Co-production system and co-production method for biomass carbon, gas, wood tar and wood vinegar

A technology of biomass charcoal and wood vinegar, which is applied in the direction of biofuel, gas purification of condensed non-gaseous materials, petroleum industry, etc., and can solve problems such as imperfect functions and immature co-production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

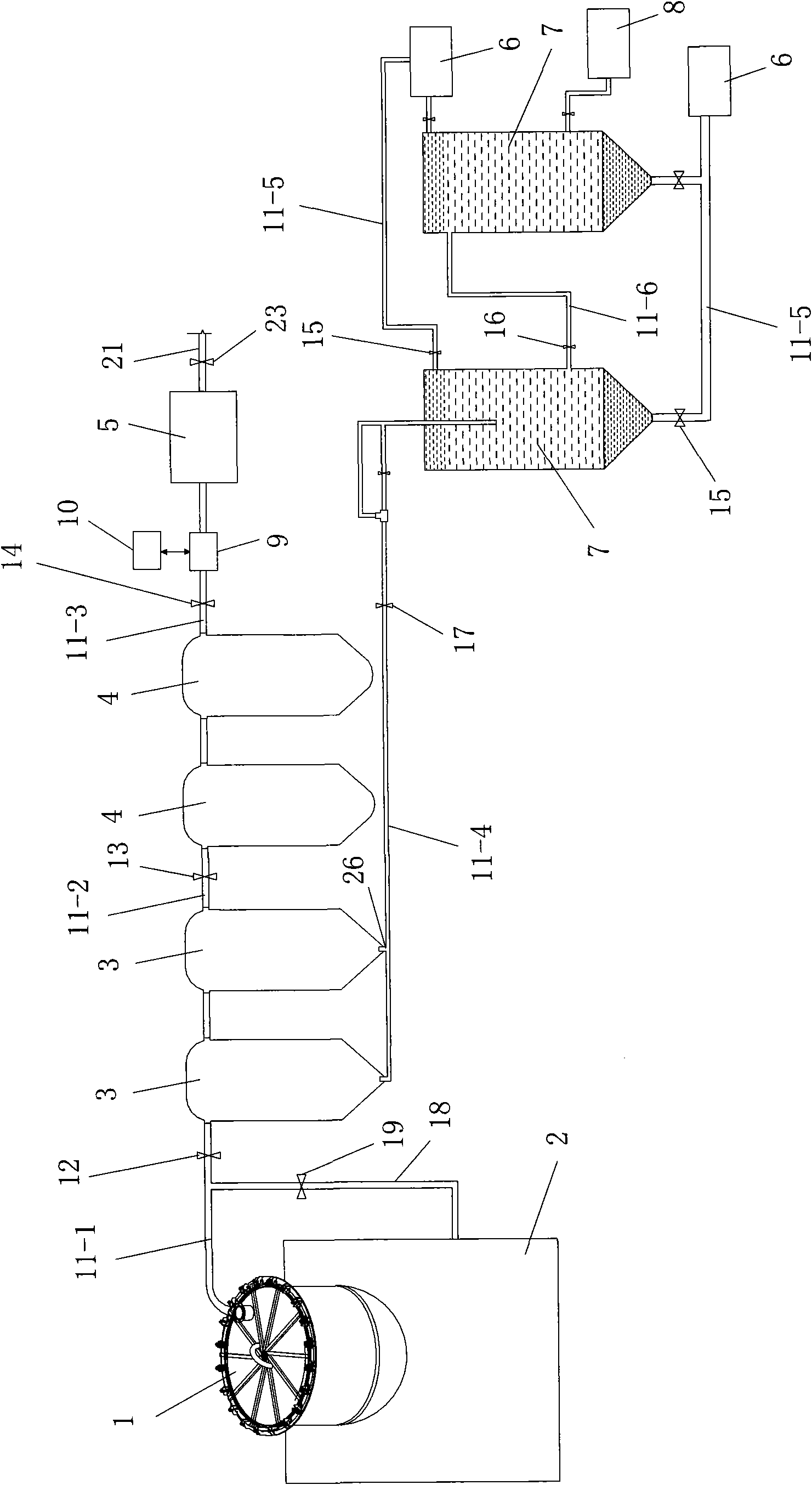

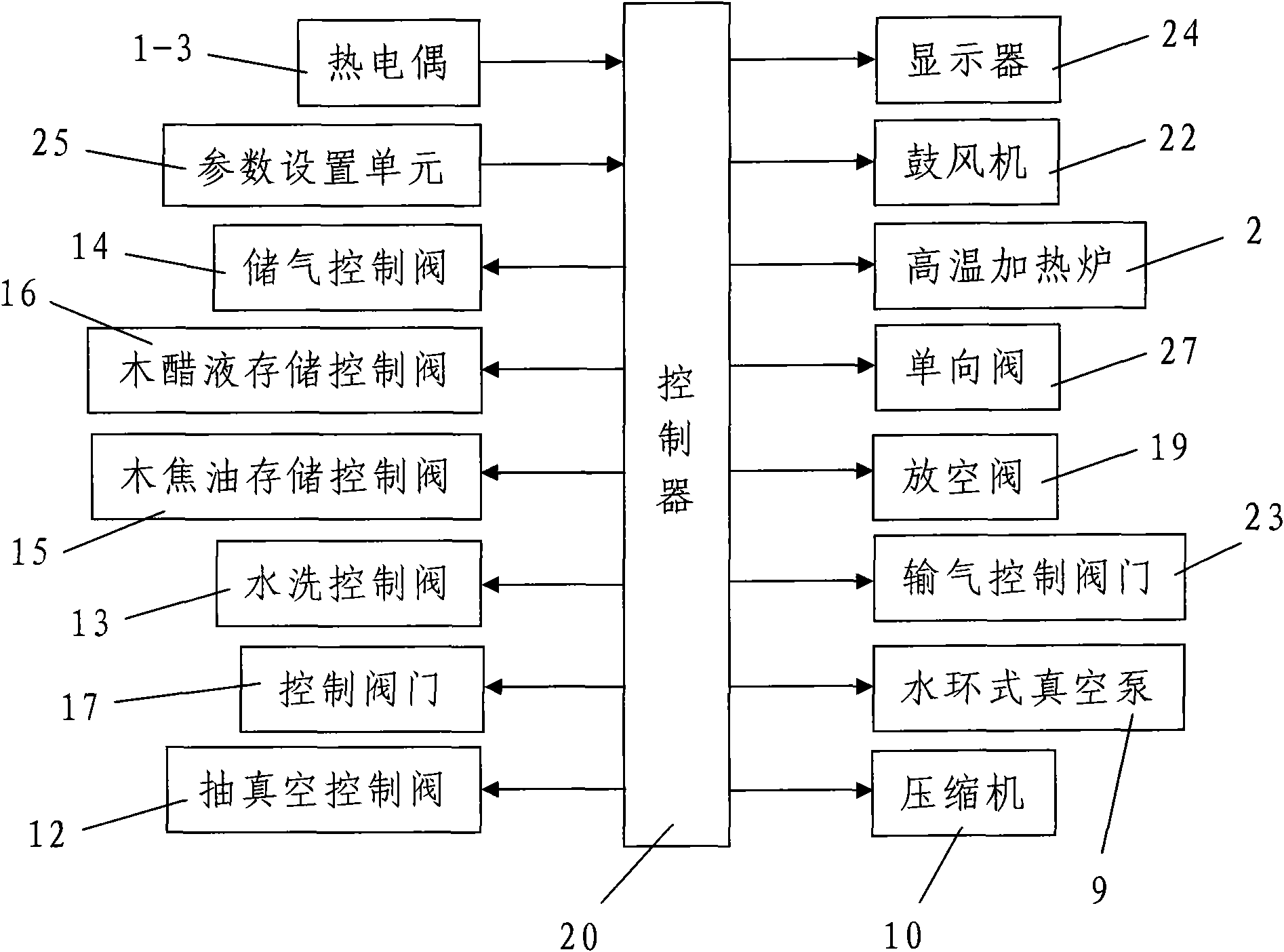

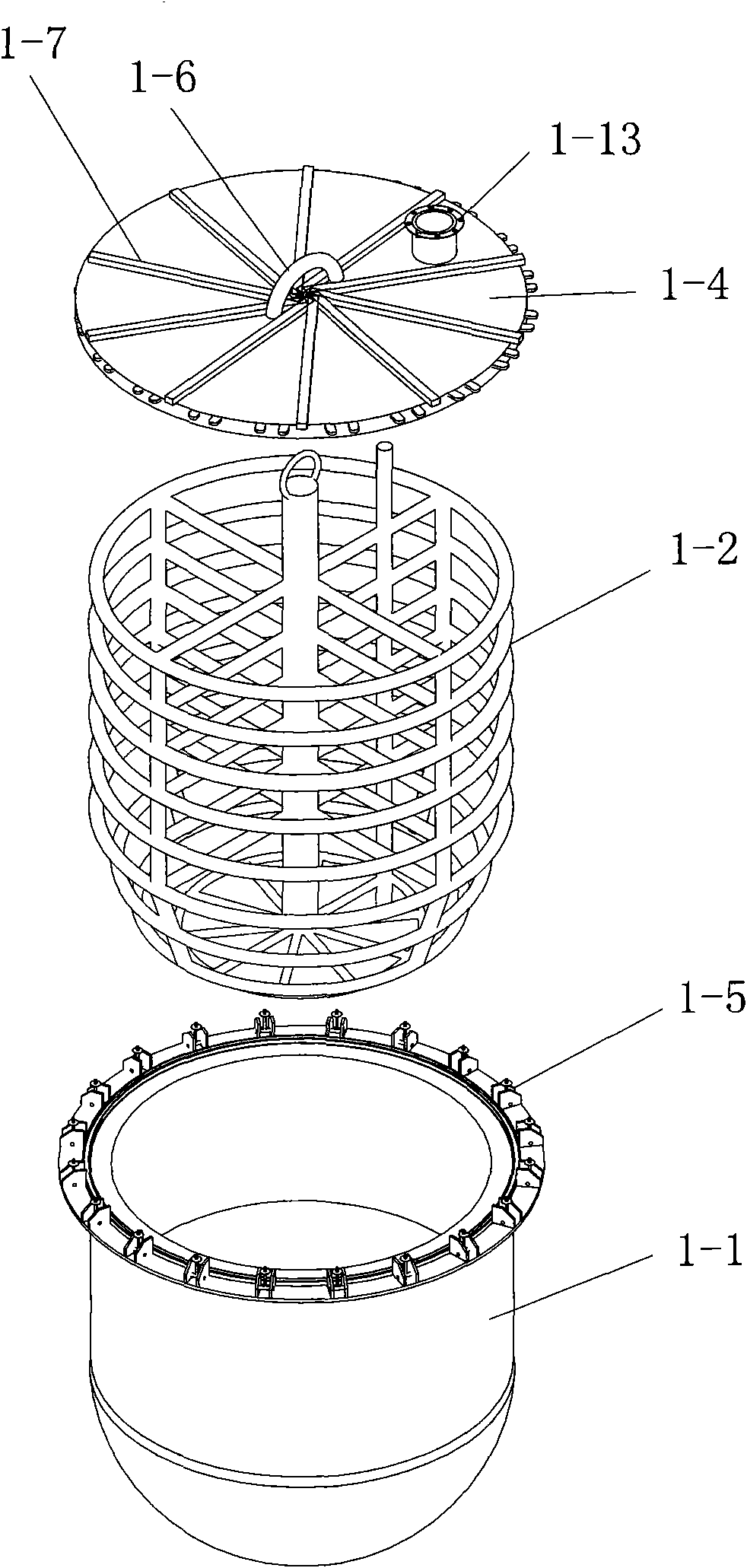

[0078] Such as figure 1 , figure 2 A kind of biomass charcoal, gas, oil and wood vinegar liquid co-production system shown, comprises biomass carbonization still 1, carries out the high-temperature heating furnace 2 that carries out high-temperature carbonization to the vegetation raw material in biomass carbonization still 1, to described The mixed gas produced in the high-temperature carbonization process of grass and wood raw materials is cooled and the mixed gas is separated from the gas and liquid simultaneously, and the water cooling device 3 for obtaining the mixed gas 2 and the mixed liquid is obtained after being cooled by the water cooling device 3 The mixed gas 2 is washed with water to obtain wood gas correspondingly 4, the liquid separation device 7 for separating the wood vinegar and wood tar in the mixed liquid separated from the gas-liquid by the water cooling device 3, and the wood gas Storage tank 5, water ring vacuum pump 9 and compressor 10 connected with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com