A solid fuel spiral dry distillation machine

A solid fuel and retort technology, which is applied in the fields of biofuel, indirect heating retort, special form retort, etc., can solve the problems of uneven heating of fuel, large fuel processing capacity of retort furnace, and reduction of carbon production, so as to improve energy utilization efficiency. , The material is heated quickly, and the effect of the heating surface of the fuel is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

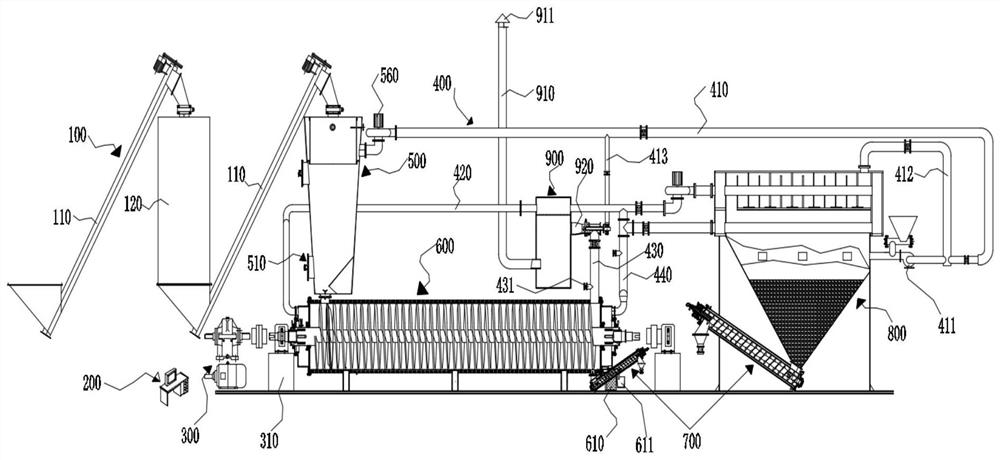

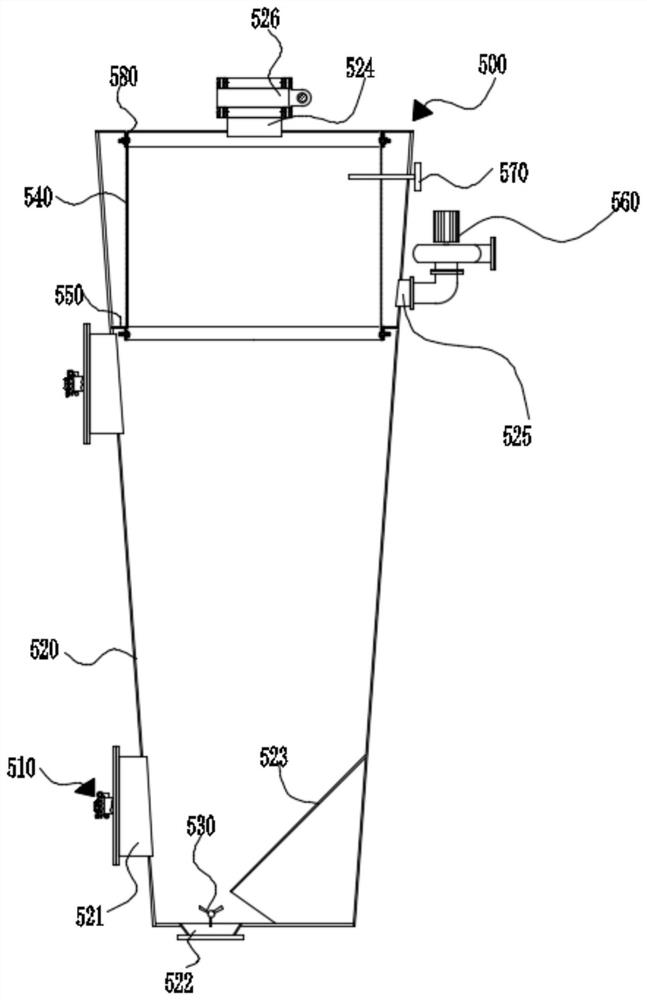

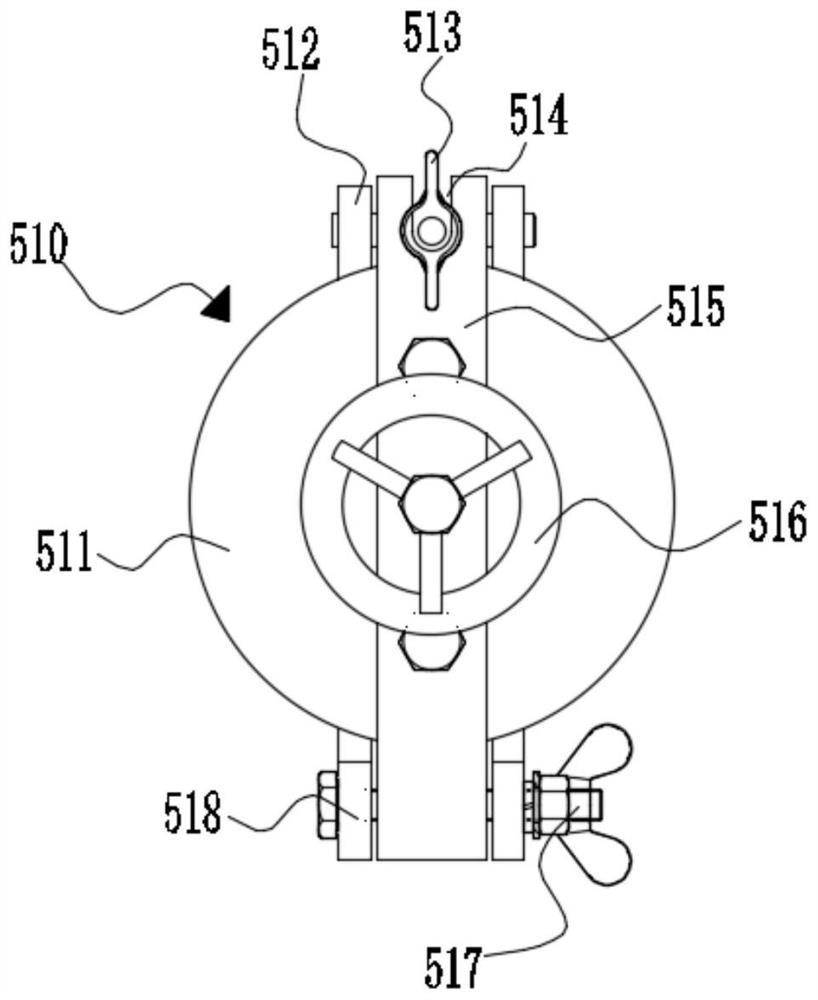

[0047] see figure 1 , in this embodiment, a solid fuel spiral carbonization machine, including a feeding device 100, a fuel filter 500, a carbonization device 600, a temperature unloading charcoal device 700, and a curved hot blast stove 800, which are used to connect the above devices and form an air flow path The pipe fittings 400 and the DCS electric control cabinet 200 for controlling the operation of the above-mentioned equipment, wherein the feeding equipment 100 is used for sealing and feeding solid fuels (such as agricultural and forestry crop straw, new firewood scraps, shale sludge, etc.); The fuel filter 500 is used to heat replace the air entrained in the solid fuel fed by the feeding device 100, and send the replaced air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com