Combustible garbage compression device

A garbage compression and combustible garbage technology, applied in presses, manufacturing tools, special forms of dry distillation, etc., can solve the problems of dry distillation failure, insufficient heating of garbage, etc., and achieve the effect of improving gas circulation, low cost, and improving dry distillation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

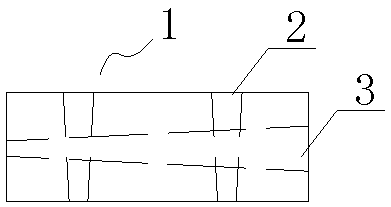

[0019] As shown in the figure, the combustible garbage compression brick of this embodiment is formed by compressing combustible garbage. The key is that the brick body of the garbage compression brick 1 is provided with a tapered vertical through hole 2 and a horizontal through hole 3, wherein the vertical through hole 2 and the horizontal through hole The horizontal through-holes 3 are staggered and do not communicate with each other.

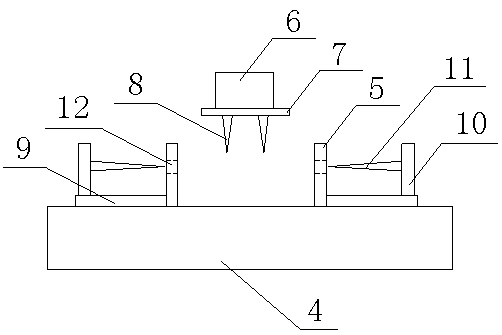

[0020] The combustible waste compression device used to manufacture the above-mentioned combustible waste compression brick 1 includes a base 4, a side plate 5 and a top plate 7 connected with a stamping mechanism 6, and there are four side plates 5, which are fixed around the base 4; The top plate 7 is provided with a downward protruding vertical column 8; the base 4 is provided with a guide rail 9 and a movable panel 10 on the outside of the side panel 5, and the movable panel 10 is erected on the guide rail 9 and advances along the guide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com