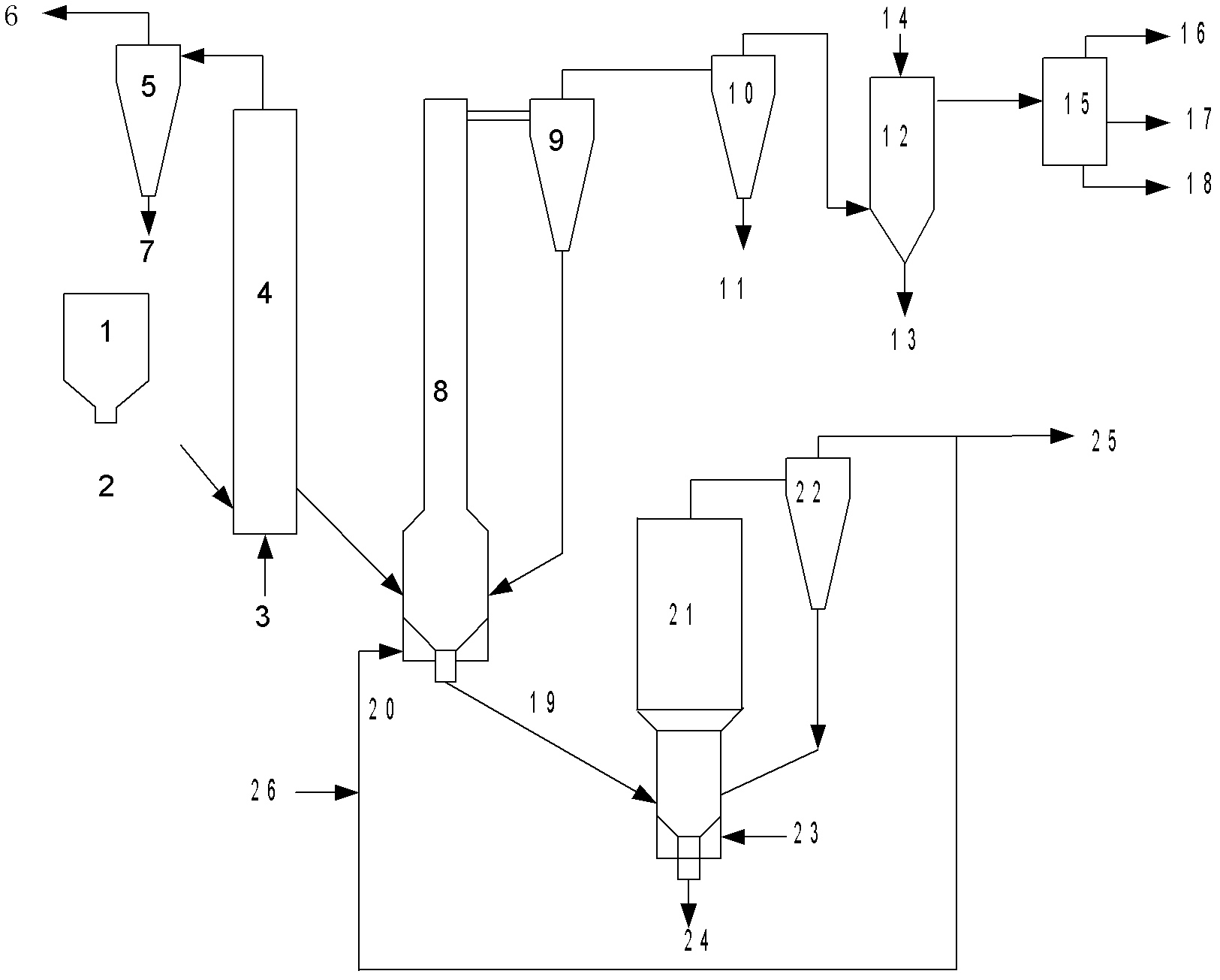

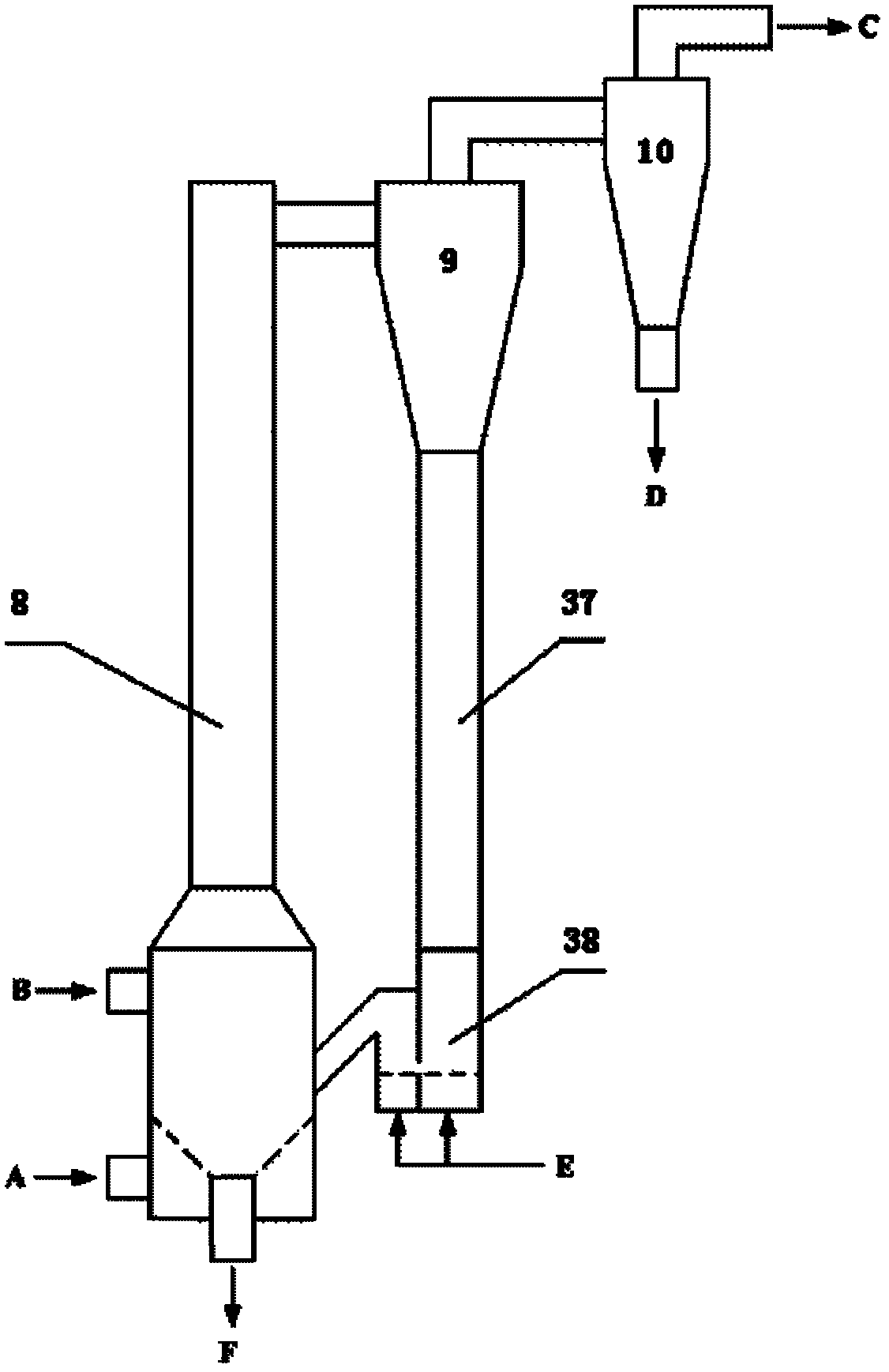

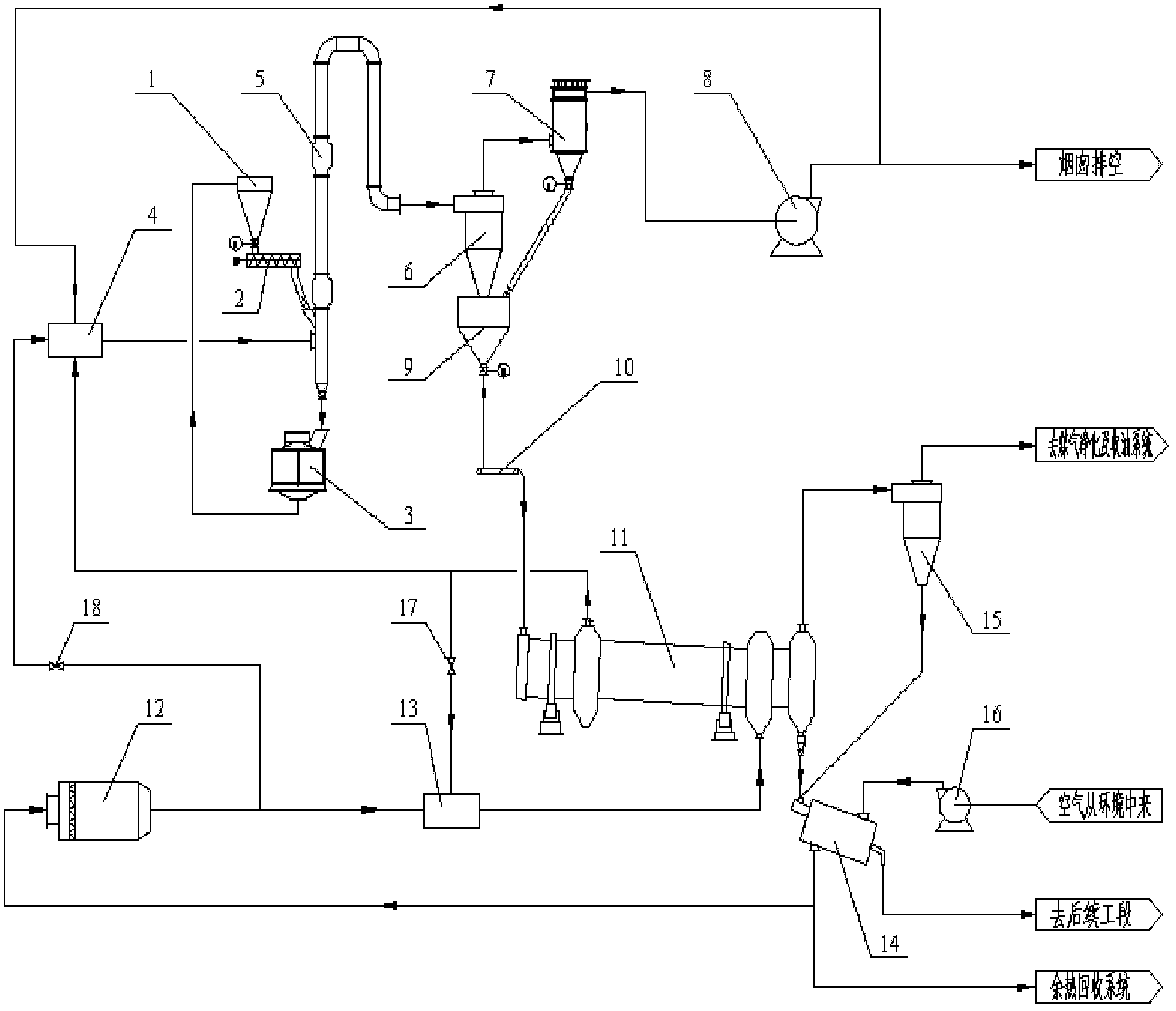

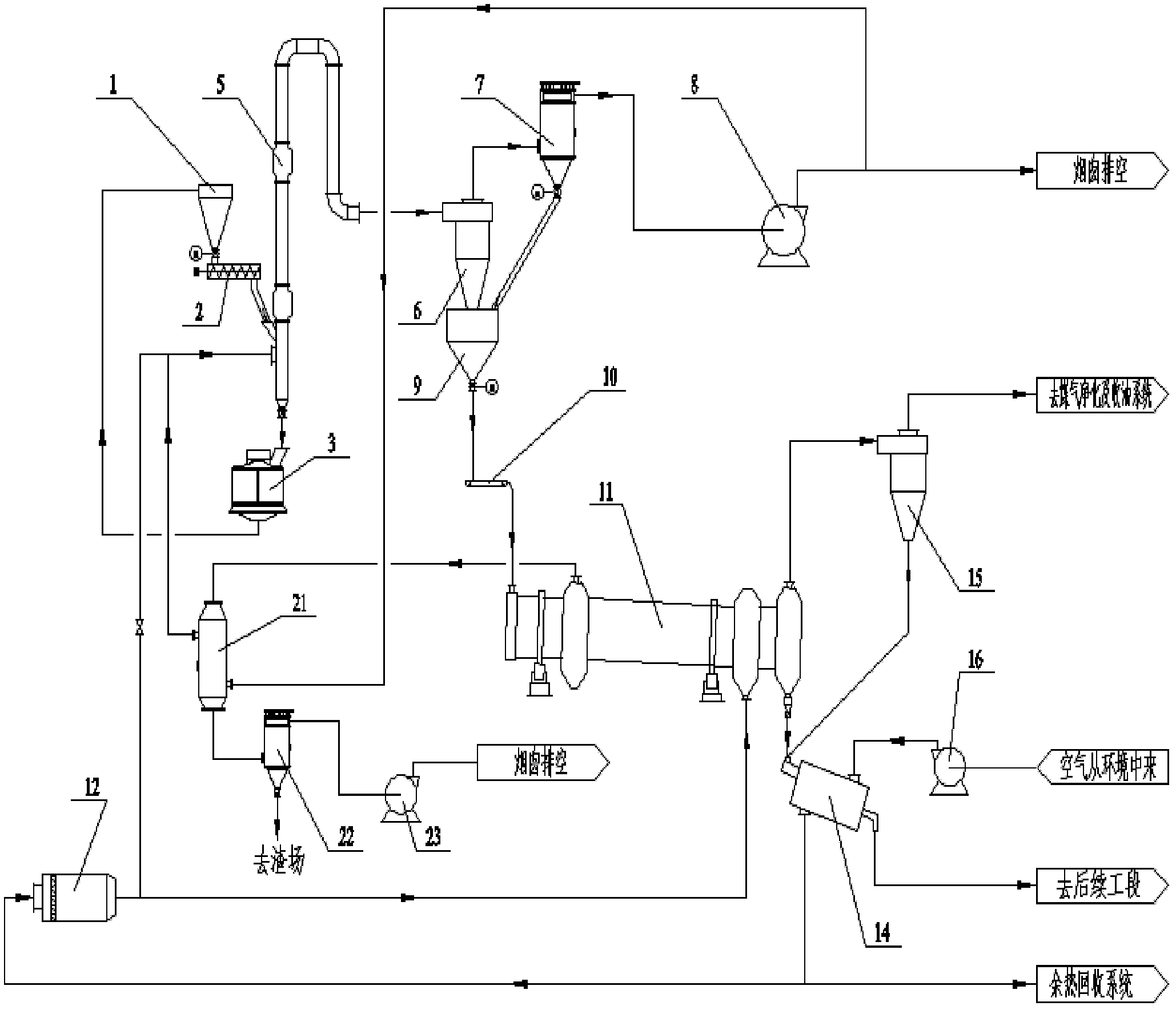

Fluidized bed low-temperature destructive distillation system and low-temperature destructive distillation method of low-rank coal

InactiveCN103160299AExtended stayHigh solid contentDirect heating destructive distillationSpecial form destructive distillationPartial hydrogenationHydrogen atmosphere

The invention provides a fluidized bed low-temperature destructive distillation system and a low-temperature destructive distillation method of low-rank coal. According to the method, a mixed gas of hot coal gas produced by a gasification furnace and circulation cold coal gas is adopted as a hot carrier and a fluidizing gas of a destructive distillation reaction. A hydrogen atmosphere of coal gas can provide a partial hydrogenation effect, such that obtained tar has the advantages of high light component content, good quality, high thermal efficiency, and high yield. Also, with the method, a two-stage low-temperature destructive distillation reactor is adopted, such that the retention time of solid particles in the reactor is increased, destructive distillation effect is improved, high solid content in the bed can be maintained, and operation stability can be maintained. The invention also provides a low-temperature destructive distillation reactor. The low-temperature destructive distillation reactor is the two-stage low-temperature destructive distillation reactor, such that the retention time of solid particles in the reactor is increased, and destructive distillation effect is improved. With the two-stage low-temperature destructive distillation reactor, high solid content in the bed can be maintained, and operation stability can be maintained.

Owner:CHINA COAL ENERGY HEILONGJIANG COAL CHEM +1

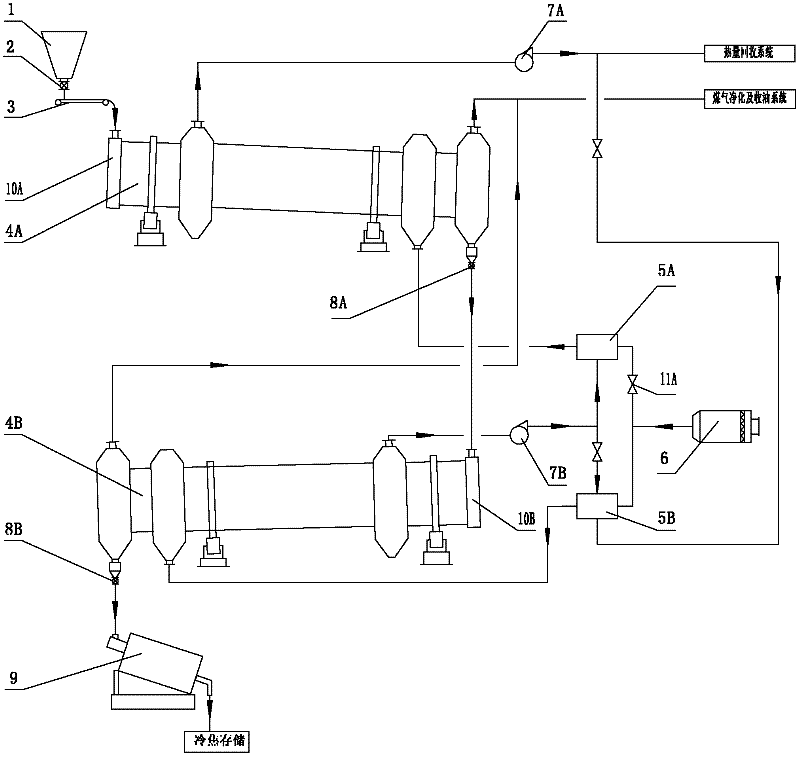

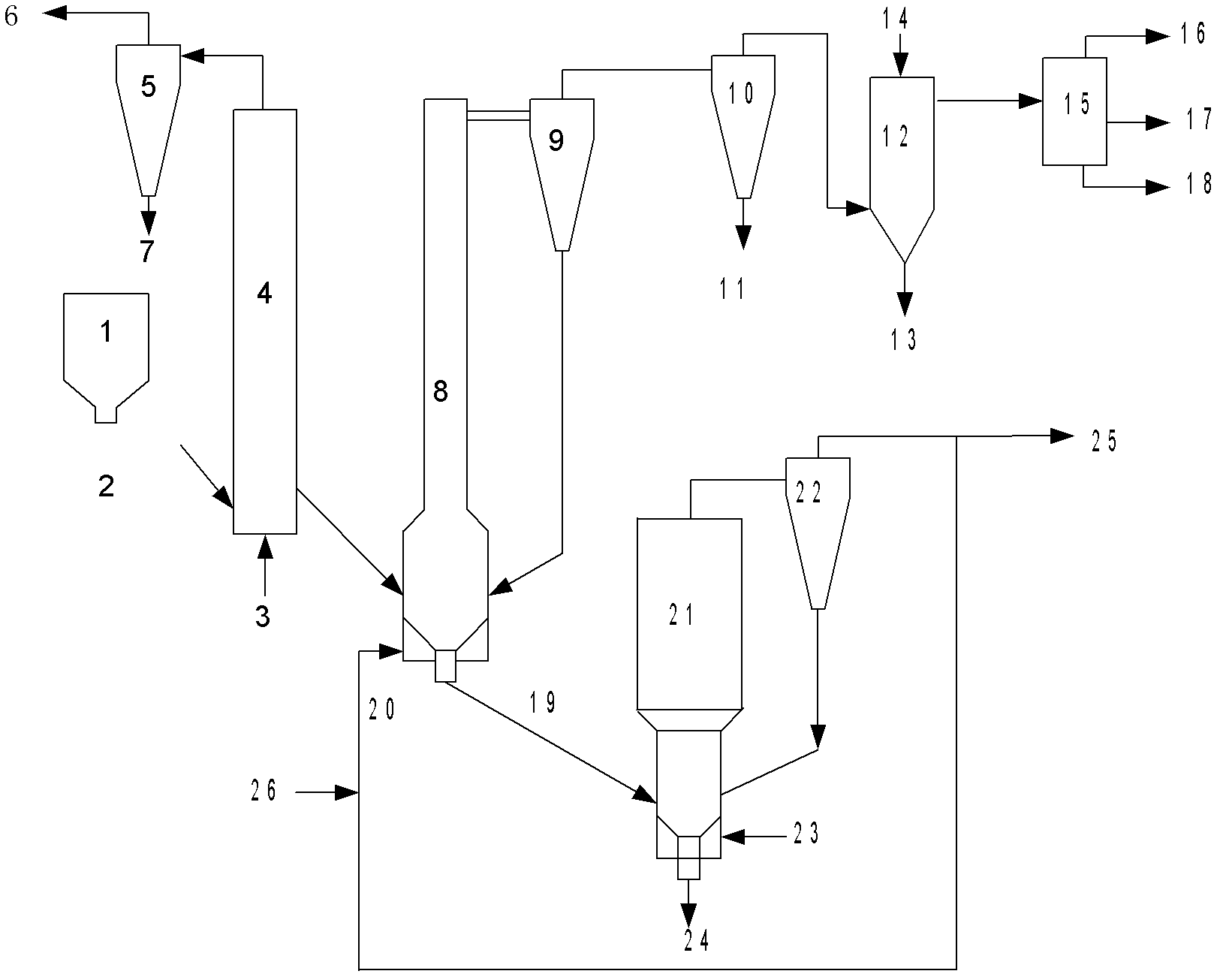

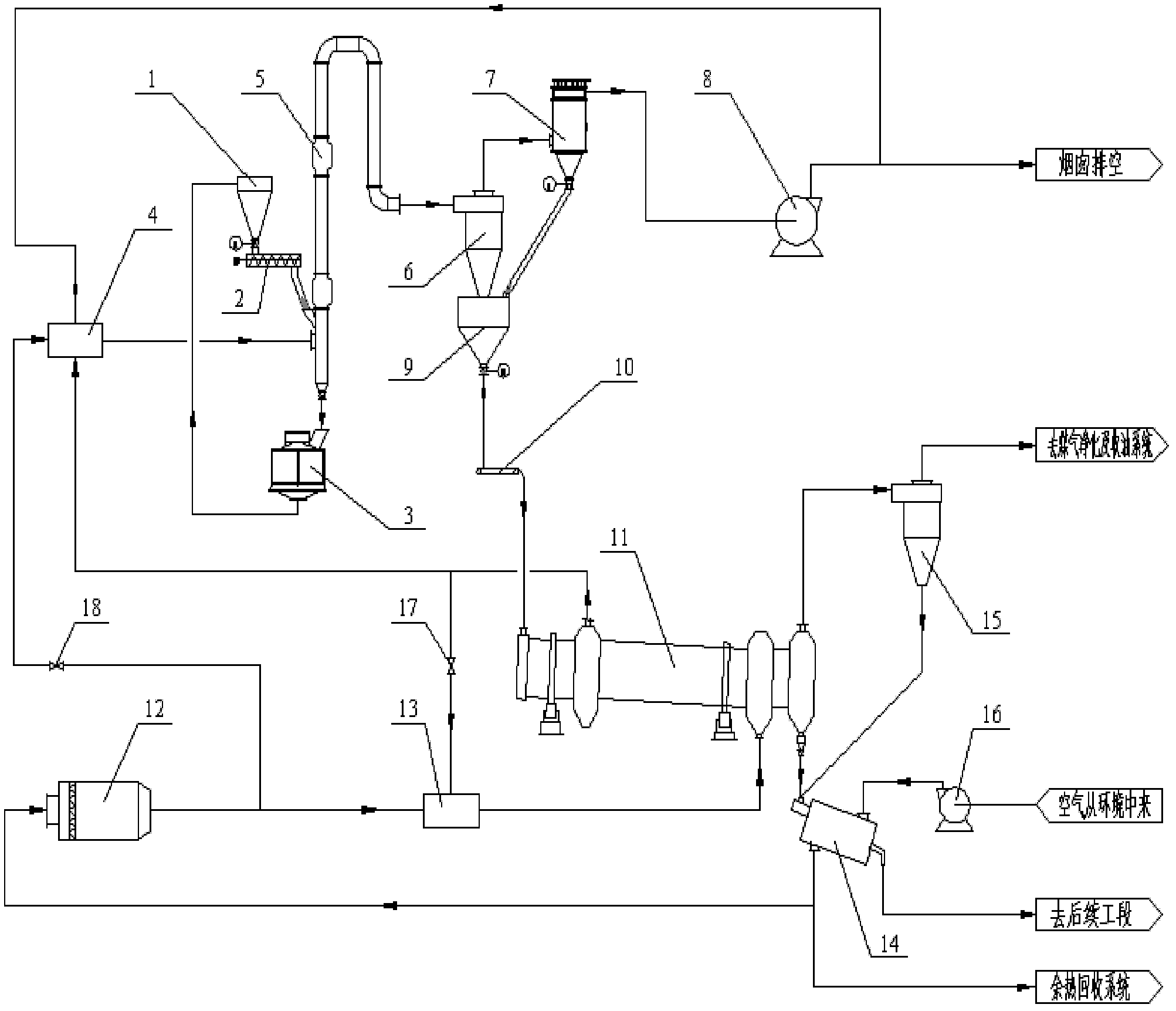

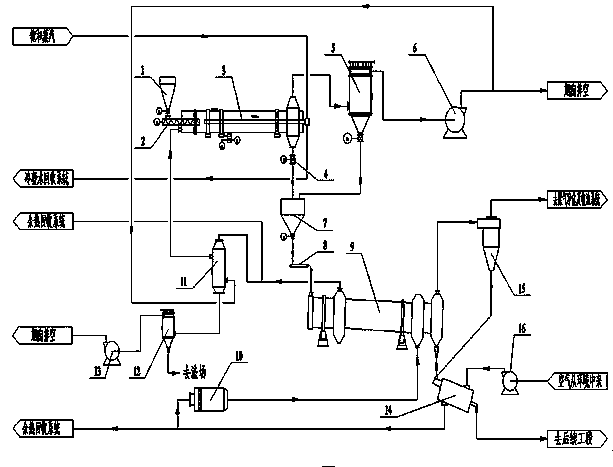

Quality-improving technique combining low-rank coal pneumatic drying with multi-tube revolving destructive distillation and system for same

ActiveCN102433142AEasy dischargeLow investment costCoke quenchingEnergy inputHigh energyCoking wastewater

The invention discloses a quality-improving technique combining a low-rank coal pneumatic drying with a multi-tube revolving destructive distillation and a system for the same, wherein the technique comprises a coal flow and a hot smoke flow, and both of the coal flow and the hot smoke flow comprise a drying process and a destructive distillation process which are connected with each other; the system comprises a gas flow drying system and a multi-tube revolving destructive distillation system which are connected with each other. The quality-improving technique combining a low-rank coal pneumatic drying with a multi-tube revolving destructive distillation and the system for the same disclosed by the invention realize a cascade efficient utilization for a high-temperature smoke, and increase the energy utilization rate of the whole system. The quality-improving technique combining a low-rank coal pneumatic drying with a multi-tube revolving destructive distillation and the system for the same disclosed by the invention have the advantages of high energy utilization rate, safe and stable system, small treatment capacity for destructive distillation gas, small treatment capacity for coking wastewater, high yield of tar, high calorific value of coal gas etc. The quality-improving technique combining a low-rank coal pneumatic drying with a multi-tube revolving destructive distillation and the system for the same disclosed by the invention also can recover chemical raw materials such as coal tar generated during a low-rank coal low-temperature destructive distillation process, and increase the comprehensive utilization rate of coal. Via the technique, a powdery or granular semicoke which is low in volatile matter, high in low caloric value and good in stability is produced by a quality-improving technique using a low-rank coal low-temperature destructive distillation. The technique is suitable for producing a civil or industrial coal gas with a medium caloric value by a quality-improving technique using a low-rank coal low-temperature destructive distillation.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

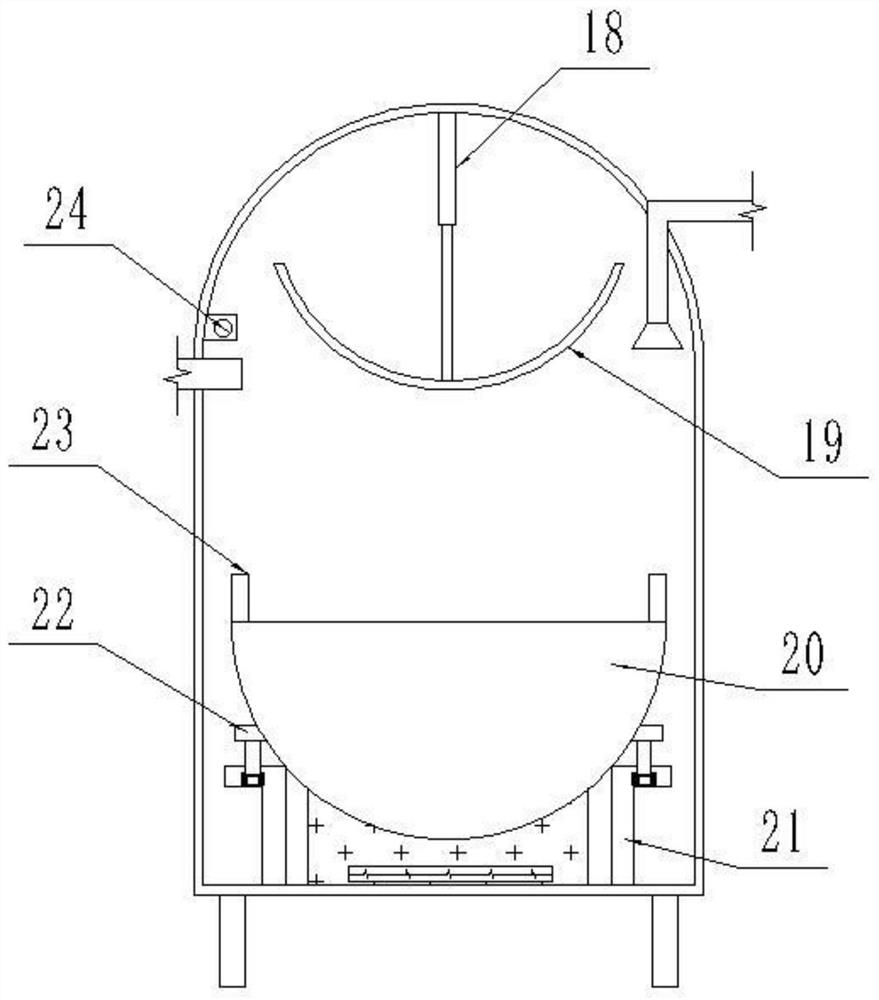

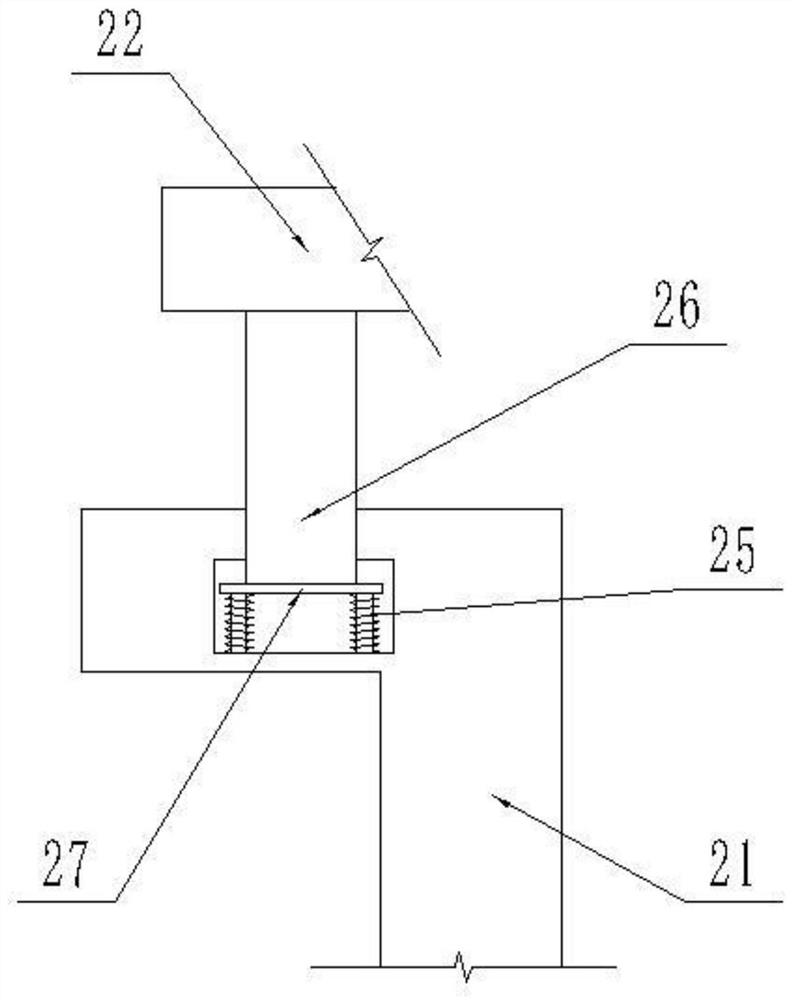

Biomass dry distillation furnace and charcoal preparation method

ActiveCN107779216AHigh recovery rateGuaranteed qualityCoke quenchingSpecial form destructive distillationCollection systemProcess engineering

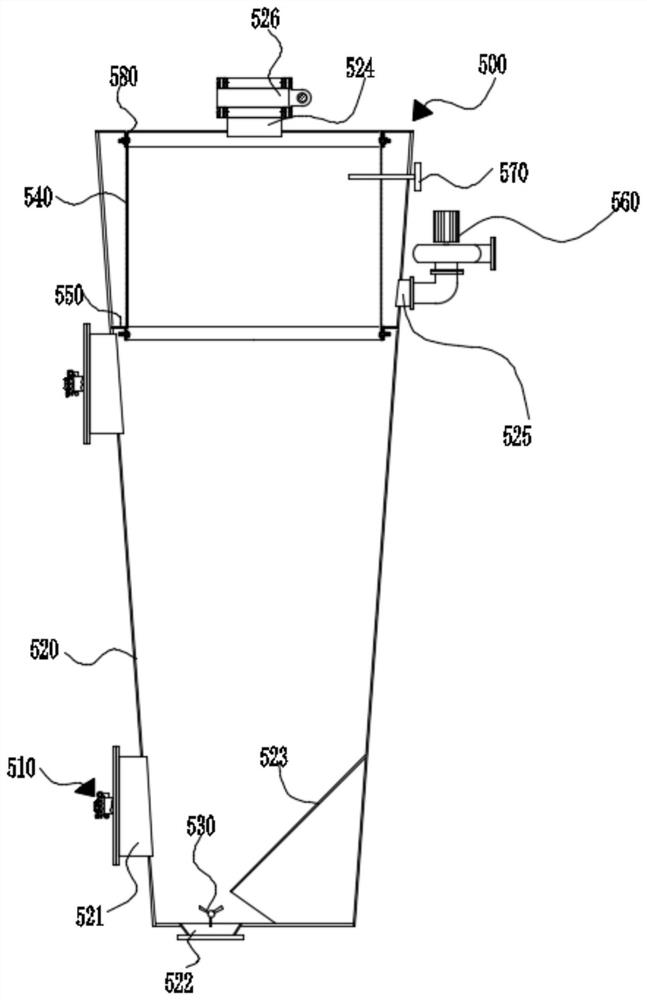

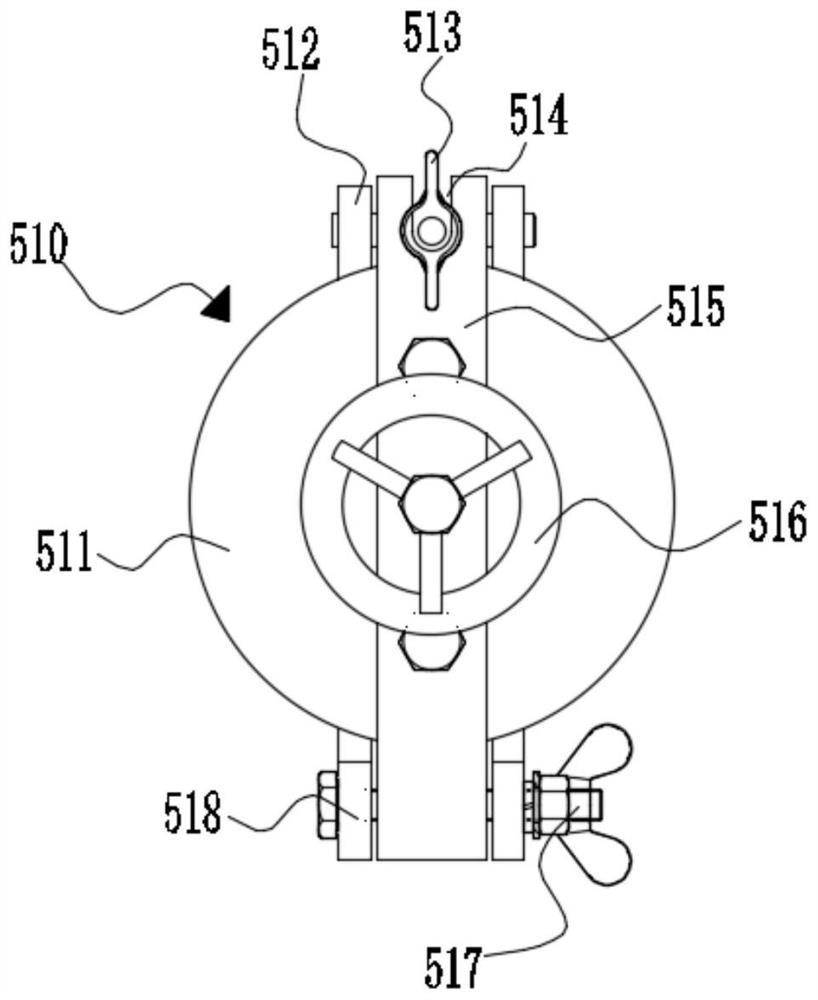

The invention relates to the field of comprehensive utilization of biomass energy and discloses a biomass dry distillation furnace and a charcoal preparation method. The biomass dry distillation furnace comprises a biomass loading system, a dry distillation system, a retorting gas collection system and a charcoal discharge system, wherein a first humidifying apparatus is arranged in the charcoal discharge system; the charcoal enters the charcoal discharge system; the first humidifying apparatus sprays a humidifying medium; the humidifying medium reacts with the charcoal to produce water gas while cooling the charcoal. According to the biomass dry distillation furnace disclosed by the invention, high-efficiency externally-heated biomass dry distillation equipment can realize batch feeding,continuous dry distillation and continuous discharging of biomass blocks, has loading and closing functions and also has retorting gas collection and maximum heat reutilization functions. Moreover, the invention further provides a high-quality charcoal preparation method.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Production method and equipment for co-production of bamboo charcoal and bamboo vinegar

PendingCN108893129AIncrease productivityHigh yieldIon-exchange process apparatusIon-exchanger regenerationSodium bicarbonateWater insoluble

The invention relates to a production method for co-production of bamboo charcoal and bamboo vinegar. The production method includes the following steps that S1, raw materials are selected; S2, moso bamboos are crushed, wherein the moso bamboos with the branches and leaves are crushed into 3-5 mm blocks according to the technological requirement, soaking with a pretreatment solution is conducted for 1-2 h, drainage is conducted, and then the objects are pre-dried at 60-70 DEG C until the water content is 20-25 % and sent to a pre-heating mechanism through a feeding mechanism, the pretreatmentsolution is prepared from, by weight, 3-8 % of water insoluble dextran, 10-15% of sodium hydrogen carbonate, 2-5% of aminophylline and the balance deionized water; S3, pre-heating is conduced; S4, pyrolysis is conducted; S5, carbonization is conducted; S6, bamboo vinegar purification is conducted, wherein bamboo vinegar obtained in the step 3 and bamboo vinegar obtained in the step 4 are mixed, anadsorption treatment agent is added in the mixture, then the mixture is stirred evenly, treated for 0.5-1 h and fully filtered, and the finished product of bamboo vinegar is obtained, the adsorptiontreatment agent refers to modified sepiolite powder. The production efficiency is high, the product yield is high, the degree of automation is high, and through organic coordination of the various mechanisms, the requirement of industrialized co-production of bamboo charcoal and high-quality bamboo vinegar can be met.

Owner:宁波甬文新能源装备研发有限公司

Municipal sludge destructive distillation carbonation test system

InactiveCN106145592AAvoid explosionAvoid enteringSpecific water treatment objectivesSludge treatment by pyrolysisInsulation layerSludge

The invention relates to a municipal sludge destructive distillation carbonation test system and belongs to the technical field environment engineering. The test system comprises a destructive distillation reaction device, a gas-liquid collecting device, a gas treatment device and a control device. The municipal sludge destructive distillation carbonation test system has the advantages that a vacuum pump and one-way valve used by the destructive distillation reaction device vacuumize a reaction kettle before the destructive distillation of sludge, the risk of explosion is avoided, and system safety is guaranteed; each of the reaction kettle and a reaction kettle cover adopts a sandwich structure, a thermal-insulation layer is arranged in each sandwich layer, the temperature in the reaction kettle is guaranteed, and heat loss is lowered; a condenser and a cooling-water machine effectively guarantee the condensation separation effect of destructive distillation products; a gas burner guarantees that tail gas can meet standards; the destructive distillation products can be sampled and analyzed at any time, the temperature of each link can be monitored in real time, and destructive distillation parameters can be optimized conveniently; system parameters can be set on the control device, the control device treats data, and system efficiency is increased greatly.

Owner:JIANGSU ZHONGYI ECOLOGICAL SOIL INST +1

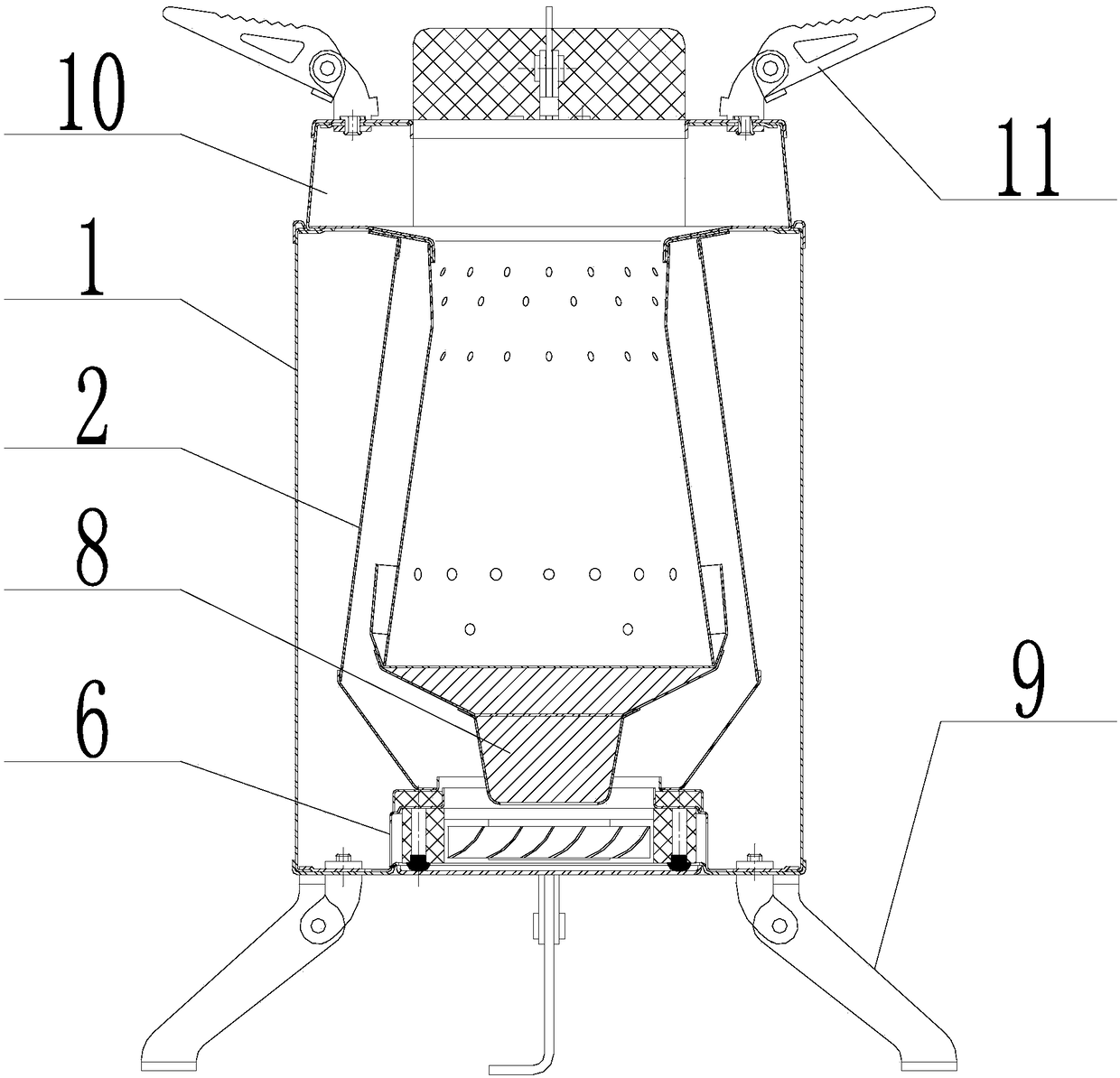

Energy-saving and environment-friendly firewood burning furnace

ActiveCN106247410APromote gasificationImprove stabilityDomestic stoves or rangesLighting and heating apparatusFirewoodProcess engineering

The invention discloses an energy-saving and environment-friendly firewood burning furnace. The energy-saving and environment-friendly firewood burning furnace comprises a furnace shell and a hearth, and is characterized in that the furnace shell is of a closed cylindrical structure arranged outside the hearth in a sleeving manner, the hearth comprises a burning barrel and an outer barrel arranged on the outer side of the burning barrel in a sleeving manner, a gap is formed between the outer wall of the burning barrel and the outer barrel to form an airflow cavity, an air supply assembly communicating with the airflow cavity is arranged at the bottom of the outer barrel, and the burning barrel and the outer barrel are of a conical structure with the small upper portion and the large lower portion. According to the energy-saving and environment-friendly firewood burning furnace, the whole hearth is set to be of the conical structure, the air supply efficiency is improved, higher airflow can be obtained through burning, the air and fuel gas mixing ratio needed for premixed burning is achieved, pyrolysis of combustible molecules and better gasification of carbon particles are achieved, combustibles are completely burned to obtain high-heat-value fuel gas, accordingly, the higher hearth temperature and the continuous and stable furnace opening high temperature are obtained, the burning furnace opening temperature is continuously stabilized to be above 1,050 DEG C, energy consumption is low, and output is high.

Owner:成都市沛源五金制品有限公司

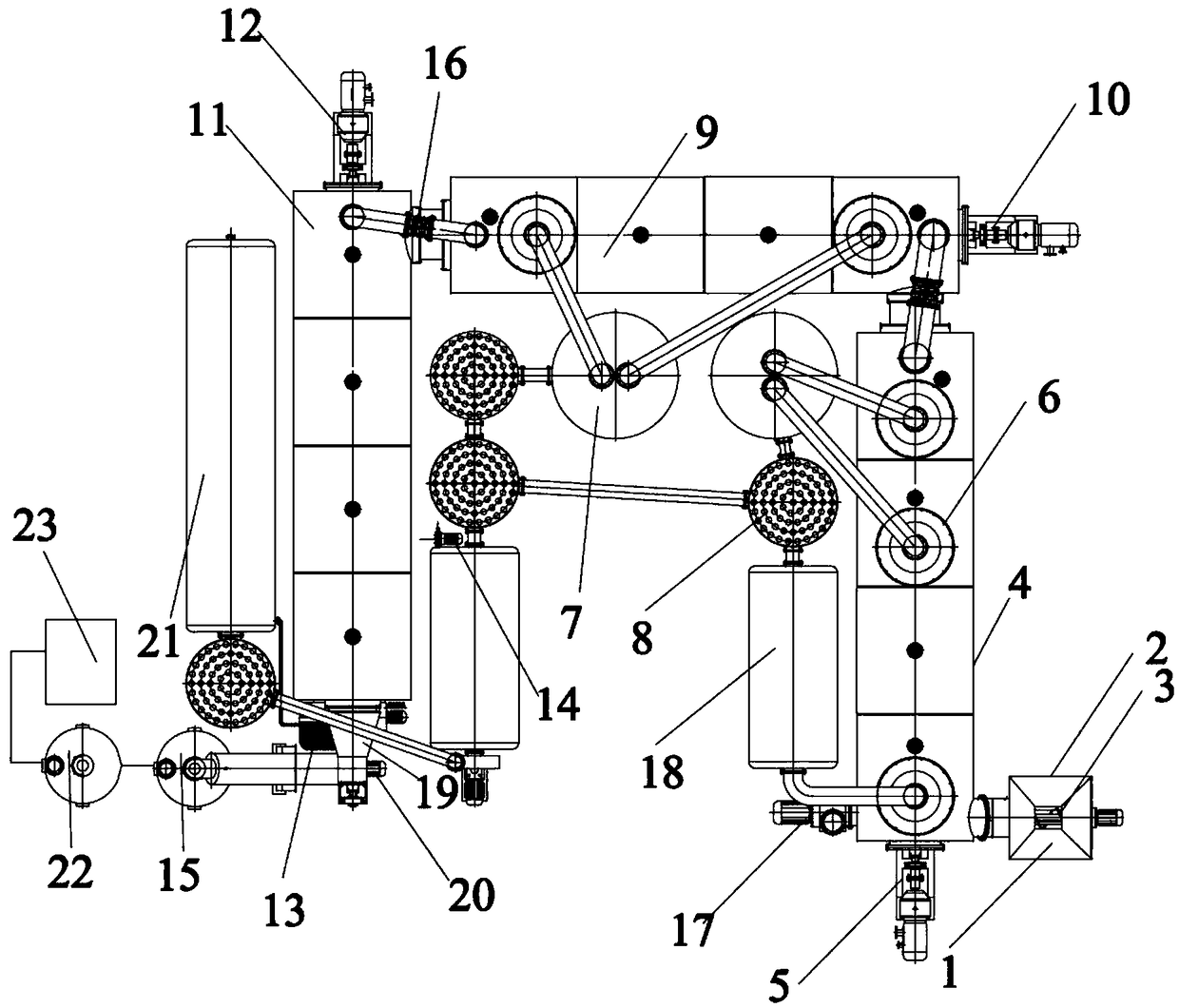

Solid fuel spiral dry distillation machine

ActiveCN111748364ARaise the fuel heating surfaceGood dry distillation effectBiofuelsIndirect heating destructive distillationHot blastProcess engineering

Owner:安徽林农时代科技有限公司

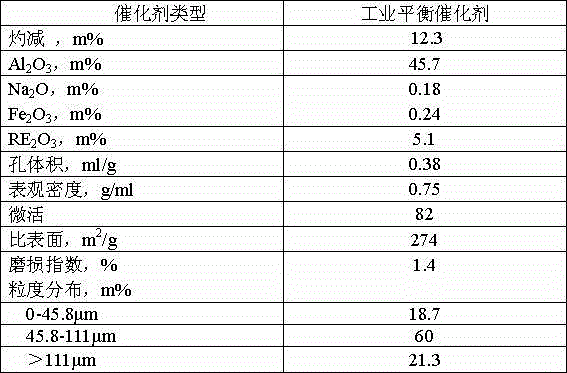

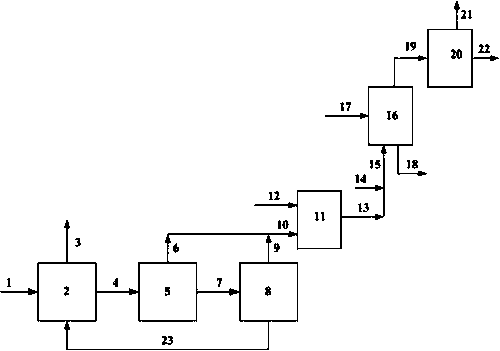

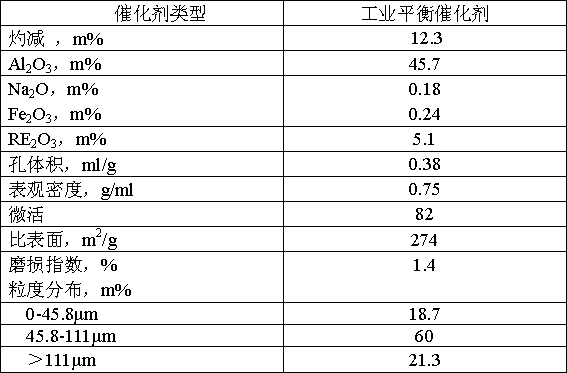

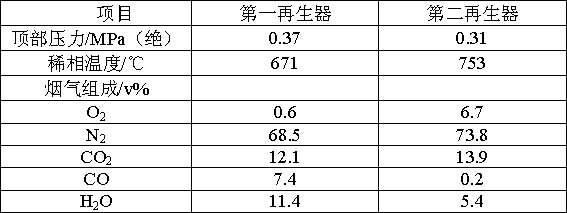

Coal carbonization and coal catalytic cracking combined process

ActiveCN105647551AImprove retort effectDirect heating destructive distillationTreatment with plural serial stages onlyPtru catalystHeat carrier

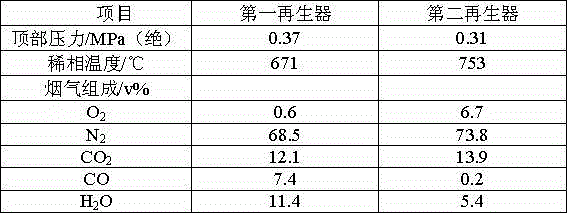

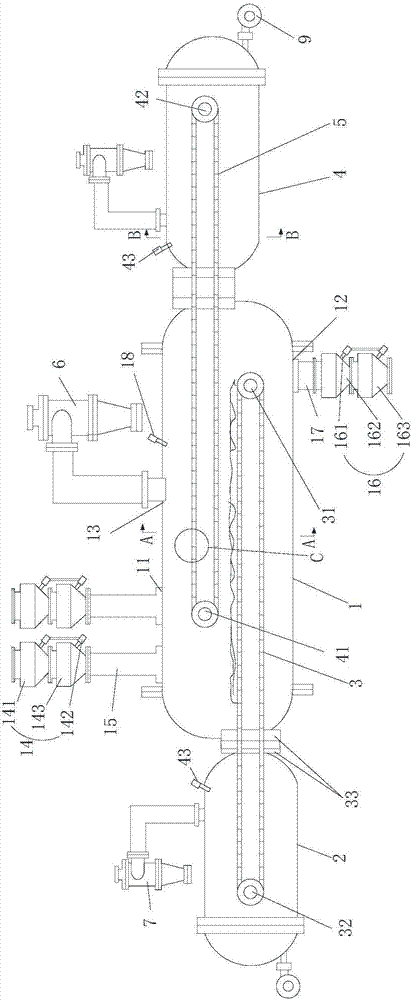

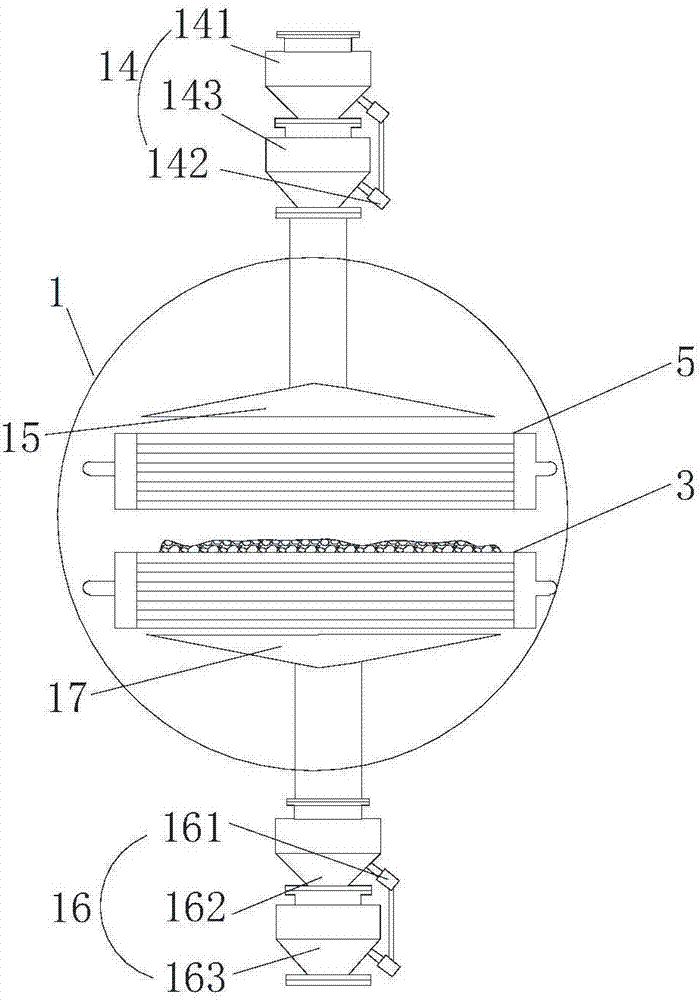

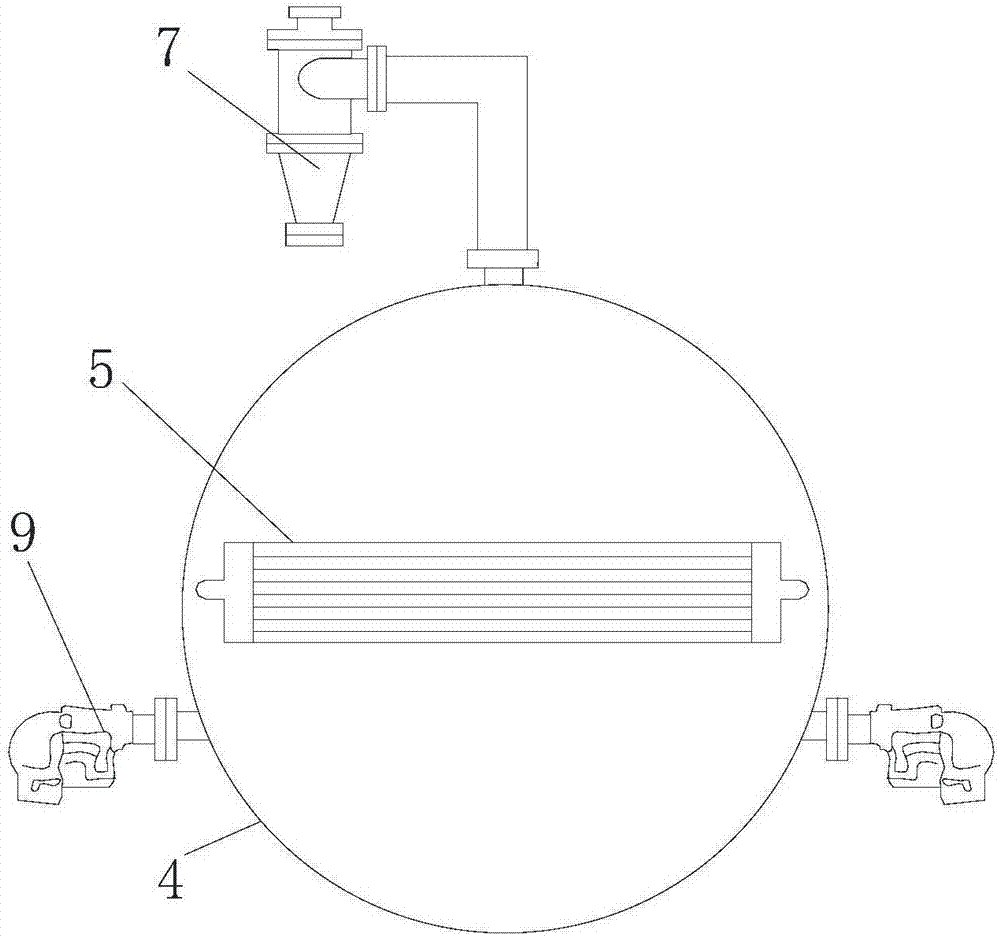

The invention discloses a c carbonization and coal catalytic cracking combined process. catalyst first regenerator flue gas and catalyst second regenerator flue gas are mixed and then burn together with burning supporting gas, the temperature of burned flue gas is controlled at 600-1200DEG C, preferably 800-1000DEG C, a proper amount of water is injected into the burned flue gas to serve as a heat carrier to perform low temperature carbonization on a carbonization raw material, thus generating coal gas, semicoke and coal tar, and the volume content of water vapor converted from the injected water in the heat carrier is 1-50v%. The method can improve the yield of coal tar.

Owner:CHINA PETROLEUM & CHEM CORP +1

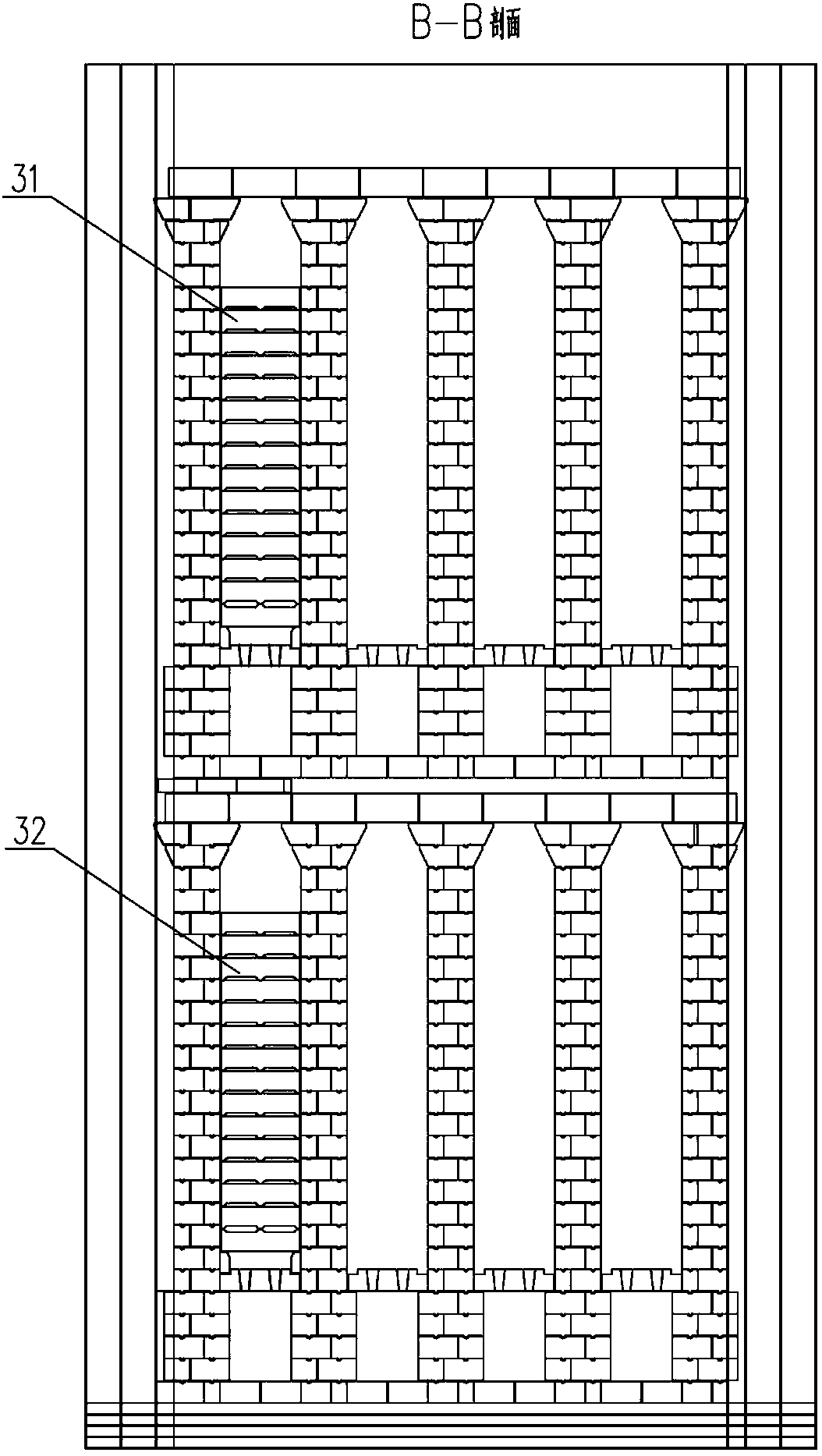

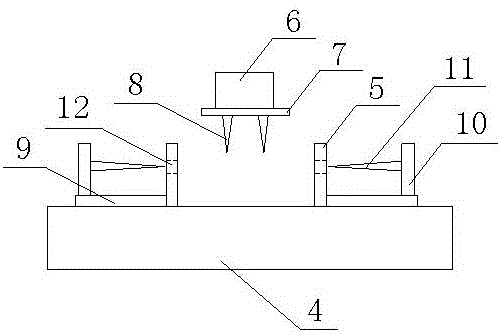

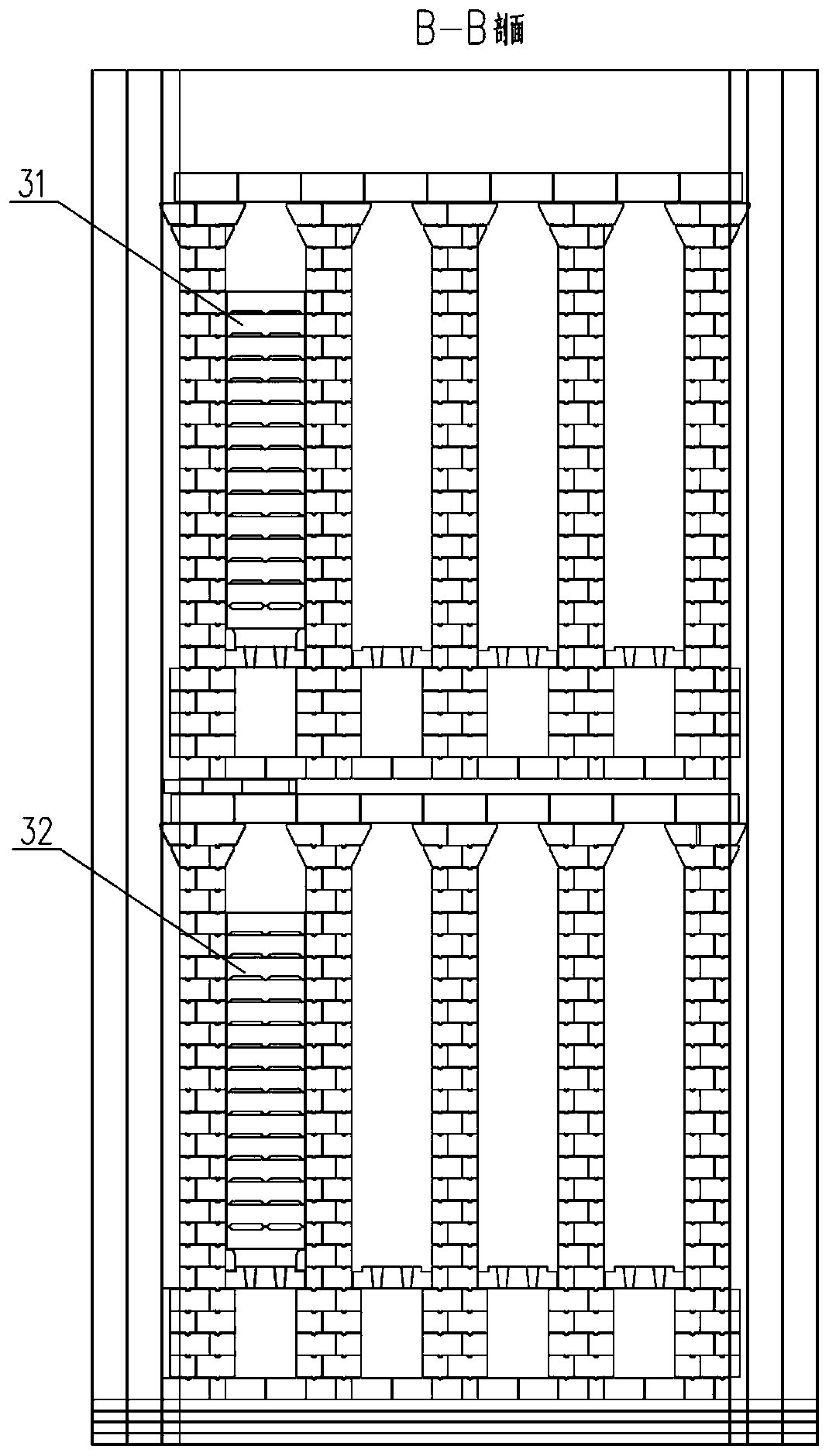

Heat storage type heating separating device

InactiveCN107099308AAvoid driftImprove the effectHorizontal chamber coke ovensIndirect heating destructive distillationDry distillationEngineering

The invention provides a heat storage type heating separating device, and relates to the technical field of dry distillation equipment. The heat storage type heating separating device comprises a dry distillation device, a first heating device, a first heat storage device and a first driving device. Feed inlets, a discharge outlet and a gas outlet are formed in the dry distillation device; the first heating device is positioned on a side of the dry distillation device; the first heat storage device is of a closed ring structure, one end of the first heat storage device is positioned in the first heating device, the other end of the first heat storage device is positioned in the dry distillation device, the first driving device is used for driving the first heat storage device to carry out circulating rotation, and a combined sealing device is arranged between the first heating device and the first heat storage device; the feed inlets are formed in the left end of the top of the dry distillation device and are particularly formed in positions above the first heat storage device; the discharge outlet is formed in the end, which is far away from the feed inlets, of the bottom of the dry distillation device and is particularly formed in the rear of the first heat storage device. Compared with the prior art, the heat storage type heating separating device has the advantages that the heat storage type heating separating device is safe and stabile in running, simple in structure and high in dry distillation efficiency, and obtained dry distillation gas phases are good in quality.

Owner:王萍

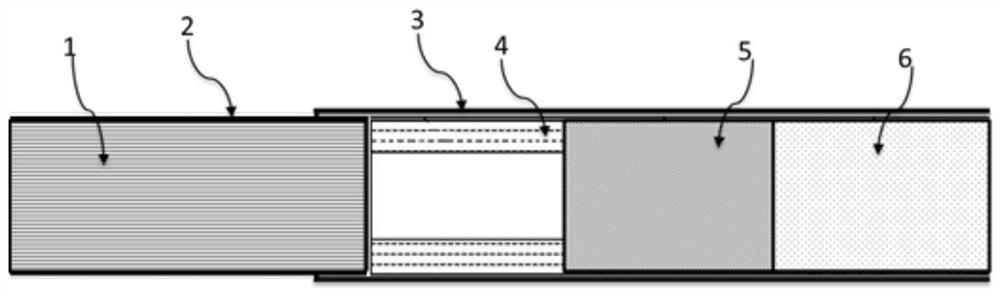

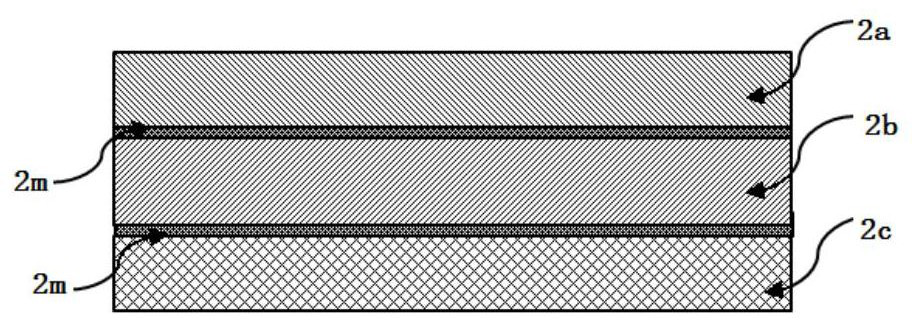

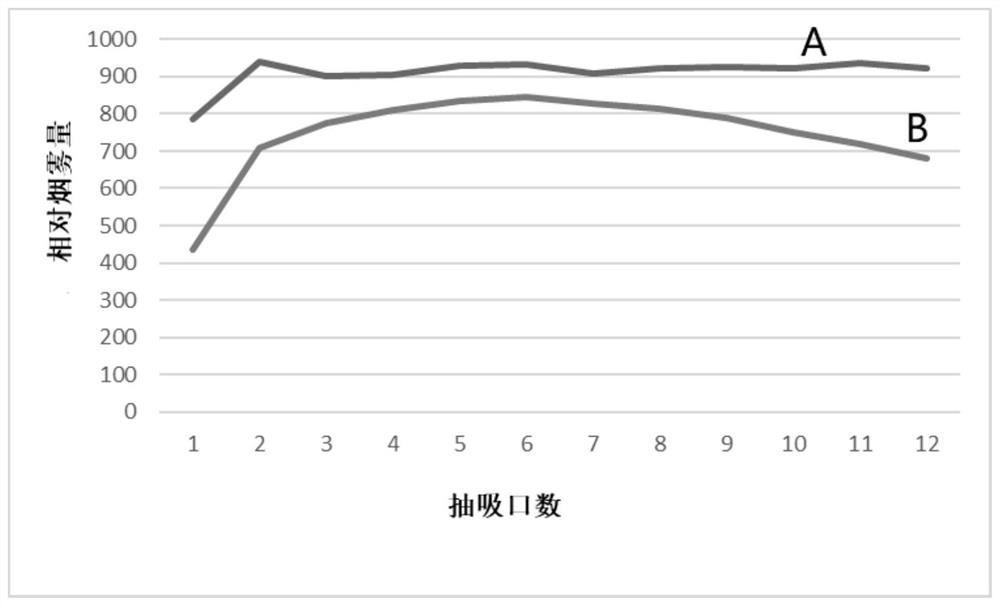

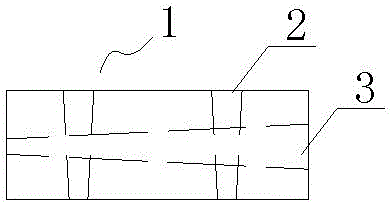

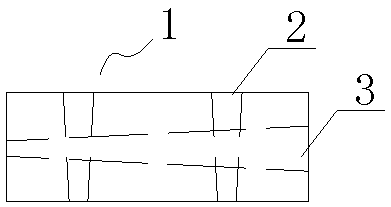

Method for improving smoking stability and heat utilization rate of heated cigarette

PendingCN113679095AImprove uniformityGood suction stabilityCigar manufactureChemistryManufacturing engineering

The invention belongs to the field of novel heating cigarettes, and particularly relates to a method for improving the smoking stability and the heat utilization rate of a heated cigarette. According to the method, the cigarette is prepared through the following operation, the cigarette comprises a fuming medium section, the fuming medium section is prepared by wrapping a fuming medium rod (1) with composite cigarette paper (2), and the composite cigarette paper (2) is prepared through the following steps that a first cigarette paper layer (2a), a graphite paper layer (2b) and a coating layer (2c) are bonded through an adhesive layer (2m) to form the composite cigarette paper (2), and the coating layer (2c) is in contact with the fuming medium rod (1). According to the invention, the uniformity of substance release in the smoking process is effectively improved, the smoking stability is better, and the amount of smoke which can be smoked by 12 mouths is not obviously reduced.

Owner:CHINA TOBACCO YUNNAN IND +1

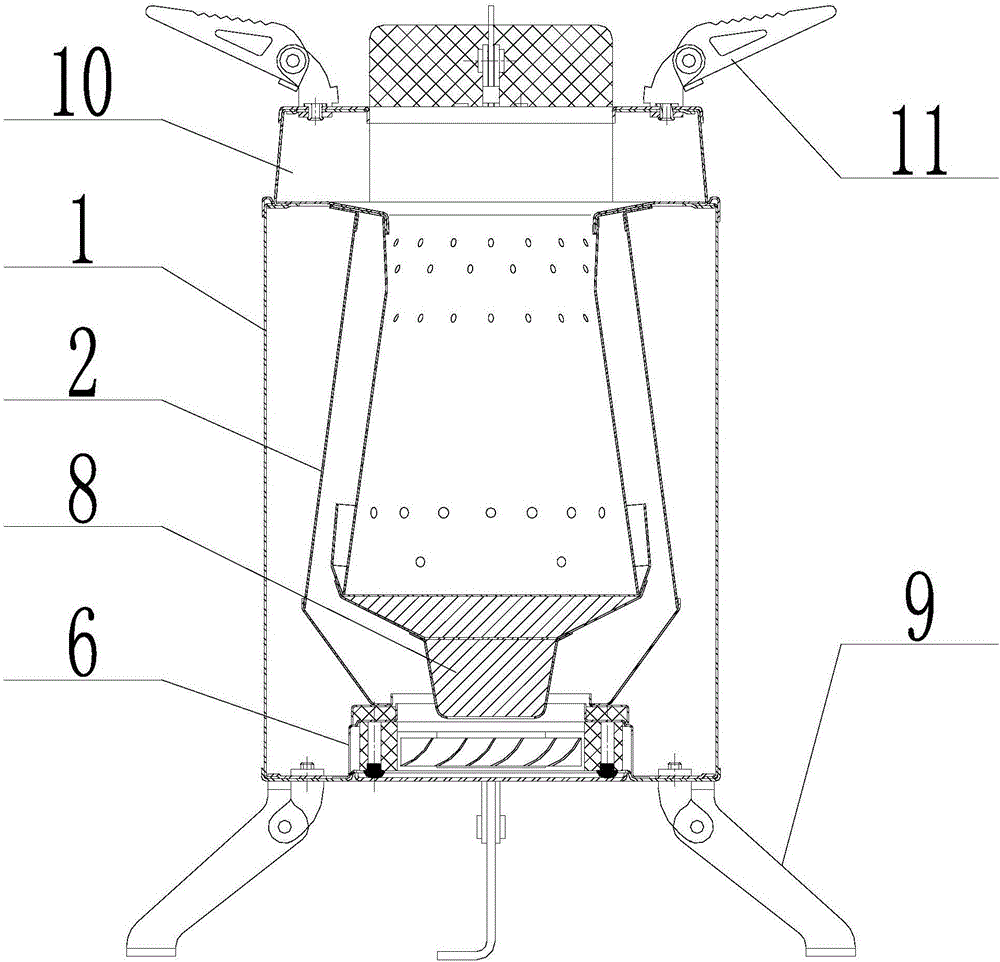

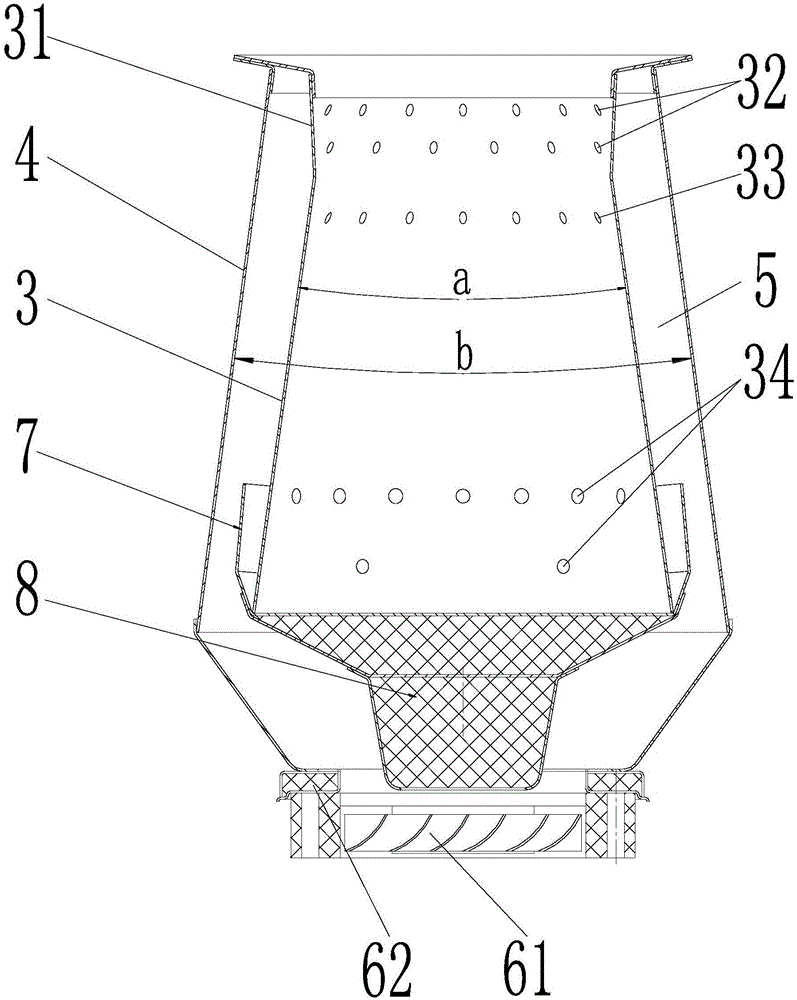

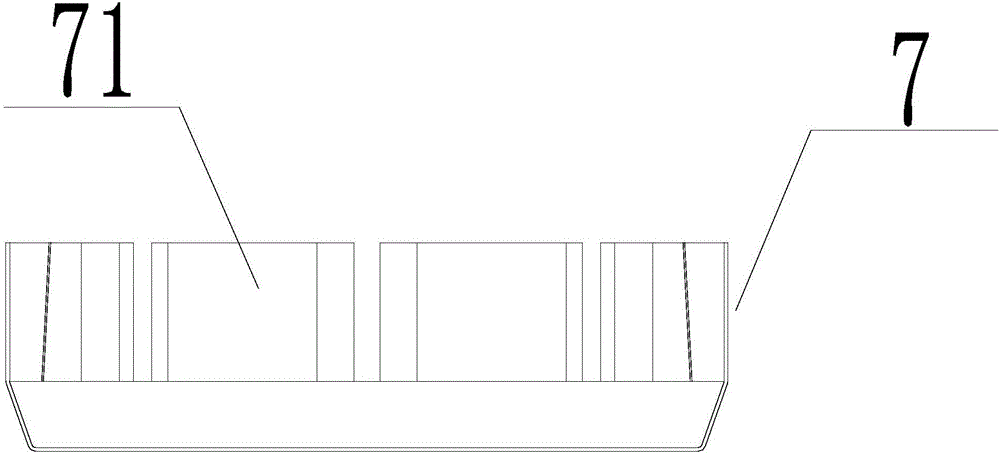

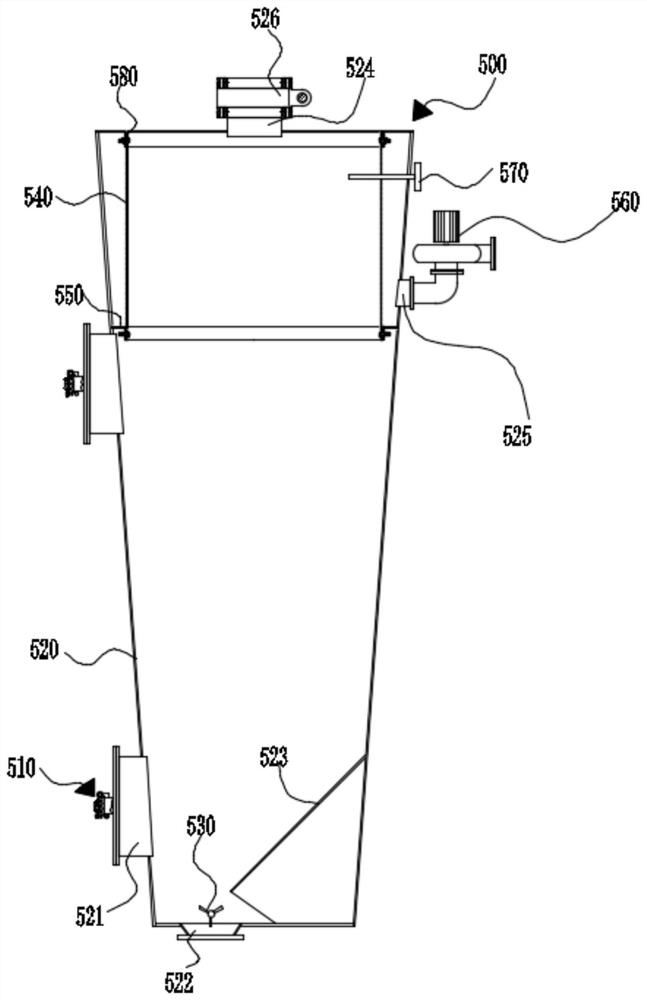

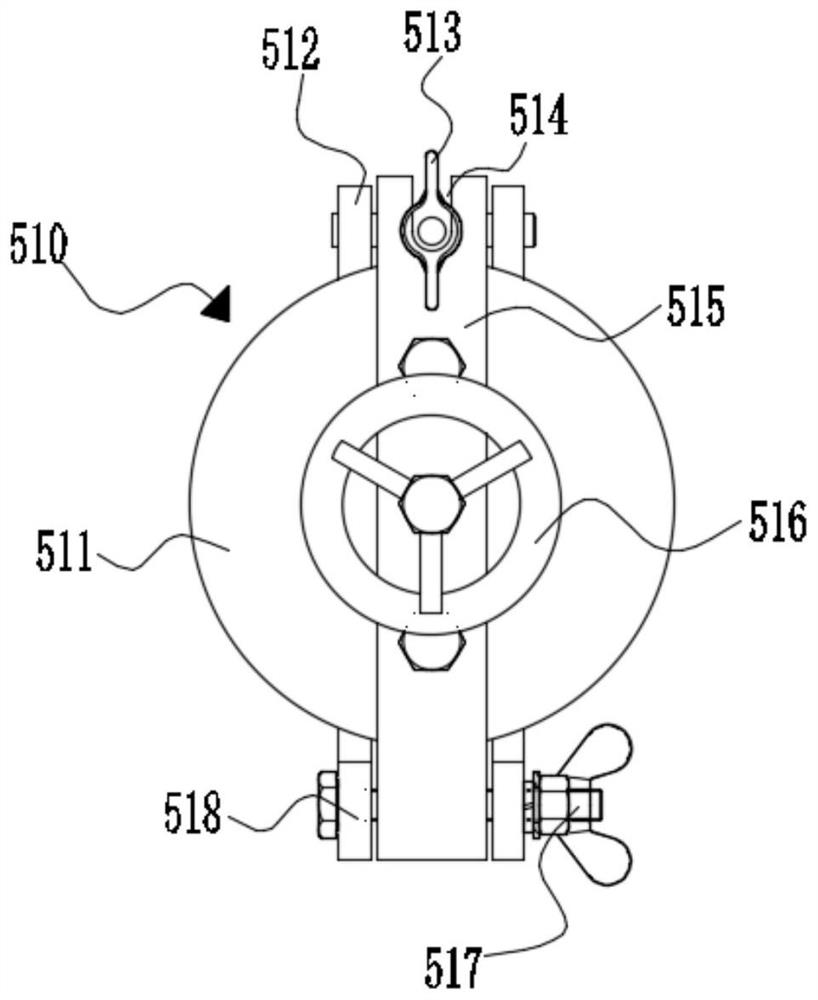

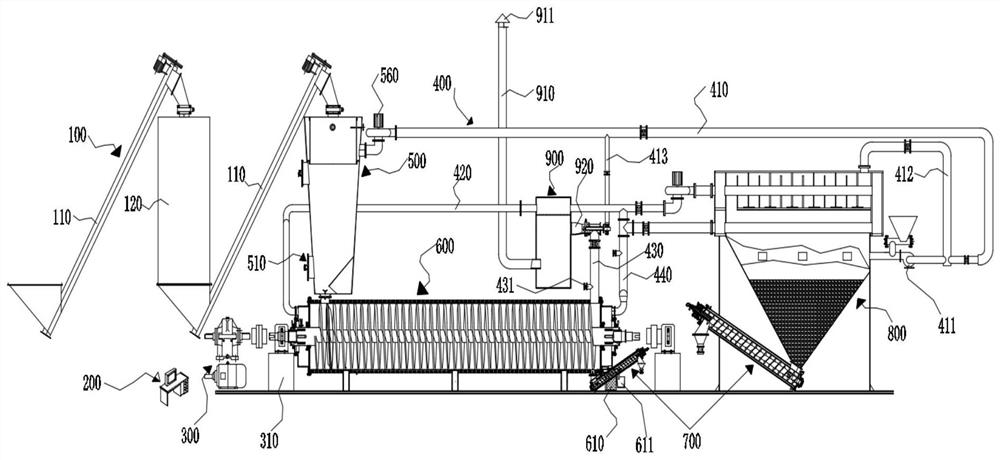

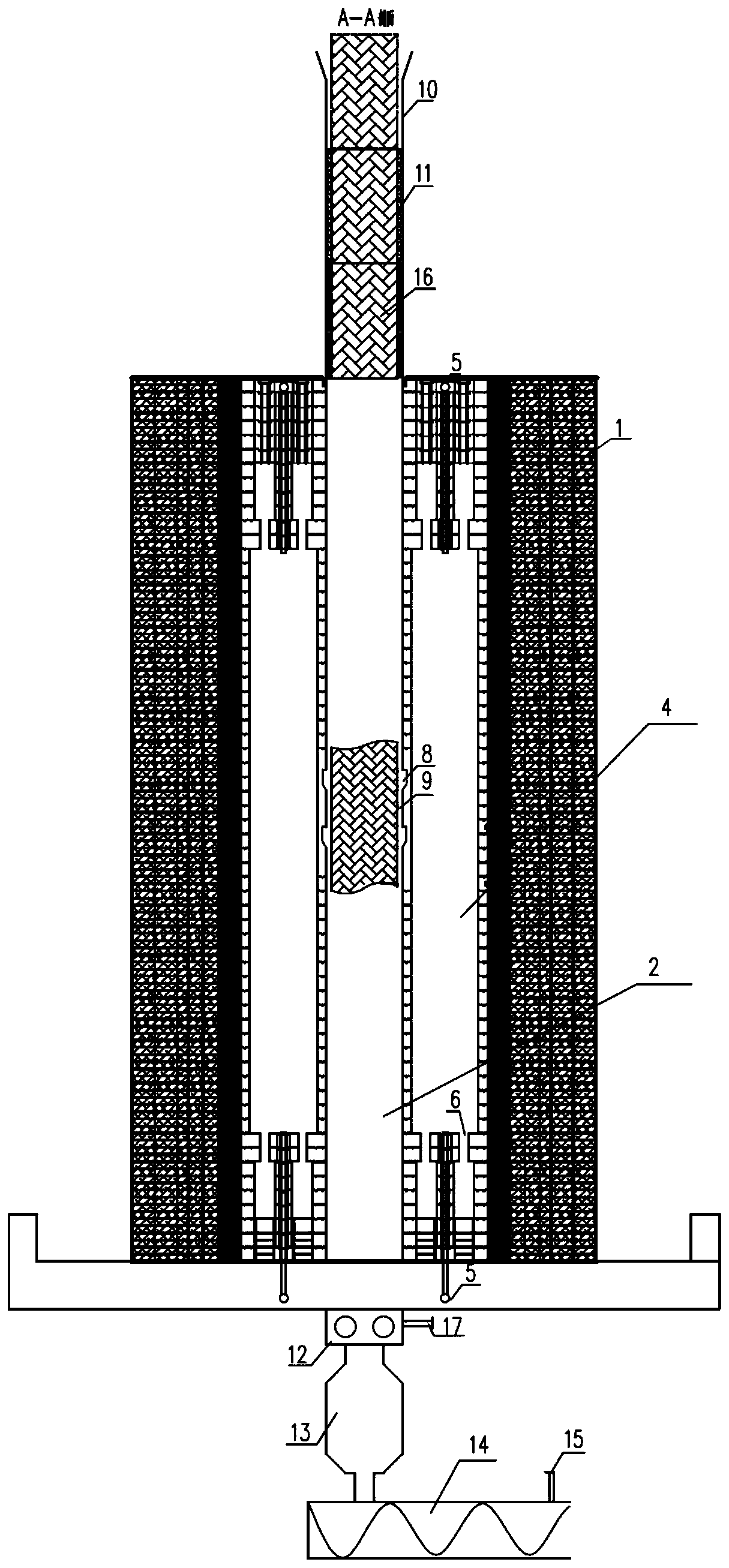

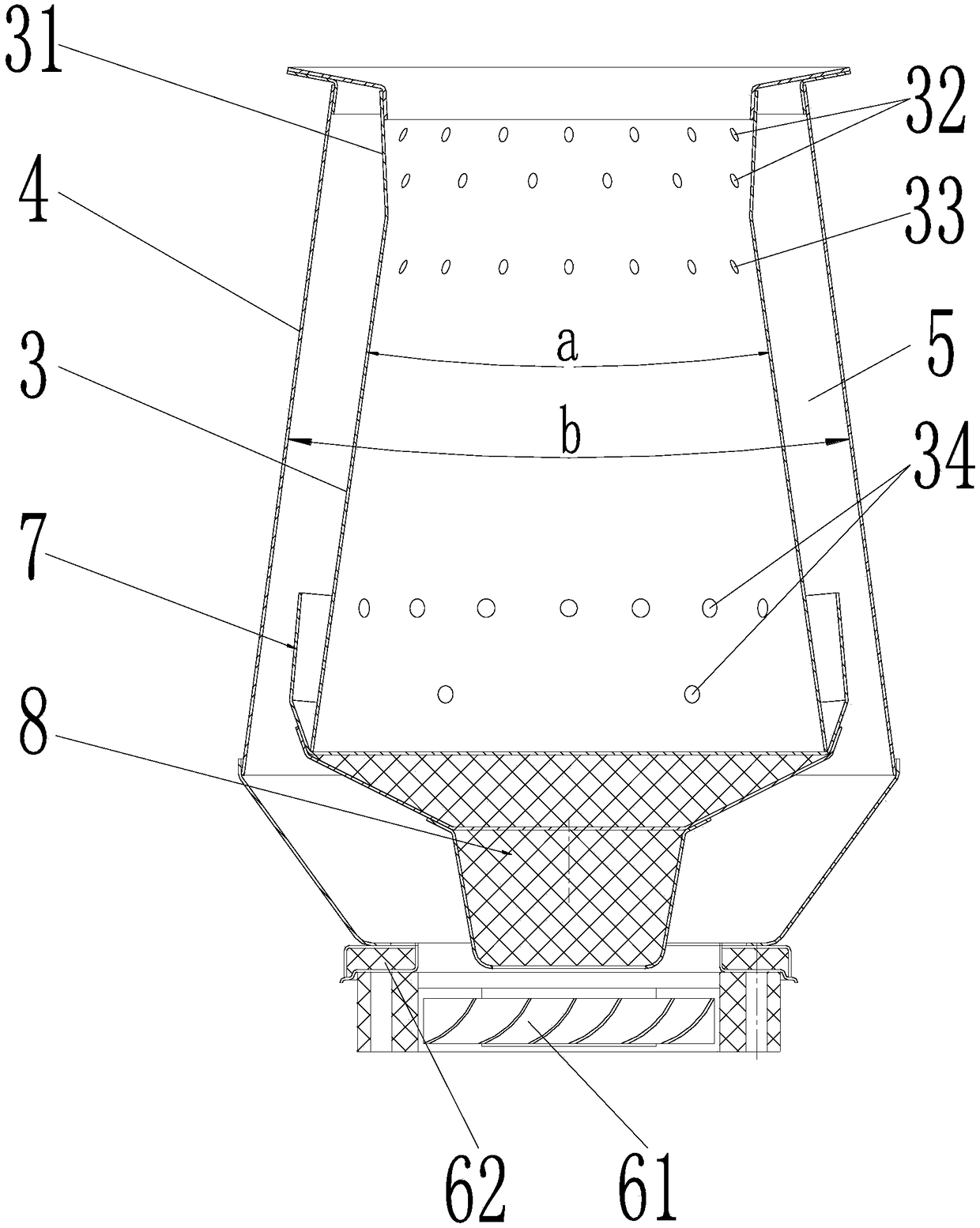

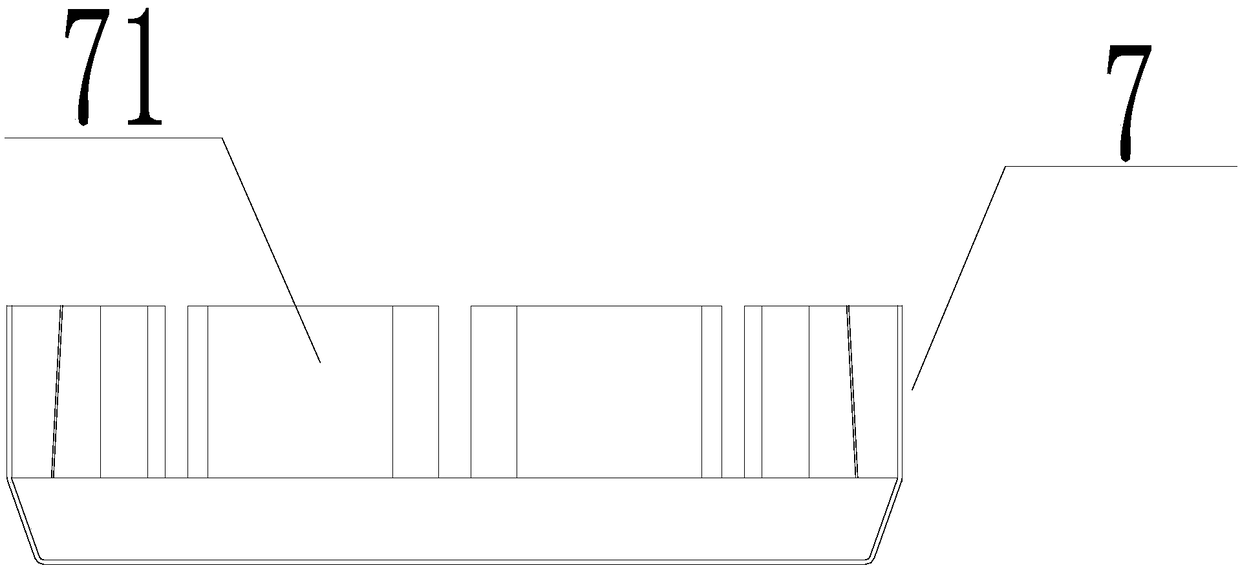

A solid fuel spiral dry distillation machine

ActiveCN111748364BIncrease the heating surfaceImprove retort effectBiofuelsIndirect heating destructive distillationHot air ovenSolid fuel

The purpose of the present invention is to provide a solid fuel spiral dry distillation machine, including feeding equipment and dry distillation equipment, and also includes a fuel filter, a temperature discharge charcoal device and a curved hot blast stove, the fuel filter includes a barrel, the The fuel inlet pipe at the top of the barrel is connected to the discharge end of the feeding device, the tapered discharge pipe at the bottom of the barrel is connected to the inlet of the carbonization equipment, and the side of the barrel is equipped with an air outlet The retort equipment includes a retort barrel, two rotary seals and a first hollow spiral barrel, the two rotary seals are arranged on both sides of the retort barrel, and the first hollow spiral barrel includes a first hollow spiral piece and a hot air cylinder sealed and welded on both sides of the first hollow spiral piece, the first hollow spiral cylinder is coaxially rotated and installed in the retort cylinder, and the hot air cylinders at both ends of the first hollow spiral cylinder extend to the outside of the rotary seal, the A flow hole communicating with the rotary seal is opened on the hot air cylinder.

Owner:安徽林农时代科技有限公司

Fluidized bed low-temperature destructive distillation system and low-temperature destructive distillation method of low-rank coal

InactiveCN103160299BExtended stayHigh solid contentDirect heating destructive distillationSpecial form destructive distillationPartial hydrogenationRetention time

The invention provides a fluidized bed low-temperature destructive distillation system and a low-temperature destructive distillation method of low-rank coal. According to the method, a mixed gas of hot coal gas produced by a gasification furnace and circulation cold coal gas is adopted as a hot carrier and a fluidizing gas of a destructive distillation reaction. A hydrogen atmosphere of coal gas can provide a partial hydrogenation effect, such that obtained tar has the advantages of high light component content, good quality, high thermal efficiency, and high yield. Also, with the method, a two-stage low-temperature destructive distillation reactor is adopted, such that the retention time of solid particles in the reactor is increased, destructive distillation effect is improved, high solid content in the bed can be maintained, and operation stability can be maintained. The invention also provides a low-temperature destructive distillation reactor. The low-temperature destructive distillation reactor is the two-stage low-temperature destructive distillation reactor, such that the retention time of solid particles in the reactor is increased, and destructive distillation effect is improved. With the two-stage low-temperature destructive distillation reactor, high solid content in the bed can be maintained, and operation stability can be maintained.

Owner:CHINA COAL ENERGY HEILONGJIANG COAL CHEM +1

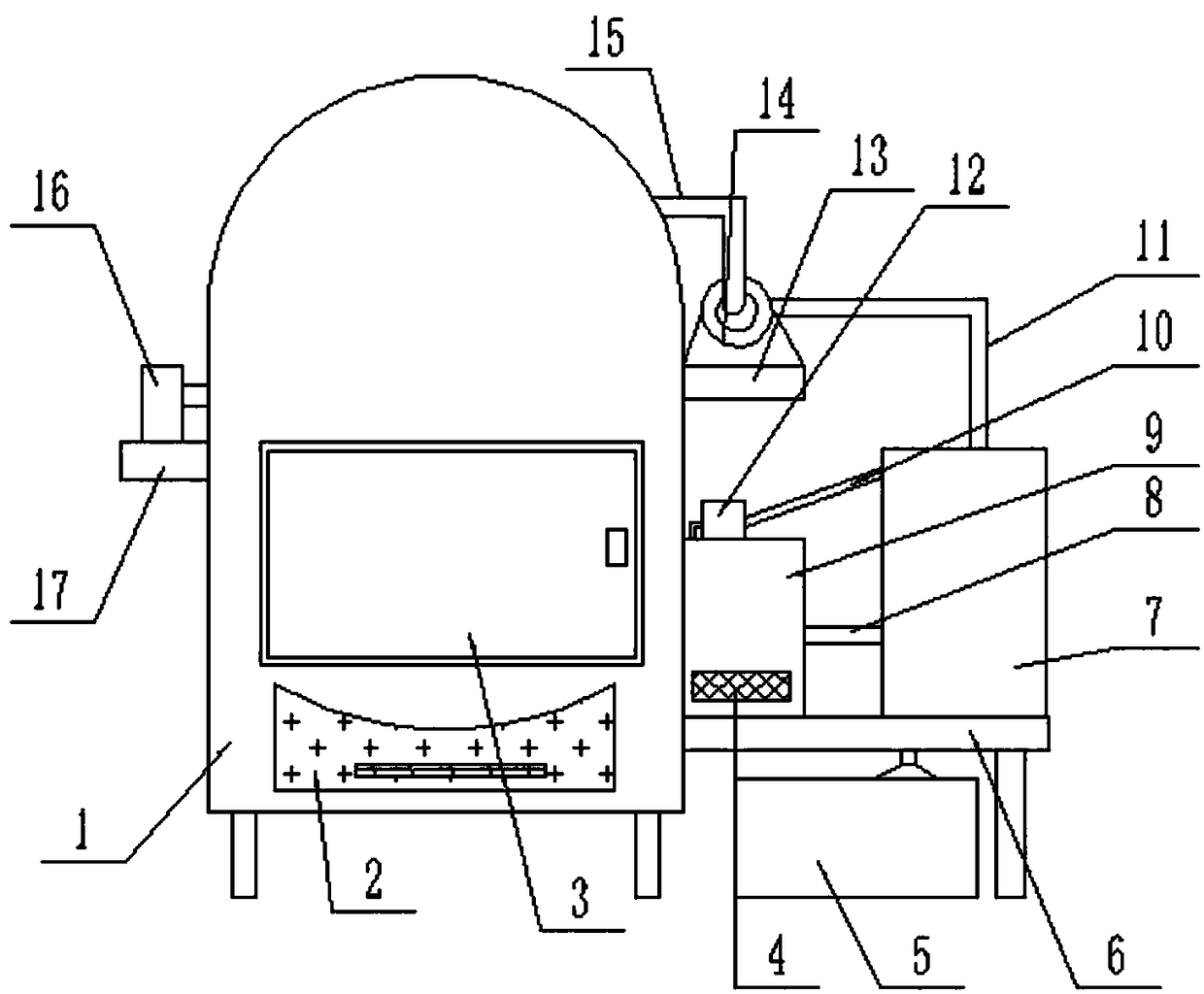

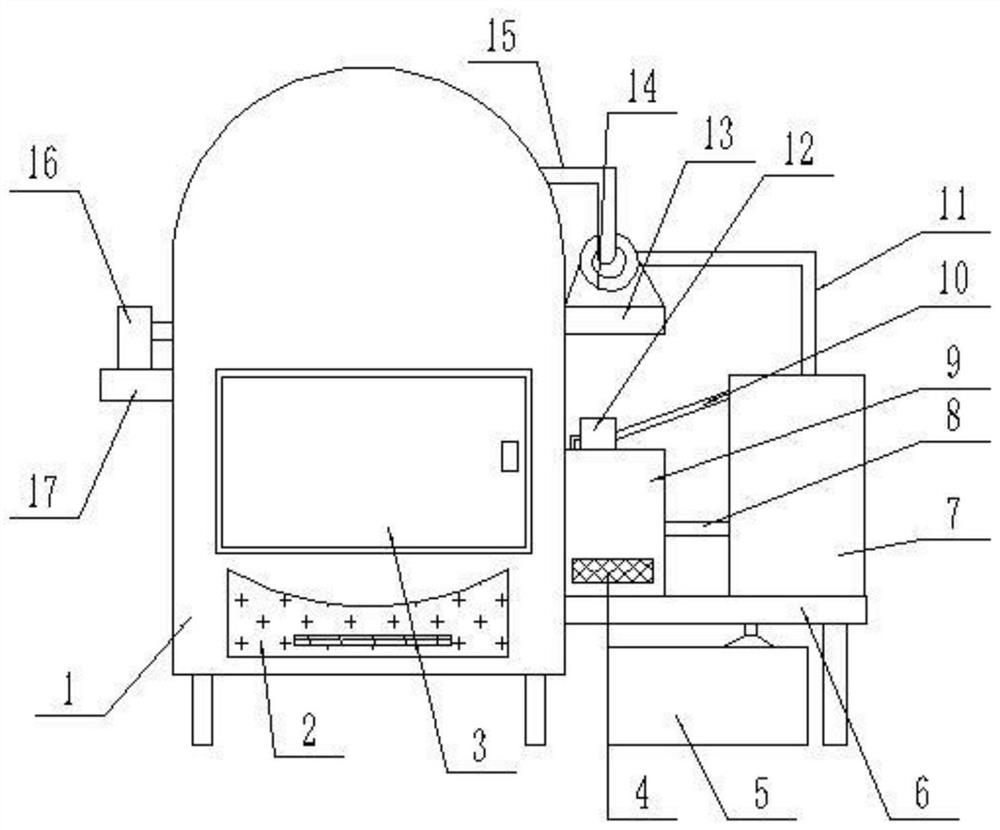

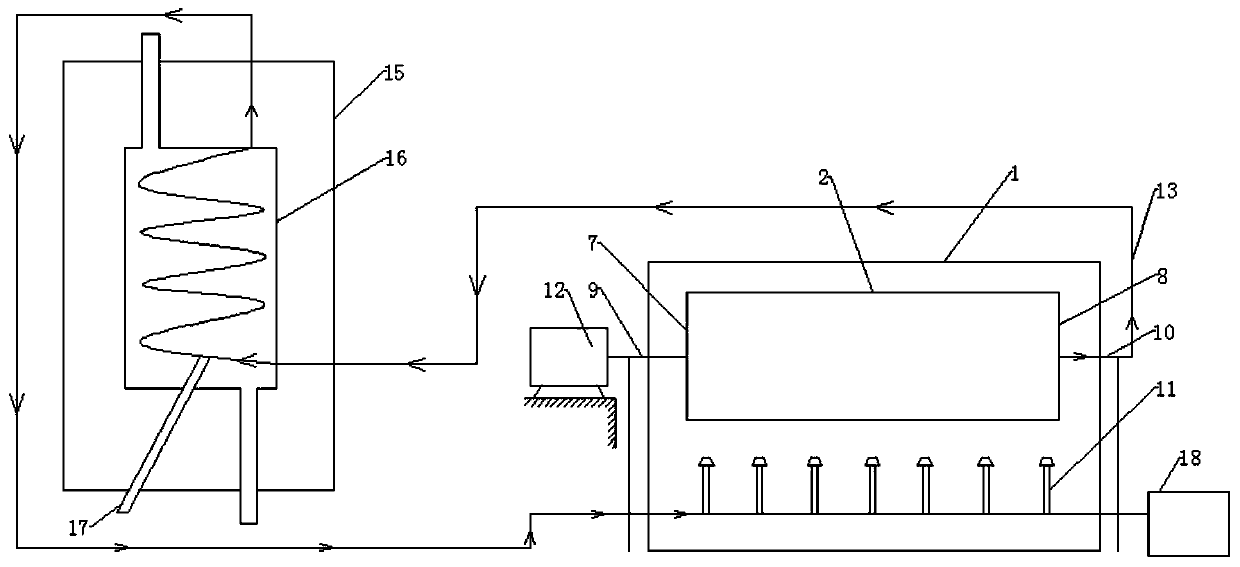

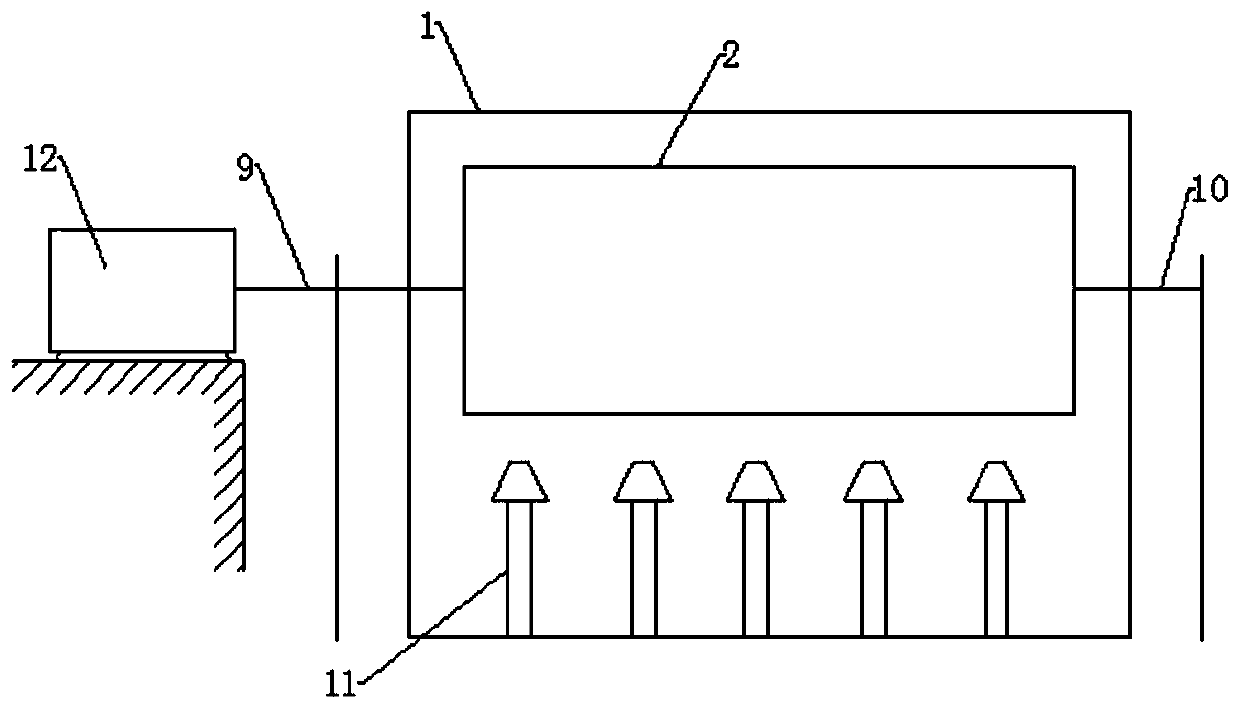

Efficient carbonizing treatment device for agricultural straw waste recycling

ActiveCN109135782APlace stableSave human effortBiofuelsOven incrustations prevention/removalEngineeringWater cooling

The invention belongs to the technical field of agricultural straw recycling and particularly discloses an efficient carbonizing treatment device for agricultural straw waste recycling. Aiming at problems of high labor force, low efficiency and poor environmental friendliness of a straw carbonizing treatment device, a scheme is put forward and includes that the efficient carbonizing treatment device comprises a tank, the outer wall of one side of the tank is provided with a heating port, a heater is arranged on the inner wall of the heating port, a supporting seat is welded to the outer wall of one side of the tank, supporting legs are welded to two corners of the outer wall of one side of the supporting seat and two corners of the bottom outer wall of the tank respectively, and a supporting table is welded to the outer wall of one side of the tank. Manpower saving is realized by mechanical straw compacting; by mounting of a vacuum pump, straw can be isolated from air to the great extent to improve dry distillation effects; by means of water cooling, a gas and steam mixture is cooled and separated into gas, liquid and dust in gas, and environmental pollution caused by direct emission of the mixture can be effectively avoided.

Owner:山西亚创环力农业科技产业股份有限公司

A combined process of coal dry distillation and coal catalytic cracking

ActiveCN105647551BImprove retort effectDirect heating destructive distillationTreatment with plural serial stages onlyHeat carrierWater vapor

The invention discloses a c carbonization and coal catalytic cracking combined process. catalyst first regenerator flue gas and catalyst second regenerator flue gas are mixed and then burn together with burning supporting gas, the temperature of burned flue gas is controlled at 600-1200DEG C, preferably 800-1000DEG C, a proper amount of water is injected into the burned flue gas to serve as a heat carrier to perform low temperature carbonization on a carbonization raw material, thus generating coal gas, semicoke and coal tar, and the volume content of water vapor converted from the injected water in the heat carrier is 1-50v%. The method can improve the yield of coal tar.

Owner:CHINA PETROLEUM & CHEM CORP +1

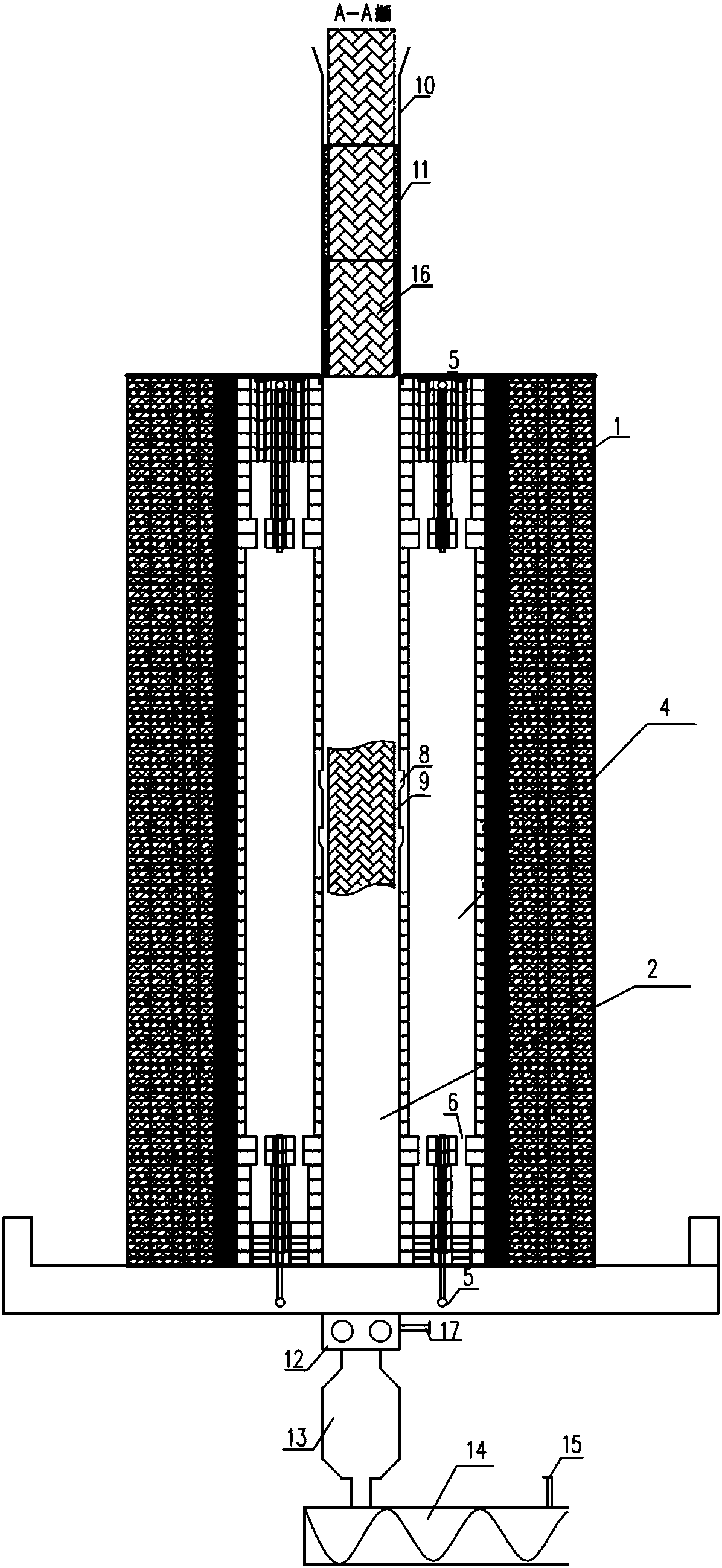

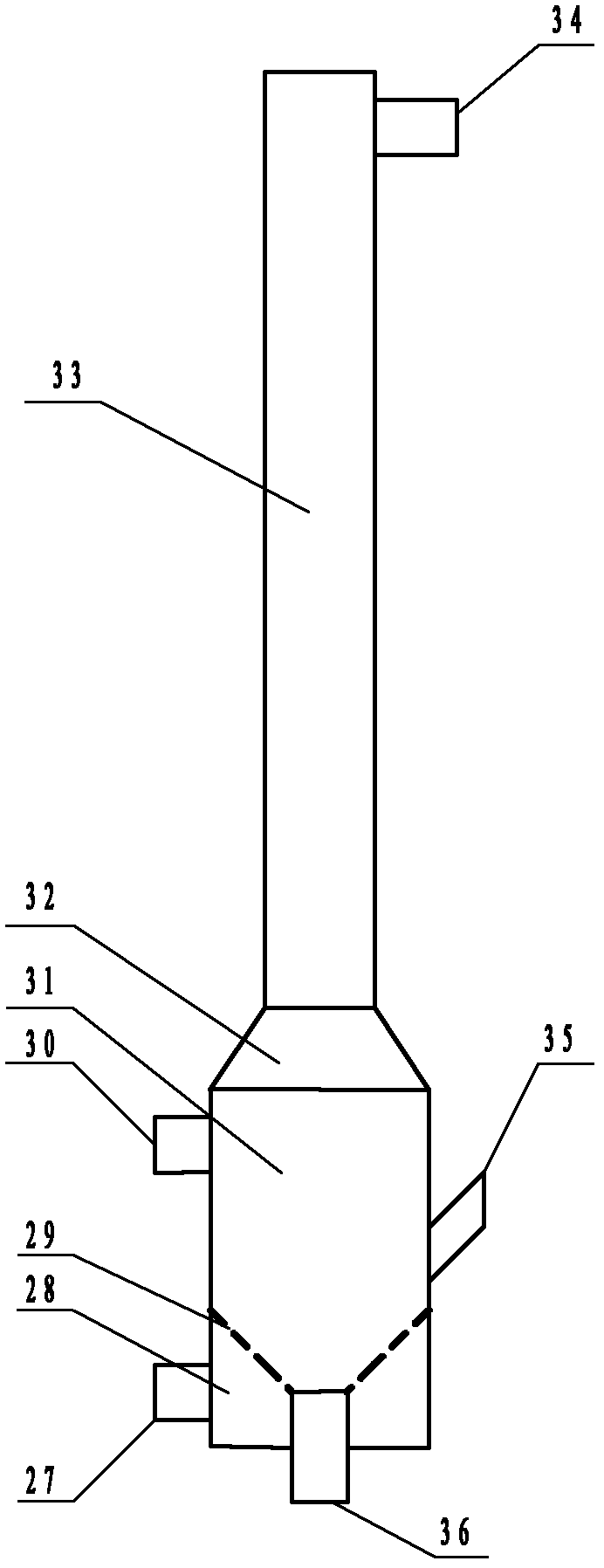

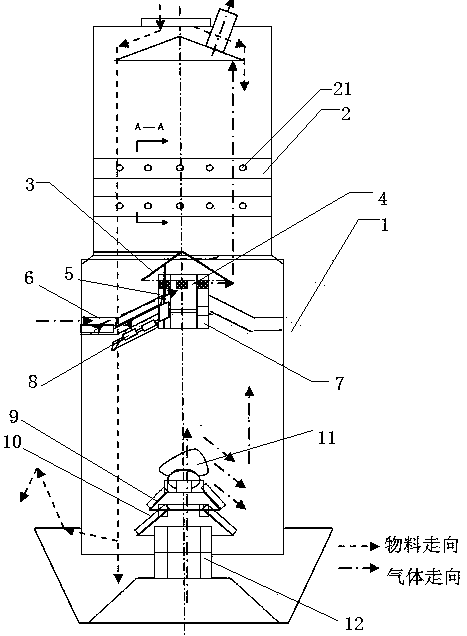

Novel dry distillation furnace for performing dry distillation on oil shale and processing process thereof

ActiveCN105602595AImprove breathabilityImprove drying and dry distillationDirect heating destructive distillationLiquid hydrocarbon mixture productionProcess engineeringDry distillation

The invention relates to a novel dry distillation furnace for performing dry distillation on oil shale. The novel dry distillation furnace comprises a furnace body, wherein a material distribution structure is arranged in a dry distillation section in the furnace body; an arch table wind shoe structure is arranged in a generating section; a gas distribution structure is arranged at the bottom in the furnace body. The novel dry distillation furnace has the advantages that the dry distillation cross section intensity can be increased to a value being 1500kg / m<2> or more which is higher than that of the existing fushun 100t / d furnace; the raw material processing quantity can be obviously improved; the oil yield can be improved by 10 percent or higher; the novel dry distillation furnace can realize the amplified design of the processing capability exceeding 100t / d; the small-proportion adaptive processing of small-particle oil shale of 20mm or below 20mm can be realized to a certain degree; a novel path is opened for small-particle oil shale oil refining in China.

Owner:LONGKOU MINING GRP

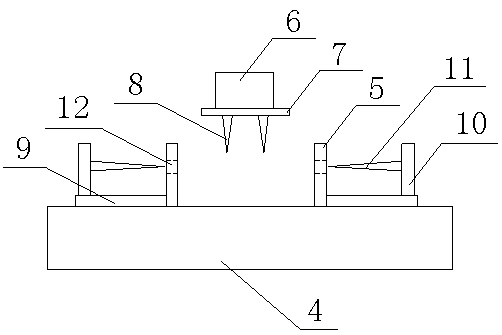

Combustible refuse compressed brick and combustible refuse compression device

ActiveCN106696334ASuitable for handlingDistilled evenlySpecial form destructive distillationPressesBrickLitter

The invention provides a combustible refuse compressed brick and a combustible refuse compression device. The destructive distillation effect of combustible refuse can be improved through the refuse compressed brick, and accordingly the reuse rate of the combustible refuse can be increased. The combustible refuse compressed brick is formed by compressing the combustible refuse. A brick body of the refuse compressed brick is provided with through holes. The combustible refuse compression device comprises a base, four side plates and a top plate connected with a stamping mechanism, and the four side plates are fixed to the periphery of the base. The top plate is provided with vertical columns protruding downwards. The base is provided with movable plates on the outer sides of the side plates. Protruding horizontal columns are arranged on the movable plates. The side plates are provided with through holes corresponding to the horizontal columns. Each movable plate is provided with a horizontal driving mechanism. The horizontal columns and the vertical columns are arranged in a staggered mode. The combustible refuse compression device is low in cost, and the through holes can be formed in the refuse compressed brick while the refuse is compressed, so that the destructive distillation effect of the refuse is improved, and the combustible refuse compression device is quite suitable for disposal of the combustible refuse.

Owner:赖德勤

Multistage pulverized coal multiple-tube rotary low temperature dry distillation technology and system

ActiveCN102358841BEasy to handleIncrease the heat exchange areaIndirect heating destructive distillationSpecial form destructive distillationCaloric valuesHelical blade

The invention discloses a multistage pulverized coal multiple-tube rotary low temperature dry distillation technology and system. The multiple-tube rotary dry distillation machine multistage (two stages or more) series connection process is adopted to perform low temperature dry distillation on pulverized coal; a plurality of dry distillation tubes are arranged in the multiple-tube rotary dry distillation machine to disperse coal powder, a helical blade is arranged in each dry distillation tube to guide and disturb coal and reinforce the dry distillation effect and increase the dry distillation effective area, the technology has the advantages of large pulverized coal treatment capacity, large dry distillation gas treatment capacity, low tar and dust contents, high coal gas caloric value and the like; the chemical raw materials generated in the low temperature dry distillation process of bituminous coal and low-price pulverized coal can be recycled extremely, the comprehensive utilization rate of coal is increased; and semicoke powder and coal gas with high calorific value can be produced through the low temperature dry distillation of bituminous coal and low-price pulverized coal.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

A kind of biomass dry distillation furnace and biochar preparation method

ActiveCN107779216BHigh recovery rateGuaranteed qualityCoke quenchingSpecial form destructive distillationProcess engineeringProduced water

The invention relates to the field of comprehensive utilization of biomass energy and discloses a biomass dry distillation furnace and a charcoal preparation method. The biomass dry distillation furnace comprises a biomass loading system, a dry distillation system, a retorting gas collection system and a charcoal discharge system, wherein a first humidifying apparatus is arranged in the charcoal discharge system; the charcoal enters the charcoal discharge system; the first humidifying apparatus sprays a humidifying medium; the humidifying medium reacts with the charcoal to produce water gas while cooling the charcoal. According to the biomass dry distillation furnace disclosed by the invention, high-efficiency externally-heated biomass dry distillation equipment can realize batch feeding,continuous dry distillation and continuous discharging of biomass blocks, has loading and closing functions and also has retorting gas collection and maximum heat reutilization functions. Moreover, the invention further provides a high-quality charcoal preparation method.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Co-production system and co-production method for biomass carbon, gas, wood tar and wood vinegar

InactiveCN101955780BFirmly connectedReasonable designBiofuelsPyroligneous acid productionBiomass carbonSocial benefits

The invention discloses a co-production system and a co-production method for biomass carbon, gas, wood tar and wood vinegar. The co-production system comprises a biomass dry distillation kettle, a high-temperature heating furnace, a water cooling device, a washing device, a liquid separation device, a gas storage tank, a water-ring vacuum pump, a compressor, wood tar storage tank and a wood vinegar storage tank, wherein the liquid separation device separates wood vinegar and wood tar in the mixed liquid obtained by gas-liquid separation of the water cooling device; the co-production method comprises the following steps: 1, charging; 2, high-temperature carbonization: water cooling and gas-liquid separation, washing, gas storage and separation and storage of liquid matters; and 3, obtaining of the biomass carbon after the high-temperature carbonization. The co-production system for the biomass carbon, gas, wood tar and wood vinegar has the advantages of reasonable design, convenient processing, simple mounting arrangement, easy operation and good effect; and the co-production method has the advantages of convenient realization, high yield, low cost, fast co-production and relatively high production purity and has obvious economic and social benefits and wide popularization and application prospect.

Owner:陕西亿鑫生物能源科技开发有限公司

Drying and dry distillation combined quality improving process and system for low rank coal

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

Quality-improving technique combining low-rank coal pneumatic drying with multi-tube revolving dry distillation and system for same

ActiveCN102433142BEasy dischargeLow investment costCoke quenchingEnergy inputHigh energyCoking wastewater

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

A high-efficiency carbonization treatment device for agricultural straw waste recycling

ActiveCN109135782BPlace stableSave human effortBiofuelsOven incrustations prevention/removalCarbonizationEnvironmental engineering

The invention belongs to the technical field of agricultural straw recycling and particularly discloses an efficient carbonizing treatment device for agricultural straw waste recycling. Aiming at problems of high labor force, low efficiency and poor environmental friendliness of a straw carbonizing treatment device, a scheme is put forward and includes that the efficient carbonizing treatment device comprises a tank, the outer wall of one side of the tank is provided with a heating port, a heater is arranged on the inner wall of the heating port, a supporting seat is welded to the outer wall of one side of the tank, supporting legs are welded to two corners of the outer wall of one side of the supporting seat and two corners of the bottom outer wall of the tank respectively, and a supporting table is welded to the outer wall of one side of the tank. Manpower saving is realized by mechanical straw compacting; by mounting of a vacuum pump, straw can be isolated from air to the great extent to improve dry distillation effects; by means of water cooling, a gas and steam mixture is cooled and separated into gas, liquid and dust in gas, and environmental pollution caused by direct emission of the mixture can be effectively avoided.

Owner:山西亚创环力农业科技产业股份有限公司

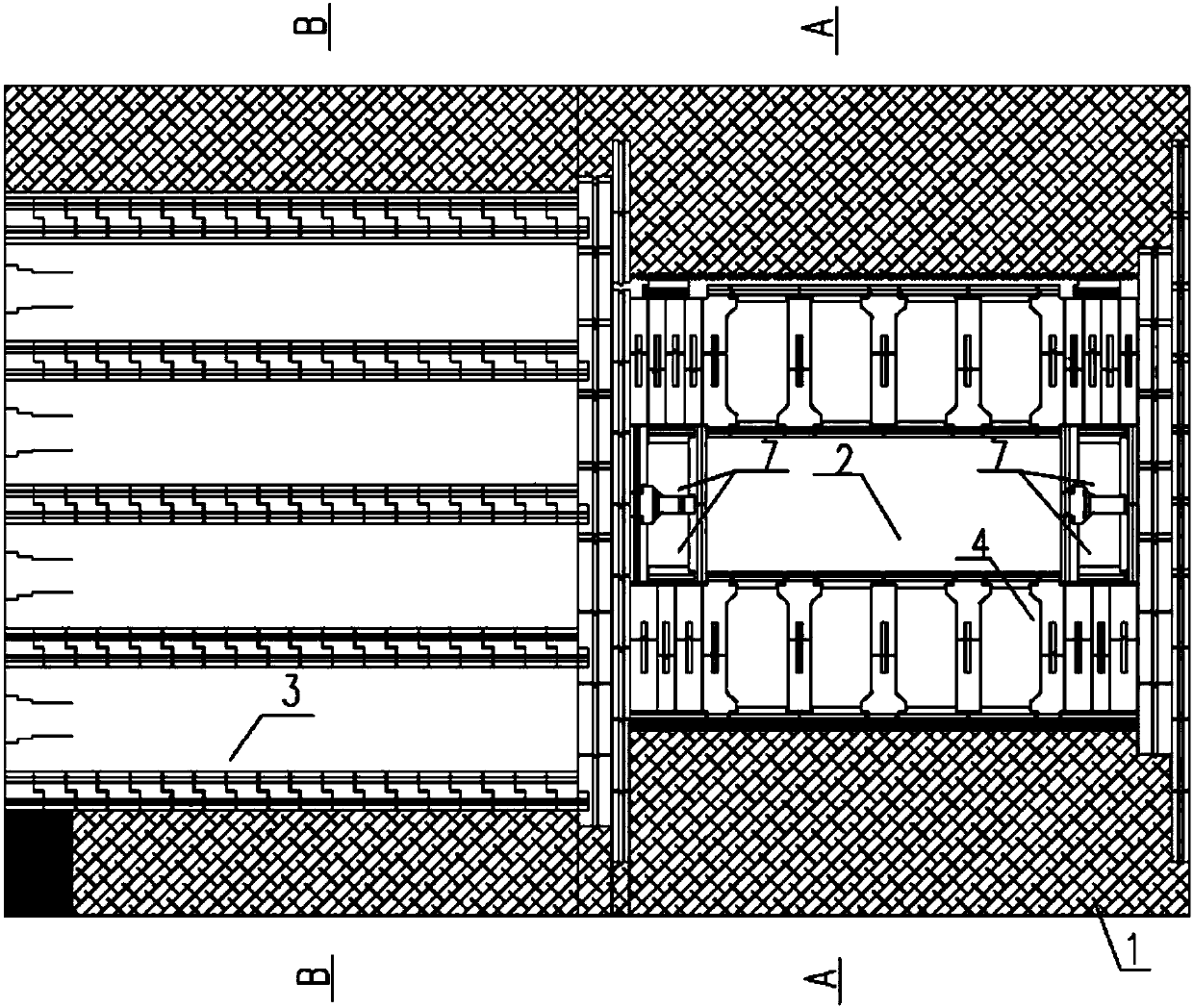

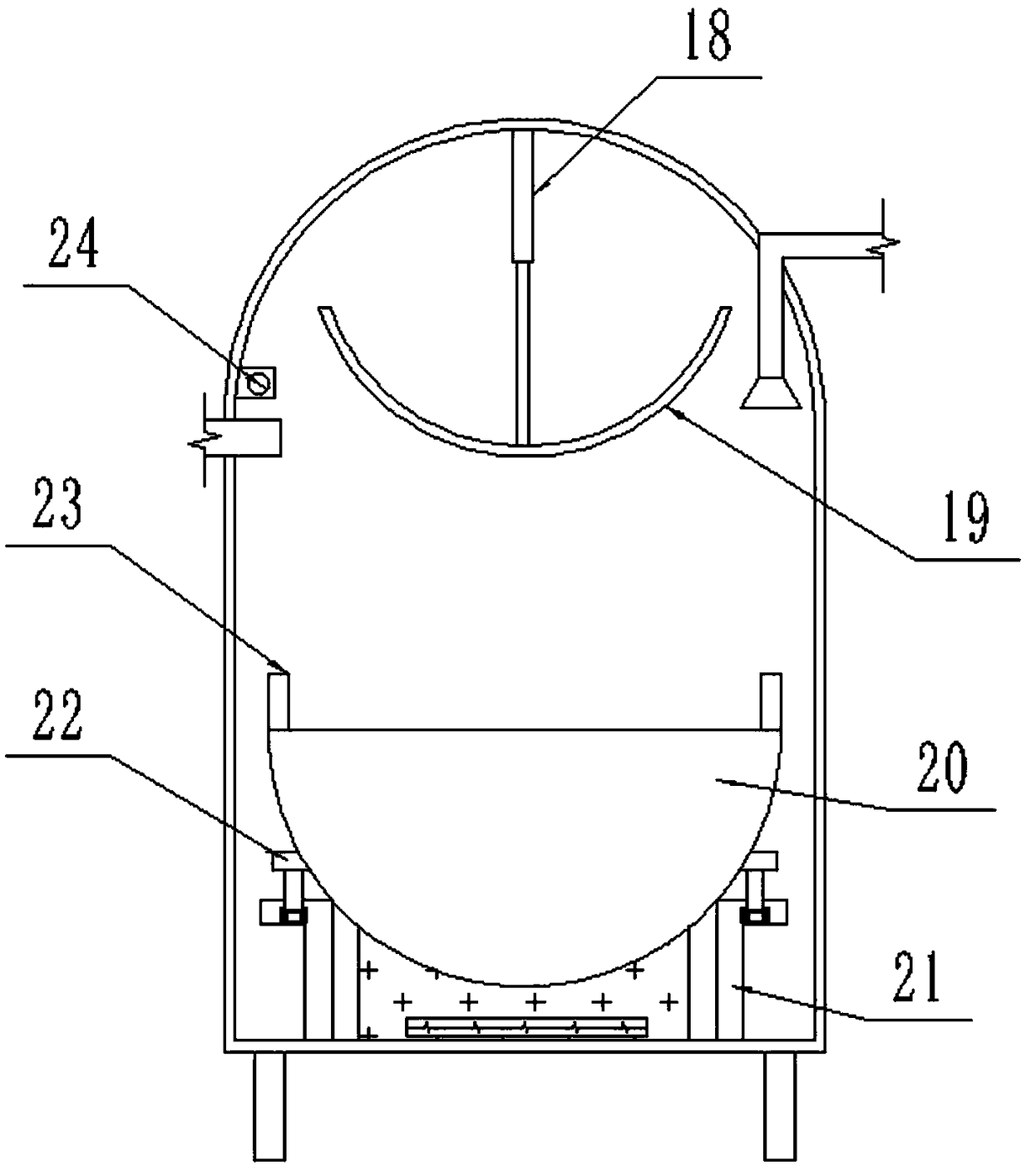

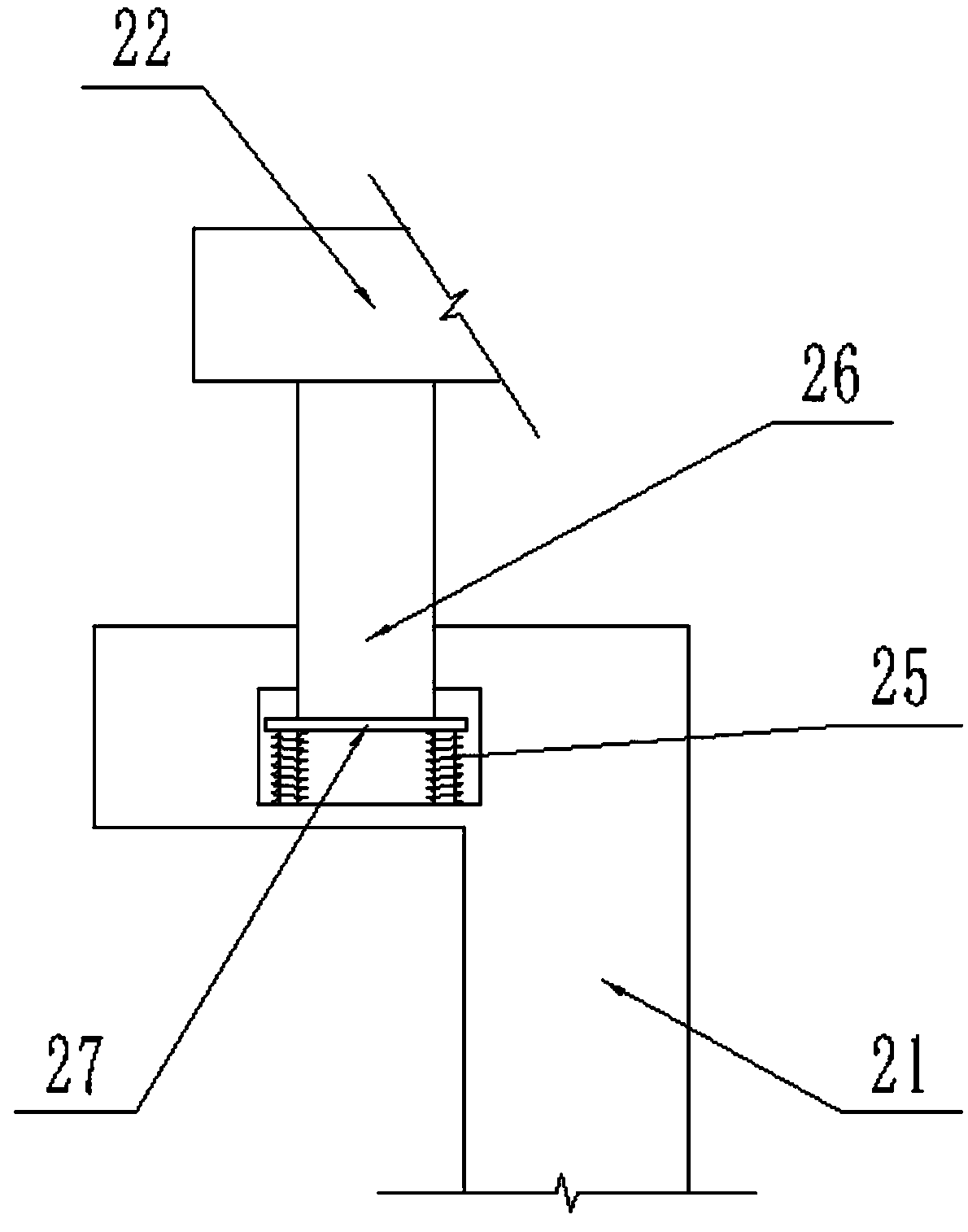

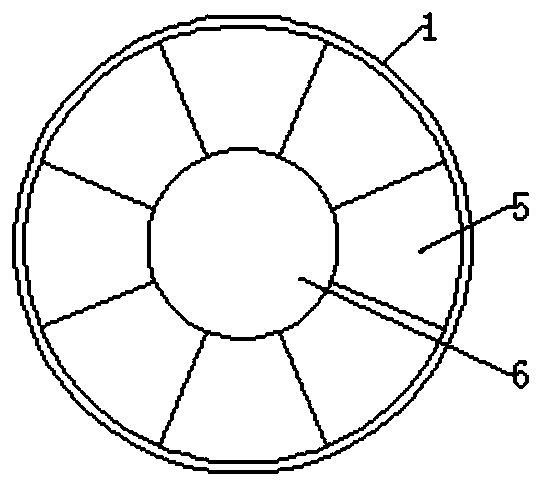

Continuous internal circulation dry distillation carbonization equipment

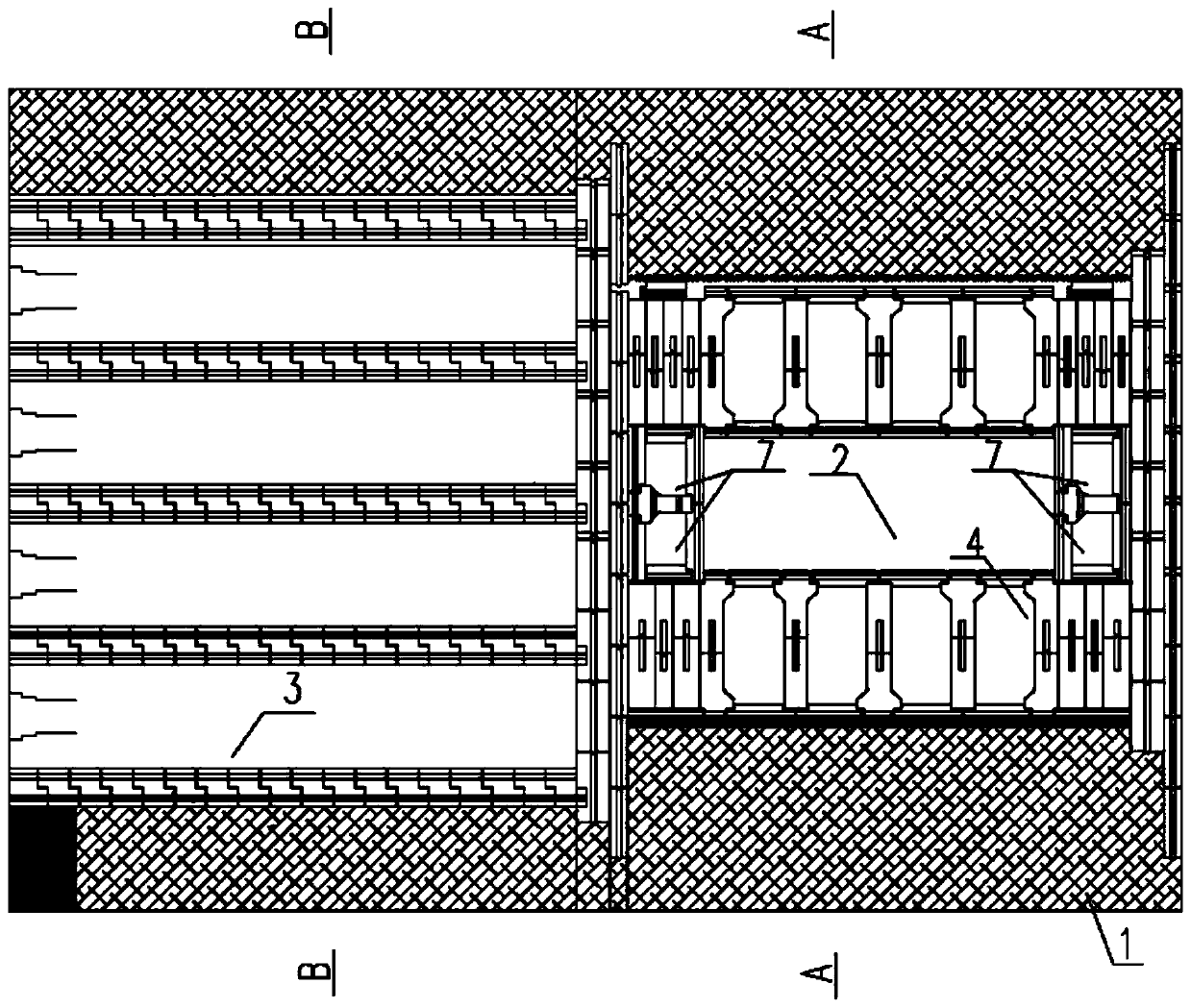

ActiveCN107325825BEasy accessLow densityBiofuelsIndirect heating destructive distillationProcess engineeringMechanical engineering

The invention discloses continuous inner-cycle dry distillation and carbonization equipment. The equipment comprises a combustion reaction chamber and a dry distillation kettle, wherein the combustion reaction chamber is hollow; the dry distillation kettle is a cylindrical column and is horizontally arranged in the combustion reaction chamber, a plurality of shin plates are arranged on the inner wall of the dry distillation kettle, rig plates are vertically arranged on two side plate surfaces of the shin plates, a first charcoal bin placed on the rig plates is arranged between each two adjacent shin plates, all the first charcoal bins form a circle coaxial with the dry distillation kettle, and meanwhile, second charcoal bins matched with the first charcoal bins are arranged in the circle; and a detachable first sealing cover and a detachable second sealing cover are respectively arranged at two ends of the dry distillation kettle, a rotating shaft is coaxially arranged at the outer end of the first sealing cover, and a flue is coaxially formed in the outer end of the second sealing cover and is communicated to the inside of the dry distillation kettle. The continuous inner-cycle dry distillation and carbonization equipment has the characteristics that the sintering time is saved, the uniform dry distillation and carbonization in a furnace body are realized, and the fetching and placement of an operator are facilitated.

Owner:梧州元泓机械设备有限公司

An energy-saving and environment-friendly wood-burning stove

ActiveCN106247410BPromote gasificationImprove stabilityDomestic stoves or rangesLighting and heating apparatusFirewoodHearth

The invention discloses an energy-saving and environment-friendly firewood burning furnace. The energy-saving and environment-friendly firewood burning furnace comprises a furnace shell and a hearth, and is characterized in that the furnace shell is of a closed cylindrical structure arranged outside the hearth in a sleeving manner, the hearth comprises a burning barrel and an outer barrel arranged on the outer side of the burning barrel in a sleeving manner, a gap is formed between the outer wall of the burning barrel and the outer barrel to form an airflow cavity, an air supply assembly communicating with the airflow cavity is arranged at the bottom of the outer barrel, and the burning barrel and the outer barrel are of a conical structure with the small upper portion and the large lower portion. According to the energy-saving and environment-friendly firewood burning furnace, the whole hearth is set to be of the conical structure, the air supply efficiency is improved, higher airflow can be obtained through burning, the air and fuel gas mixing ratio needed for premixed burning is achieved, pyrolysis of combustible molecules and better gasification of carbon particles are achieved, combustibles are completely burned to obtain high-heat-value fuel gas, accordingly, the higher hearth temperature and the continuous and stable furnace opening high temperature are obtained, the burning furnace opening temperature is continuously stabilized to be above 1,050 DEG C, energy consumption is low, and output is high.

Owner:成都市沛源五金制品有限公司

Single-stage fine coal multi-pipe rotary low-temperature destructive distillation technology and system

ActiveCN102358840BEasy to handleIncrease productivityIndirect heating destructive distillationSpecial form destructive distillationSingle stageSpiral blade

The invention discloses a single-stage fine coal multi-pipe rotary low-temperature destructive distillation technology and a system. The single-stage fine coal multi-pipe rotary low-temperature destructive distillation technology adopts a multi-pipe rotary destructive distillation machine to carry out low-temperature destructive distillation of fine coal. Multiple destructive distillation pipes for dispersing fine coal are arranged in the multi-pipe rotary destructive distillation machine. Spiral blades are arranged in the destructive distillation pipes and have the effects of diversion and disturbance on coal. The single-stage fine coal multi-pipe rotary low-temperature destructive distillation technology and the system can enhance destructive distillation effects, can increase destructive distillation effective areas, have the advantages of large fine coal treatment amount, small destructive distillation gas treatment amount, low content of tar and dust, and high calorific value of gas, can realize recovery of chemical raw materials such as coal tar and the like produced in low-temperature destructive distillation of soft coal and low-order fine coal as completely as possible, can improve a comprehensive utilization rate of coal, and can realize production of semicoke powder and high-calorific value gas from soft coal and low-order fine coal through low-temperature destructive distillation.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

A new type of dry distillation furnace and its processing process for dry distillation of oil shale

ActiveCN105602595BKeep dryImprove retort effectDirect heating destructive distillationLiquid hydrocarbon mixture productionEngineeringOil shale gas

The invention relates to a novel dry distillation furnace for performing dry distillation on oil shale. The novel dry distillation furnace comprises a furnace body, wherein a material distribution structure is arranged in a dry distillation section in the furnace body; an arch table wind shoe structure is arranged in a generating section; a gas distribution structure is arranged at the bottom in the furnace body. The novel dry distillation furnace has the advantages that the dry distillation cross section intensity can be increased to a value being 1500kg / m<2> or more which is higher than that of the existing fushun 100t / d furnace; the raw material processing quantity can be obviously improved; the oil yield can be improved by 10 percent or higher; the novel dry distillation furnace can realize the amplified design of the processing capability exceeding 100t / d; the small-proportion adaptive processing of small-particle oil shale of 20mm or below 20mm can be realized to a certain degree; a novel path is opened for small-particle oil shale oil refining in China.

Owner:LONGKOU MINING GRP

Combustible garbage compression device

ActiveCN106696334BSuitable for handlingDistilled evenlySpecial form destructive distillationPressesBrickCompression device

The invention provides a combustible refuse compressed brick and a combustible refuse compression device. The destructive distillation effect of combustible refuse can be improved through the refuse compressed brick, and accordingly the reuse rate of the combustible refuse can be increased. The combustible refuse compressed brick is formed by compressing the combustible refuse. A brick body of the refuse compressed brick is provided with through holes. The combustible refuse compression device comprises a base, four side plates and a top plate connected with a stamping mechanism, and the four side plates are fixed to the periphery of the base. The top plate is provided with vertical columns protruding downwards. The base is provided with movable plates on the outer sides of the side plates. Protruding horizontal columns are arranged on the movable plates. The side plates are provided with through holes corresponding to the horizontal columns. Each movable plate is provided with a horizontal driving mechanism. The horizontal columns and the vertical columns are arranged in a staggered mode. The combustible refuse compression device is low in cost, and the through holes can be formed in the refuse compressed brick while the refuse is compressed, so that the destructive distillation effect of the refuse is improved, and the combustible refuse compression device is quite suitable for disposal of the combustible refuse.

Owner:赖德勤

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com