Single-stage fine coal multi-pipe rotary low-temperature destructive distillation technology and system

A pulverized coal and dry distillation technology, applied in the field of single-stage pulverized coal multi-tube rotary low-temperature dry distillation process and system, can solve the problems of large hot semi-coke circulation, complex process system, and difficult operation, and achieve large processing capacity and enhanced Dry distillation effect, effect of improving heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

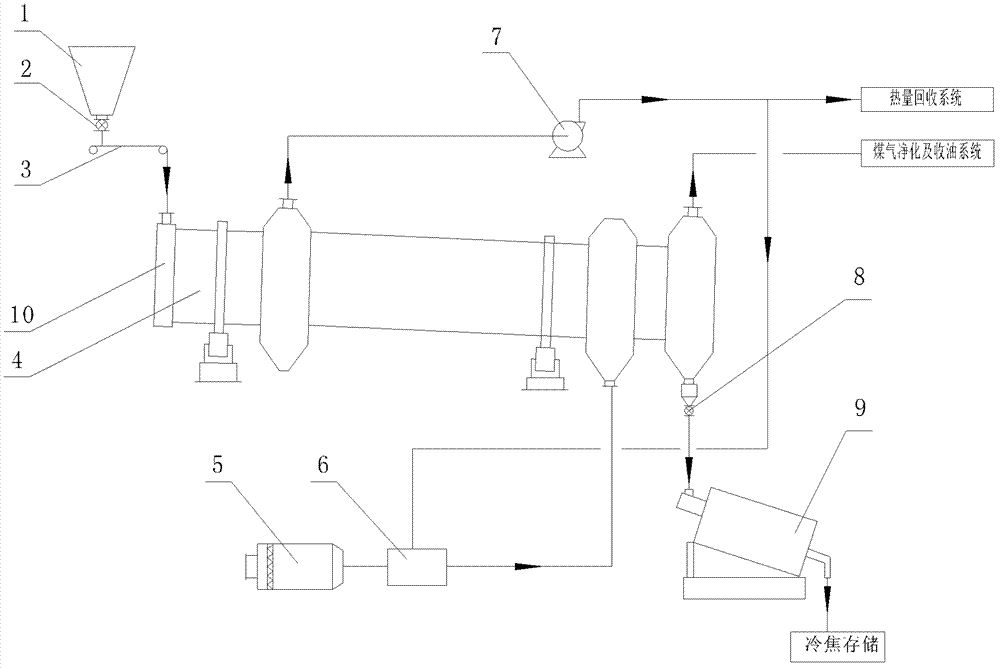

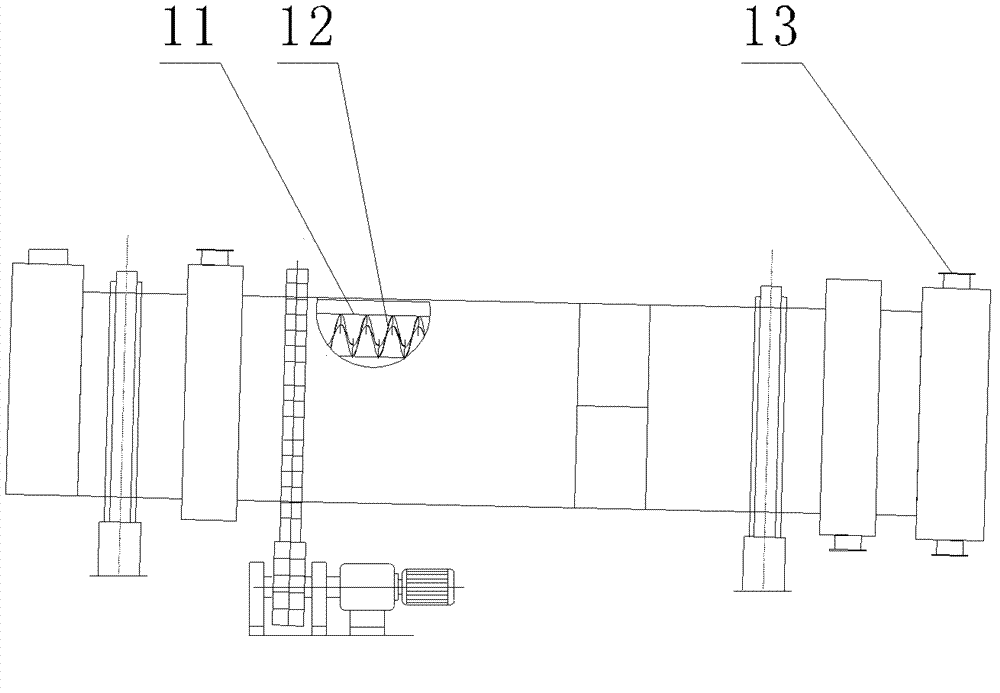

[0040] Such as figure 1 , 2 As shown, the single-stage pulverized coal multi-tube rotary low-temperature retort system includes a multi-tube rotary retort 4, the multi-tube pulverized coal feeder 10 at the front end of the multi-tube rotary retort 4 is connected to the feeding device, and the multi-tube rotary retort The discharge port of machine 4 is connected with cold coke machine 9 through high temperature unloading valve 8; The gas outlet is respectively connected to the air mixing chamber 6 and the flue gas recycling system through the induced draft fan 7; the retort gas guide port of the multi-pipe rotary retort 4 is connected to the gas purification and tar collection system.

[0041] The feeding device includes conveying equipment 3 corresponding to the multi-pipe pulverized coal feeder 10, the upper part of the conveying equipment 3 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com