Emulsifying method and device by double-vortex-body vortex

A double vortex and vortex technology, applied in the field of double vortex vortex emulsification, can solve the problems of poor emulsification effect and complicated device structure, and achieve the effect of easy implementation and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

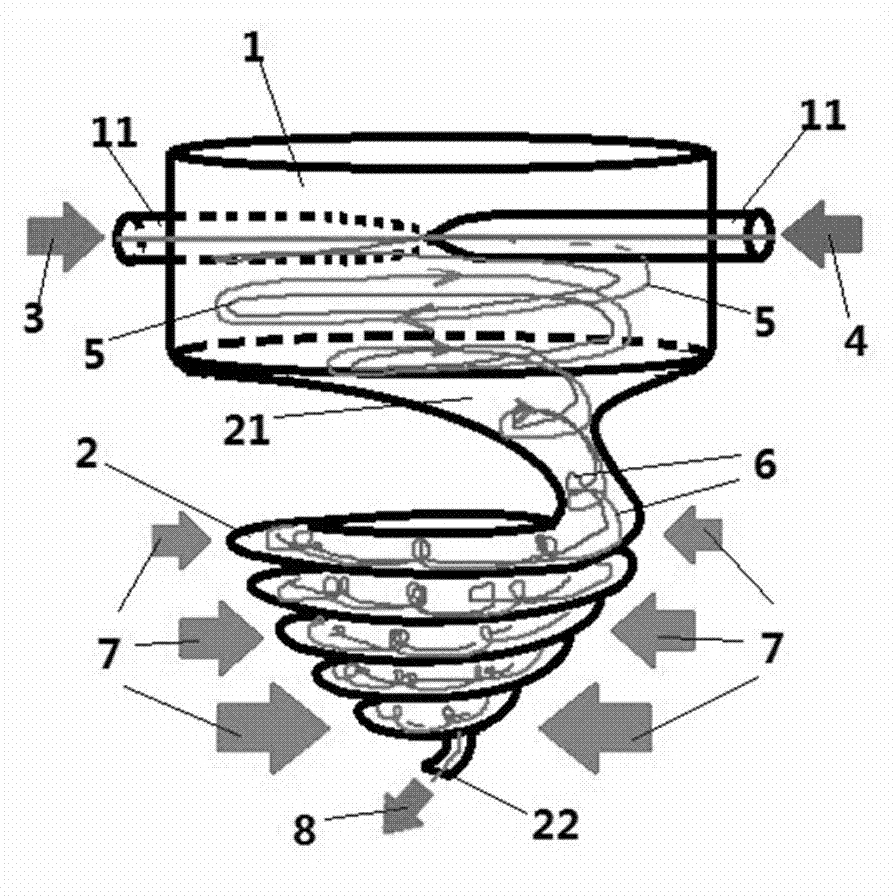

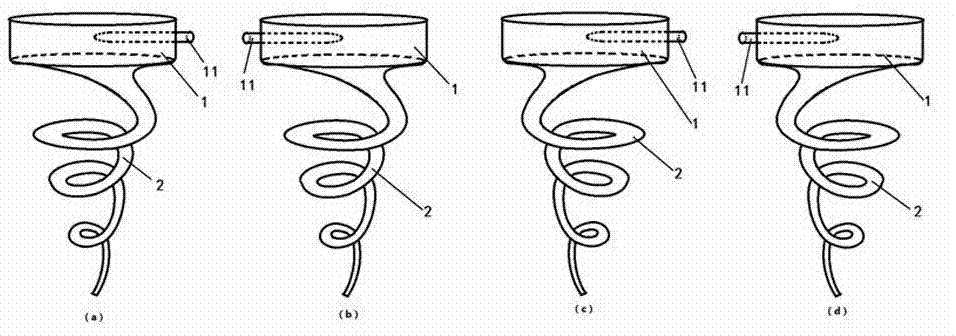

[0028] see Figure 1-Figure 3 , the present invention is a kind of double-scroll body vortex emulsification method, it is characterized in that one or more material fluids to be emulsified, such as various oils, fats, creams, powders, etc., are mixed with another fluid (such as Water) flows through a double vortex vortex generating device and then makes a double vortex centripetal vortex motion and then is discharged from the lower end to form an emulsion 8 .

[0029] The double-scroll vortex generating device includes: a main body container 1 and a double-scroll vortex tube 2 .

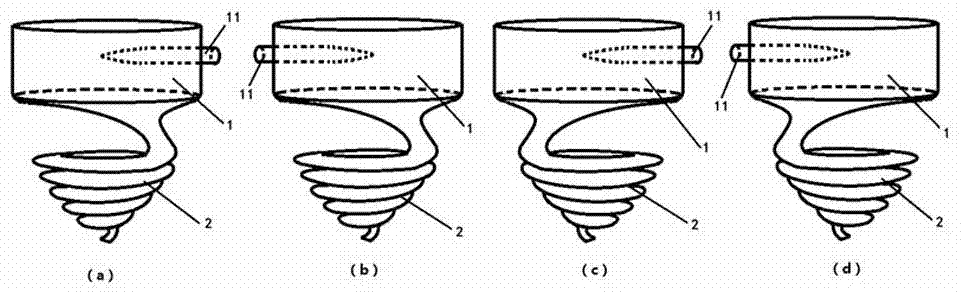

[0030] The cross-section of the main container 1 is circular, and more than one side feeding port 11 with the same tangential direction is provided on its circumference, and two or more feeding ports 11 can be uniformly distributed along the circumference, or can be other distribution method. More than two side feed ports 11 can be distributed on the same horizontal height of the main body containe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com