Municipal sludge destructive distillation carbonation test system

A technology of carbonization test and municipal sludge, which is applied in the field of environmental engineering, can solve problems such as variable mud quality and complex sludge composition, and achieve the effects of accelerating carbonization speed, facilitating sampling and analysis, and improving control of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

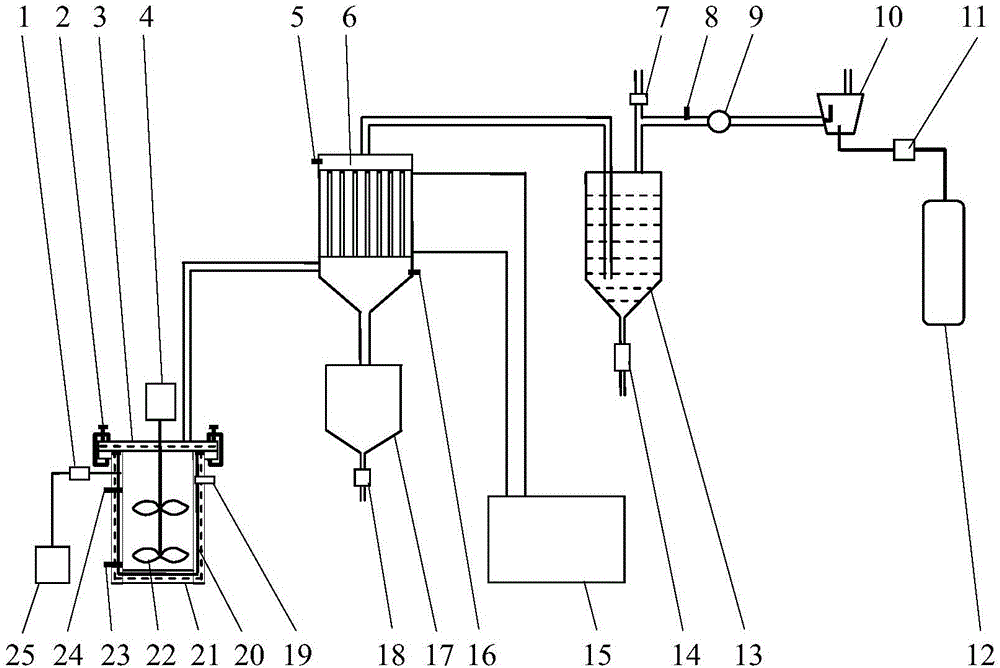

[0010] The present invention will be further described in detail below with reference to the accompanying drawings, see the accompanying drawings.

[0011] A test system for dry distillation and carbonization of municipal sludge. The test system consists of a dry distillation reaction device, a gas-liquid collection device, a gas processing device and a control device. The dry distillation reaction device consists of a first gas control valve 1, a locking button 2, and a reaction vessel cover 3. , Motor 4, barometer 19, heating device 20, reaction kettle 21, stirrer 22, first temperature sensor 23, second temperature sensor 24 and vacuum pump 25. The reaction kettle 21 is in a sandwich shape, and the reaction kettle 21 is set in the sandwich There is a heating device 20 and a heat insulation layer. The heat insulation layer is located between the heating device 20 and the outer interlayer of the reactor 21. The upper part of the wall of the reactor 21 is provided with a first temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com