Coal carbonization and coal catalytic cracking combined process

A catalytic cracking and combined process technology, applied in special forms of dry distillation, direct heating dry distillation, petroleum industry and other directions, can solve the problems of processing and utilization, low output of a single furnace, restricting the use of semi-coke products, etc., and achieve the effect of promoting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

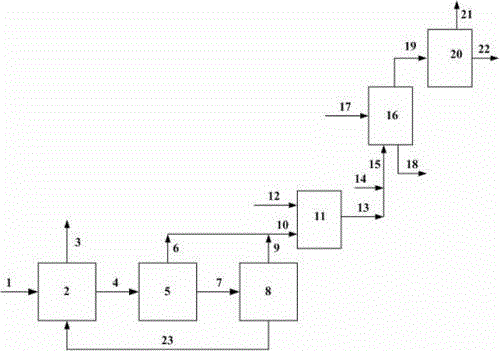

Method used

Image

Examples

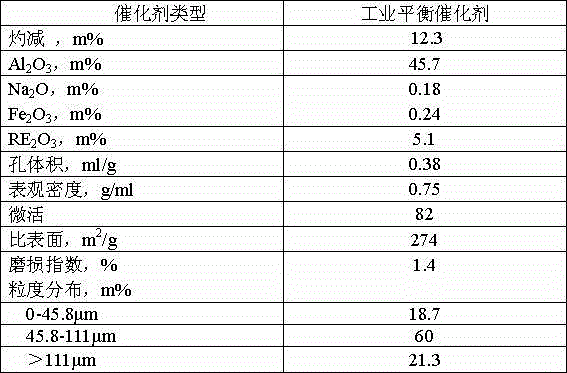

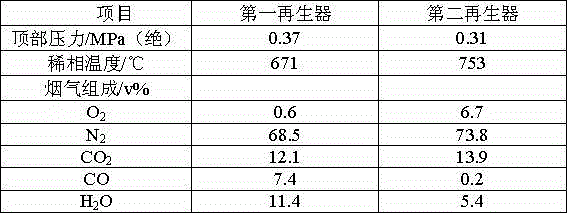

Embodiment 1

[0025] The catalytic cracking reaction is carried out on a small riser catalytic cracking unit. The catalytic cracking catalyst used in the examples is an industrial equilibrium catalyst (see Table 1 for properties of the fresh catalyst). Hydrogenated residual oil (>350°C) is used as catalytic cracking raw material, the test conditions are: reaction temperature 520°C, solvent-oil ratio 6:1, space velocity 10h -1 . The operating data and flue gas composition of the regenerator are shown in Table 2. Lignite A from a certain area in northern Shaanxi was selected, and its industrial analysis is shown in Table 3. After the raw coal is crushed and screened, the pulverized coal <6mm is added to the fluidized bed carbonization reactor, and the mixture of primary flue gas and secondary flue gas and air are burned in the CO incinerator, and the temperature of the flue gas at the outlet of the incinerator is controlled At 800°C, add water to the heat carrier, the volume of water conve...

Embodiment 2

[0037] The reaction is carried out on a small riser type catalytic cracking unit. The catalytic cracking catalyst used in the examples is an industrial equilibrium catalyst (see Table 1 for properties of the fresh catalyst). Hydrogenated residual oil (>350°C) is used as catalytic cracking raw material, the test conditions are: reaction temperature 520°C, solvent-oil ratio 6:1, space velocity 10h -1 . The operating data and flue gas composition of the regenerator are shown in Table 5. Lignite A from a certain area in northern Shaanxi was selected, and its industrial analysis is shown in Table 2. After the raw coal is crushed and screened, the pulverized coal <6mm is added to the fluidized bed dry distillation reactor, and the mixture of primary flue gas and secondary flue gas is burned in the high-temperature flue, and the temperature of the flue gas at the outlet of the high-temperature flue is controlled. At 1000°C, add water to the heat carrier, the volume of water conver...

Embodiment 3

[0049] Pass through cyclohexanol vapor in the heat carrier that feeds water vapor, the volume content of cyclohexanol vapor in heat carrier is 2%, all the other are the same as embodiment 1, and product distribution is shown in Table 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com