Soil body cutting device for shield tunneling machine and application method of soil body cutting device

A technology of a cutting device and an application method, which is applied in the field of shield machines, can solve problems such as weak soil cutting ability, offset between the construction axis and the design axis, and a small amount of tools, so as to enhance the ability of cutting strata and prevent deviation. The effect of reducing the shifting phenomenon and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

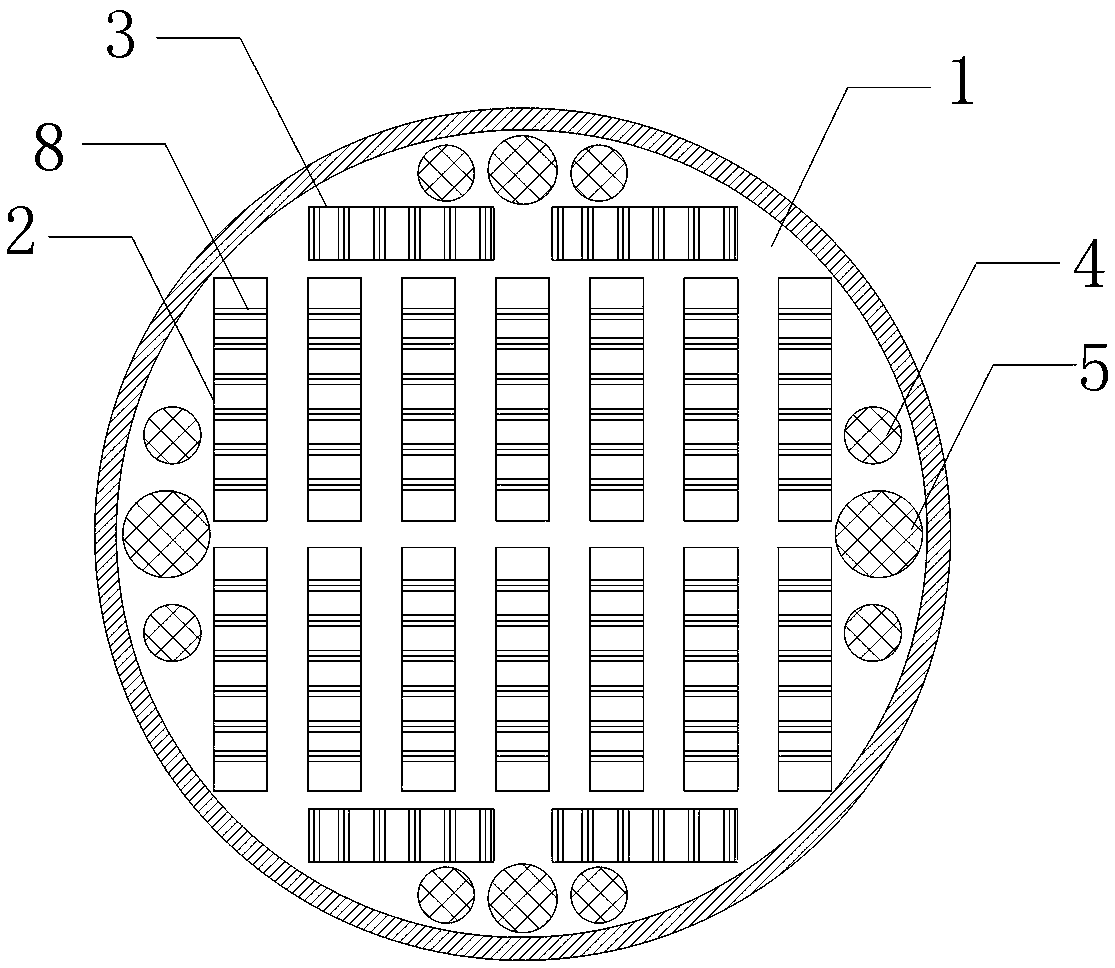

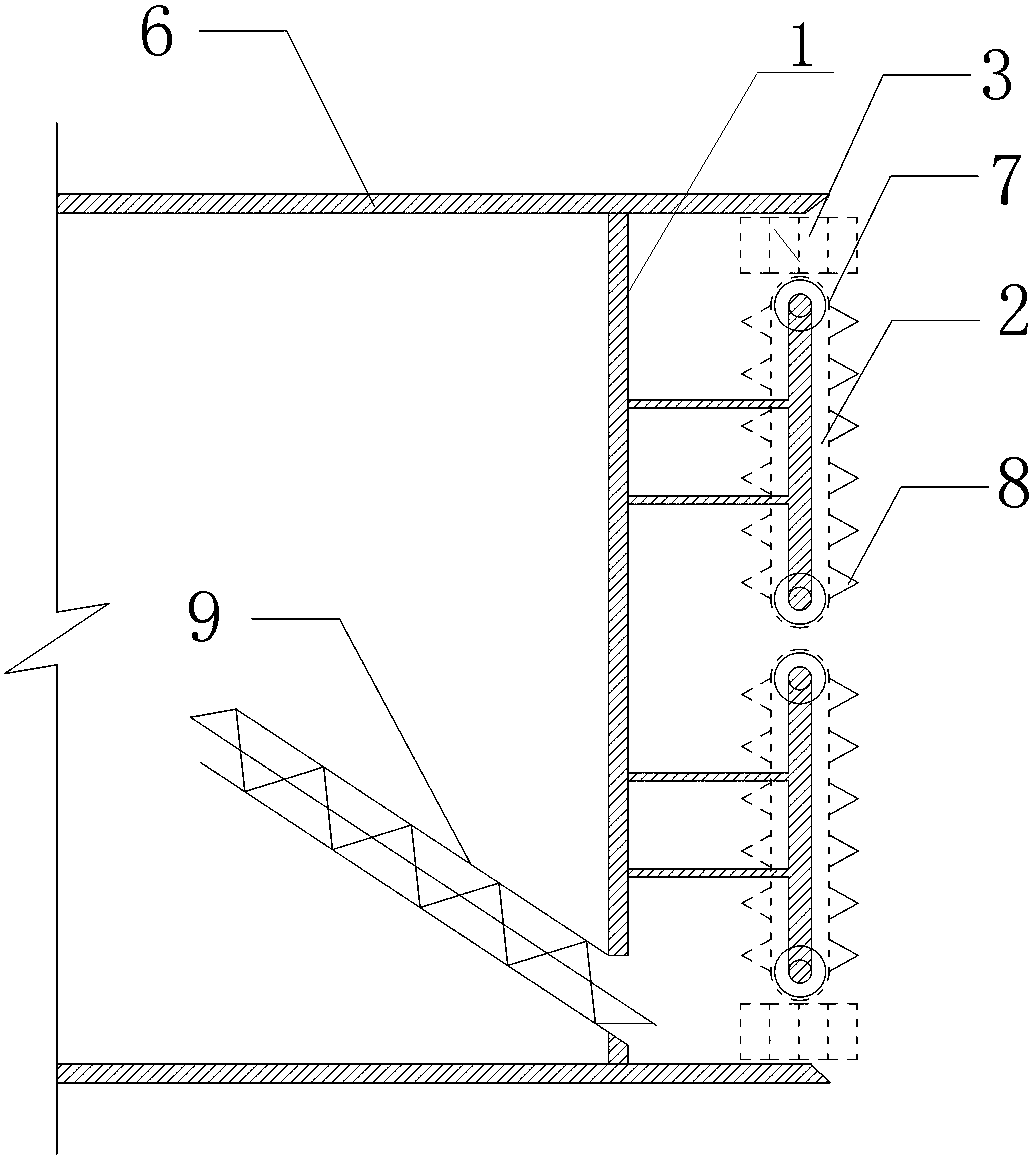

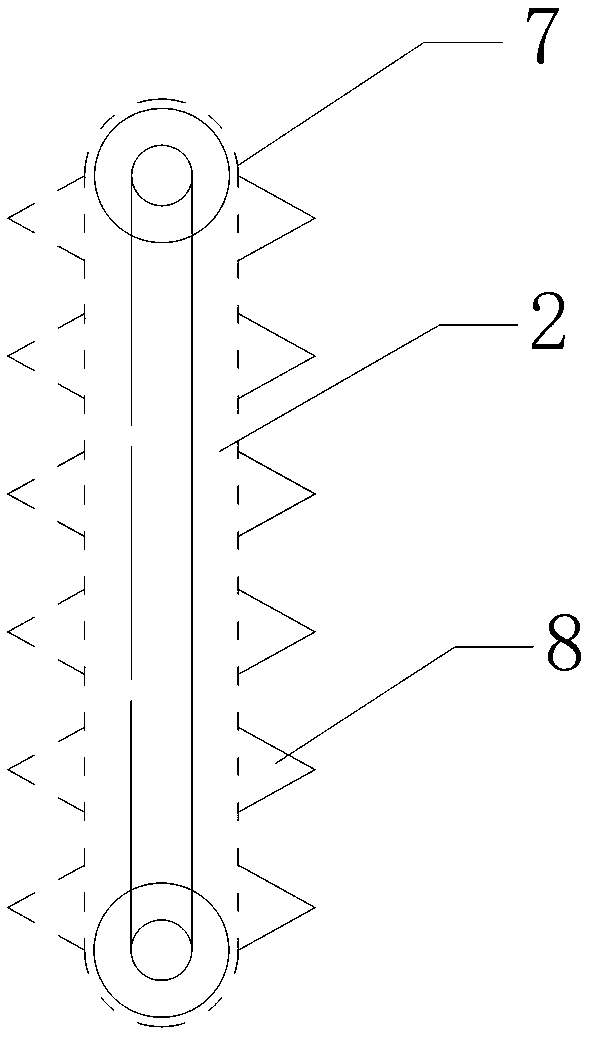

[0023] Example: such as Figure 1-3 As shown, this embodiment specifically relates to a shield machine soil cutting device and its application method. The soil cutting device is arranged on the soil bulkhead 1 at the front end of the shield machine, and includes a vertical knife chain 2, a transverse The knife chain 3 , the small rotating cutter head 4 and the small rotating cutter head 5 realize the control of the tunneling posture of the shield machine by controlling the rotation directions of the vertical knife chain 2 and the horizontal knife chain 3 .

[0024] Such as Figure 1-3 As shown, the front end of the shield shell 6 of the shield machine in this embodiment is a soil cabin, and the soil cutting device is specifically provided on the soil bulkhead 1 at the front end of the soil cabin, including a vertical knife chain 2 and a horizontal knife chain 3 , rotating small cutterhead 4, rotating small cutterhead 5. The vertical knife chains 2 are arranged in the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com