Heat storage type heating separating device

A heat storage device and separation device technology, which is applied in indirect heating carbonization, coking oven with horizontal carbonization chamber, petroleum industry, etc., can solve the problems of poor carbonization effect and poor gas purity, so as to improve the effect and avoid bias flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

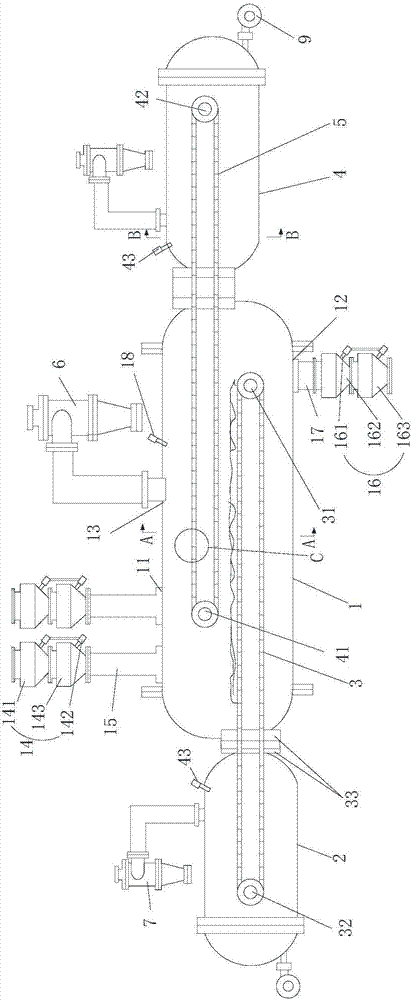

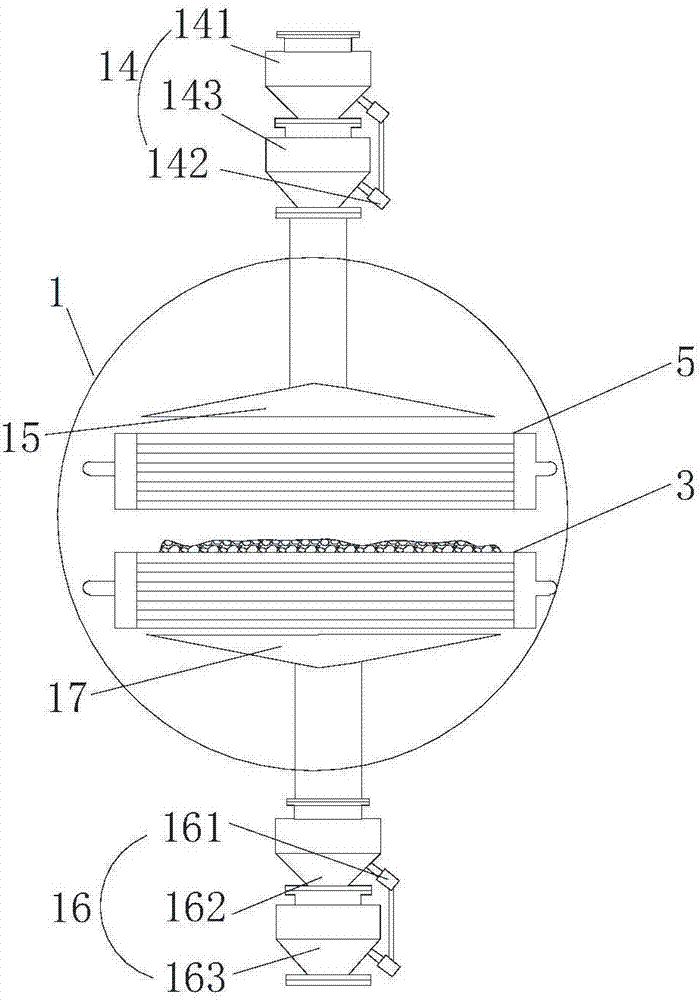

[0065] Such as figure 1 As shown, the present invention provides a regenerative heating separation device, which has the characteristics of good dry distillation effect, good dry distillation gas phase quality, and high dry distillation efficiency, comprising a dry distillation device 1, a first heating device 2, a first heat storage device 3 and The first driving device, the carbonization device 1 is a hollow structure, and a carbonization chamber for carbonizing materials is arranged inside. The top of the carbonization device 1 is provided with at least one feed port 11 and a gas outlet 13, and the lower part of the carbonization device 1 is provided with a discharge port 12. ; The dry distillation device 1 is used for dry distillation of the materials placed therein;

[0066]In the present invention, the first heating device 2 is arranged on the left side of the carbonization device 1, and the first heating device 2 is used to heat and store the first heat storage device 3...

Embodiment 2

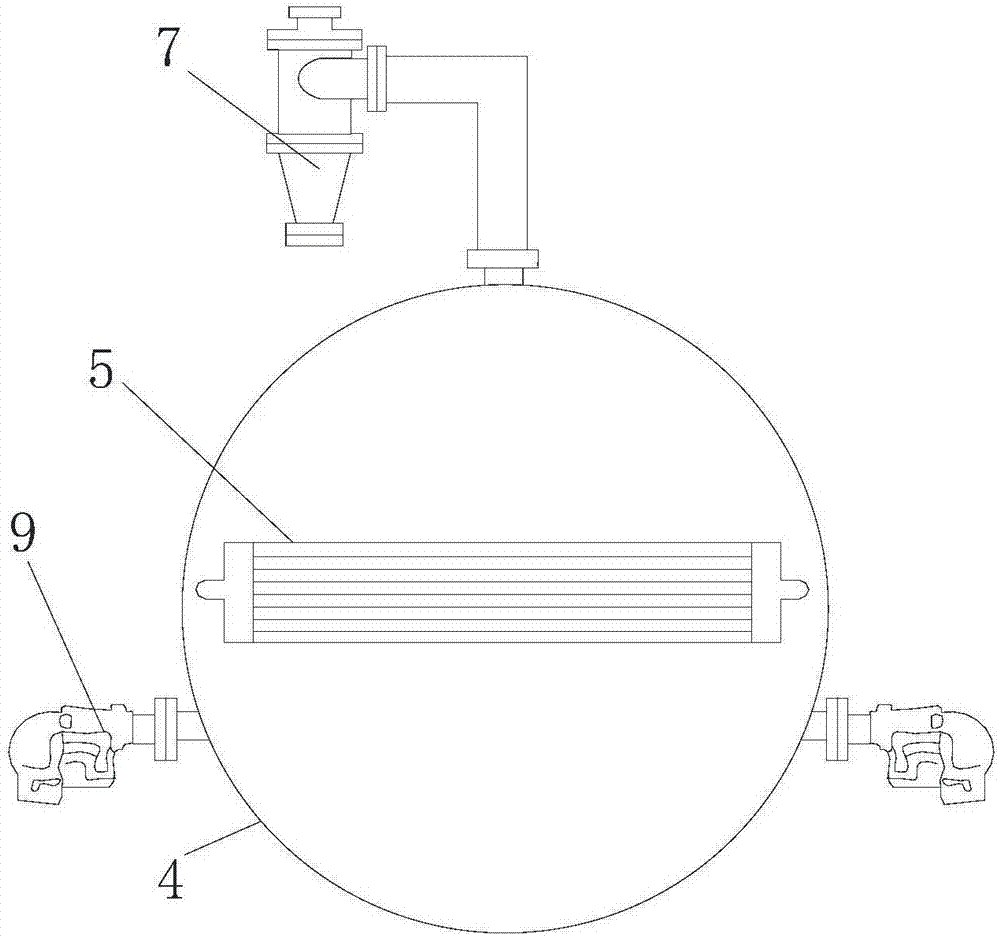

[0075] Such as figure 1 As shown, the difference between Embodiment 2 and Embodiment 1 is that the regenerative heating separation device also includes a second heating device 4, a second heat storage device 5 and a second driving device, and the second heating device 4 is arranged in the dry distillation device 1 On the right side, the second heat storage device 5 is a closed ring structure, one end of the second heat storage device 5 is located in the second heating device 4, the other end of the second heat storage device 5 is located in the carbonization device 1, and the first heat storage device 3 The ends of the second heat storage device 5 located in the carbonization device 1 are located at opposite ends, and the second drive device is connected to the second heat storage device 5 to drive the second heat storage device 5 clockwise or Rotating counterclockwise, a combined sealing device 33 is provided between the second heating device 4 and the carbonization device 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com