Biomass dry distillation furnace and charcoal preparation method

A technology of biomass and retort furnace, which is applied in special forms of retort, retort gas discharge device, coke oven, etc. It can solve the problems of low heat recovery utilization rate, poor quality of retort products, and uncontrollable discharge speed, etc., and achieve improvement Heat recovery rate, effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

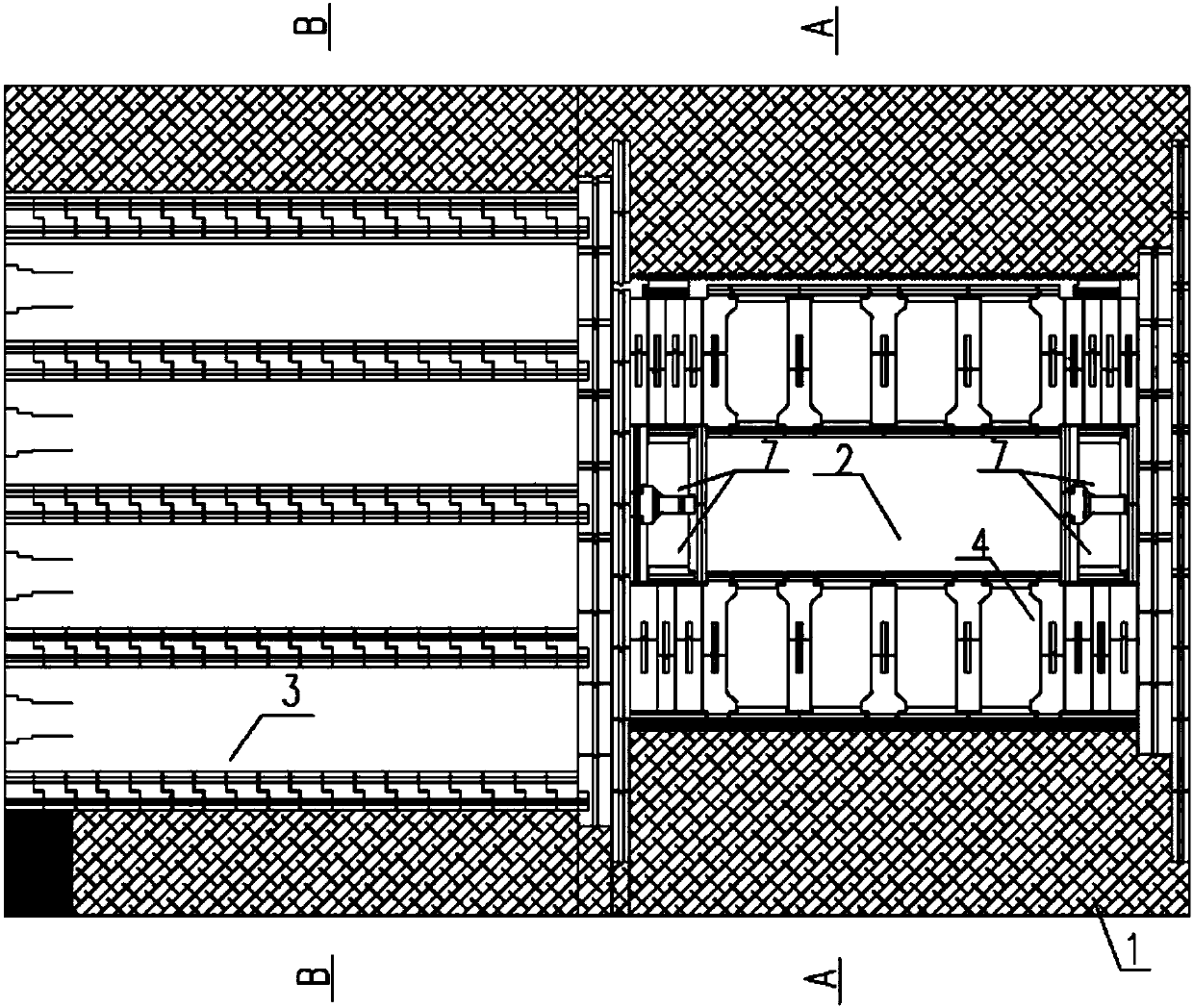

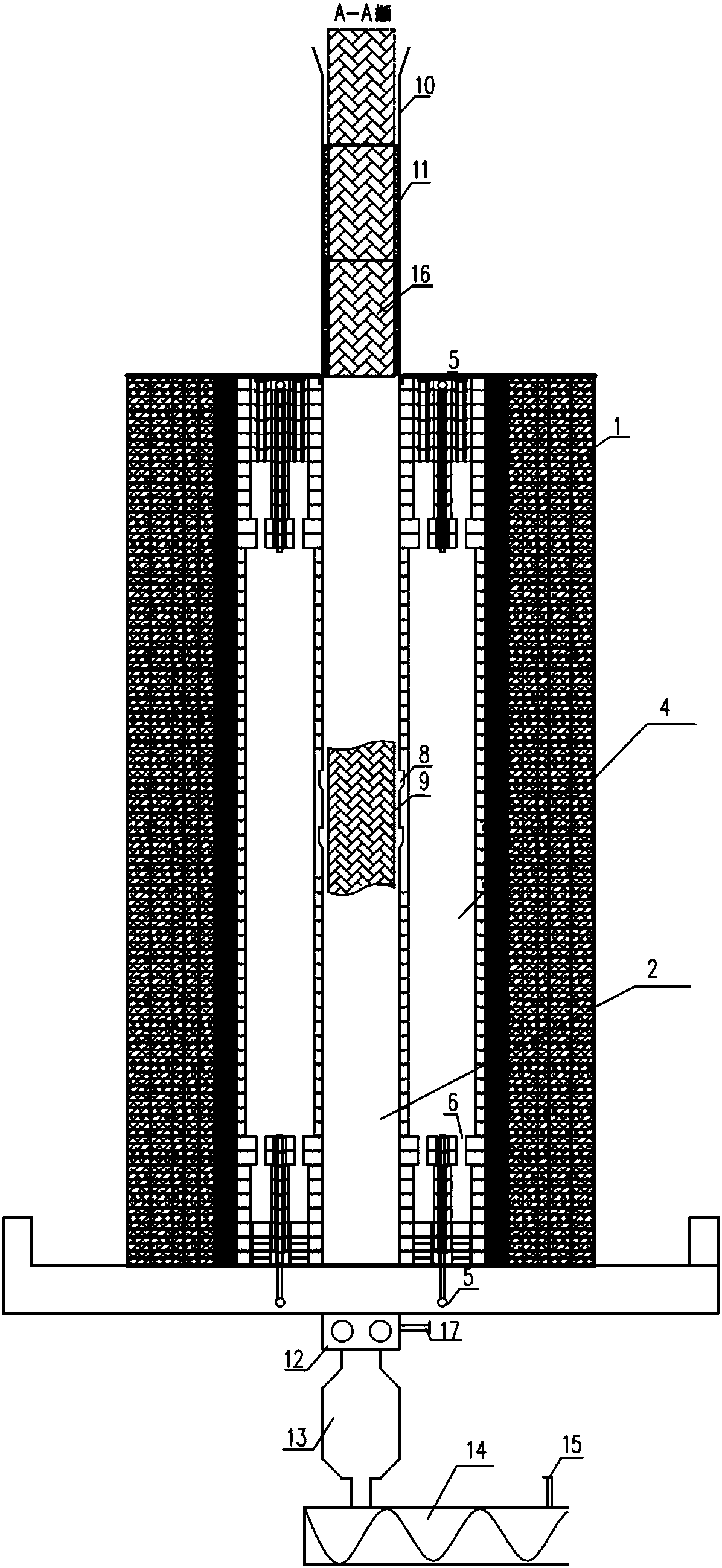

[0035] This embodiment provides a biomass carbonization furnace, such as figure 1 , figure 2 with image 3 As shown, including: biomass loading system, dry distillation system, dry distillation gas collection system and biochar discharge system.

[0036]Biomass loading system, comprising: feeding device 10, sealing section 11 arranged at the lower part of the feeding device 10; biomass is pre-dried in the sealing section 11 by using the heat of the retort furnace to ensure that the biomass is The water content of the system is reduced by 5-10%. At the same time, the water vapor or inert gas generated by the biomass itself acts as an auxiliary seal to isolate the outside air from entering and avoid the continuous upward transfer of heat in the carbonization system.

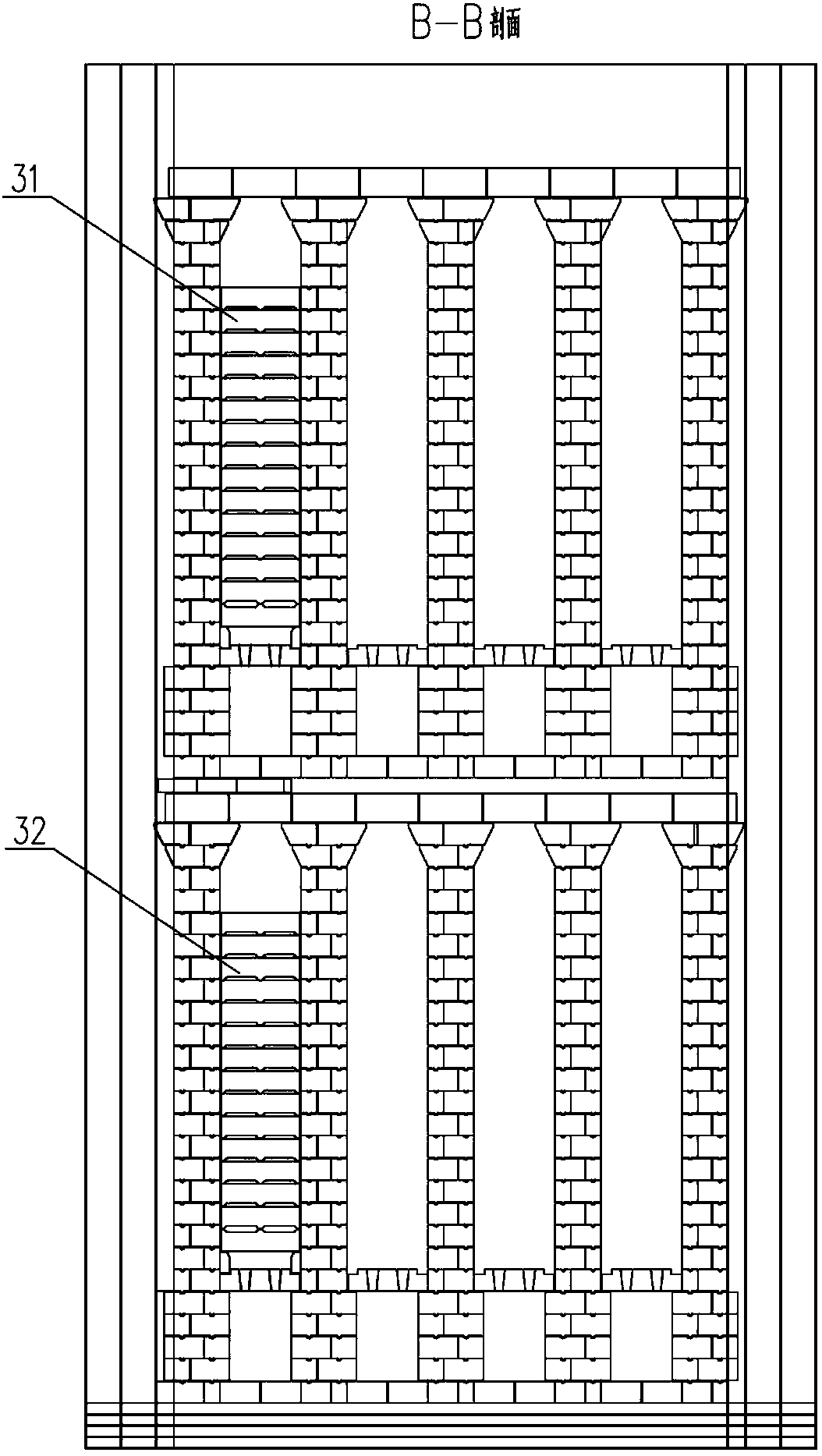

[0037] The retort system includes: a retort furnace body 1, a retort chamber 2 arranged inside the retort furnace body 1, a combustion chamber vertical fire passage 4, and a fire chamber 4 arranged at the upper ...

Embodiment 2

[0042] This embodiment provides a method for preparing biochar using the biomass carbonization furnace described in Embodiment 1, comprising the following steps:

[0043] S1. Biomass loading step

[0044] The biomass material is bundled and / or compressed into tangible biomass blocks 16, and sent into the feed device 10 through conveying equipment, such as conveyors and elevators, and then compacted, and the biomass blocks 16 Buffer and seal at the sealing section 11, and charge to the dry distillation system; the density of the biomass block 16 is 0.1-1.1g / cm 3 , relative dry basis moisture content of 2 to 40%. As an embodiment of the present invention, in this embodiment, the biomass block 16 density is 0.6g / cm 3 , The relative dry basis moisture content is 21%.

[0045] S2. Biomass dry distillation step

[0046] Biomass blocks 16 are continuously and evenly moved downwards by their own gravity during the dry distillation in the dry distillation system, and biochar is obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com