Ceramic tile seam repairing device with positioning performance for indoor decoration

A technology for interior decoration and positioning device, applied in construction, building structure and other directions, can solve the problems of operator arm soreness, inability to guarantee accuracy, and high operator requirements, so as to reduce the occupation area and reduce the difficulty of manual operation. , to ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

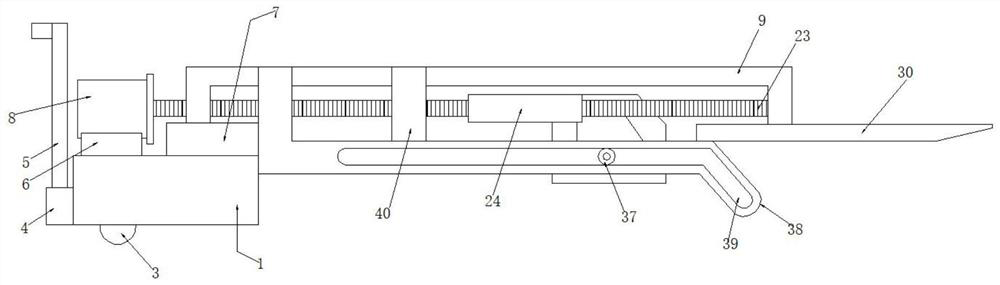

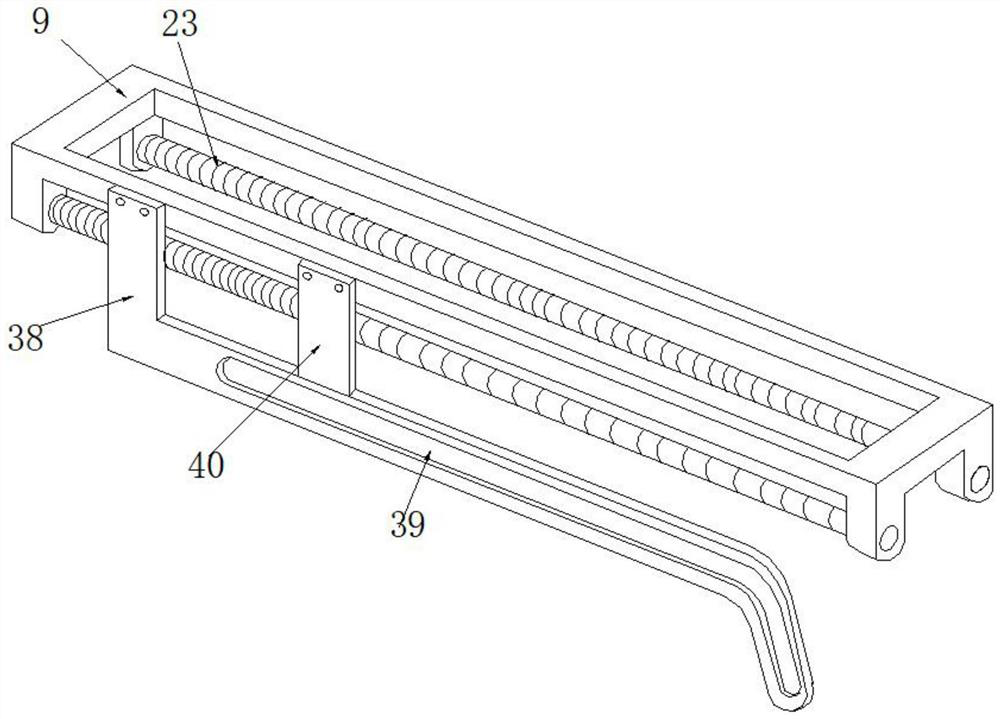

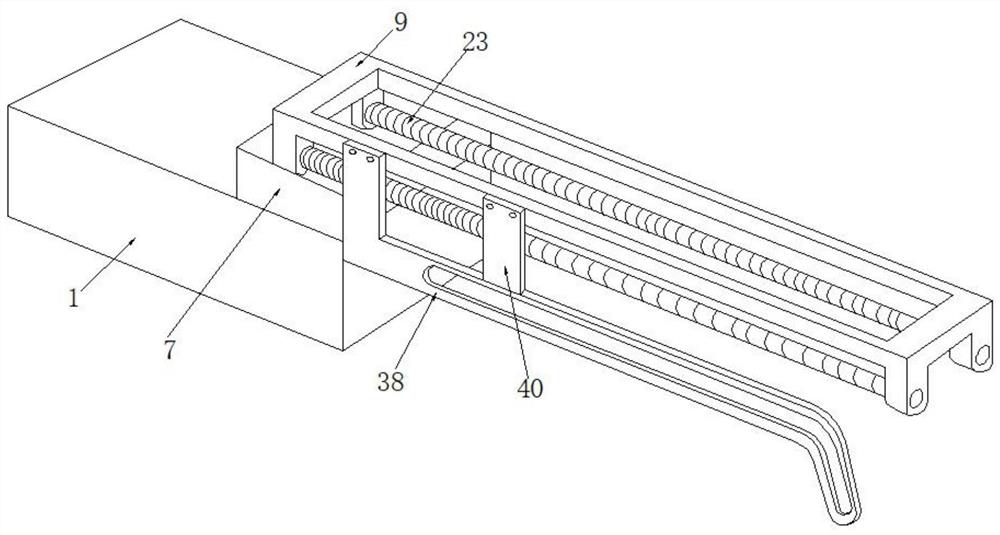

[0035] Such as figure 1 and Figure 6-8 displayed in:

[0036] The present invention provides a positioning tile seam repairing device for indoor decoration, the structure of which includes a support platform 1, and both sides of the bottom front end of the support platform 1 are provided with a groove-2, and the groove-2 All are provided with moving wheel 3 inside, described support platform 1 outer bottom center is provided with projection 4, and described projection 4 is provided with positioning device, and push rod 5 is installed on the described positioning device, and described support platform The top of 1 is provided with mounting plate 6 and fixed column 7 successively from left to right, and driver 8 is installed on described mounting plate 6, and the top of described fixed column 7 is provided with frame 9, and the four faces of described frame 9 are As a U-shaped structure, the frame 9 is provided with a seam repairing mechanism, wherein the driver 8 is electric...

Embodiment 2

[0040] Such as Figure 1-5 displayed in:

[0041] The present invention provides a positioning tile seam repairing device for indoor decoration, the structure of which includes a support platform 1, and both sides of the bottom front end of the support platform 1 are provided with a groove-2, and the groove-2 All are provided with moving wheel 3 inside, described support platform 1 outer bottom center is provided with projection 4, and described projection 4 is provided with positioning device, and push rod 5 is installed on the described positioning device, and described support platform The top of 1 is provided with mounting plate 6 and fixed column 7 successively from left to right, and driver 8 is installed on described mounting plate 6, and the top of described fixed column 7 is provided with frame 9, and the four faces of described frame 9 are As a U-shaped structure, the frame 9 is provided with a seam repairing mechanism, wherein the driver 8 is electrically connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com