Automatic conveying device for various kinds of rivets

An automatic conveying device and rivet technology, applied in the field of automatic processing, can solve the problems of complex structure, limited scope of application, inability to apply, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

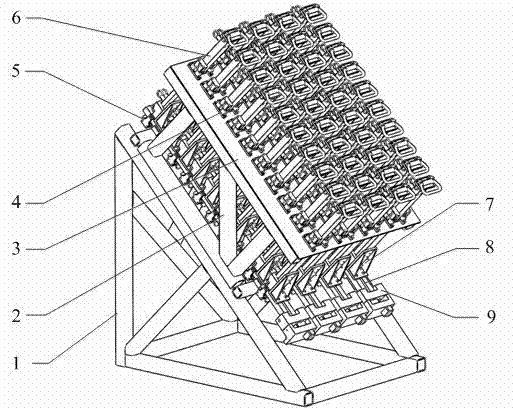

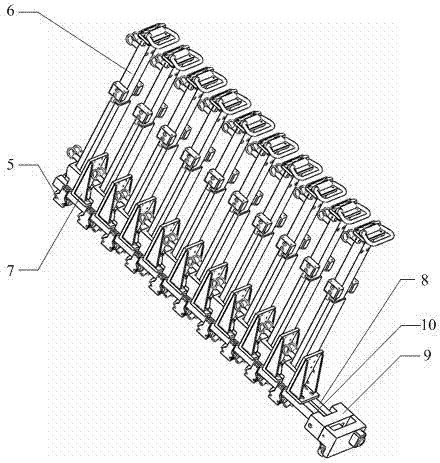

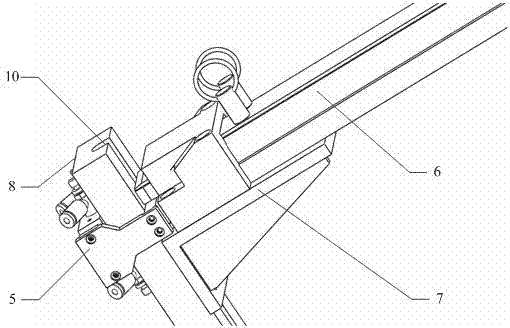

[0025] Such as figure 1 As shown, the present invention comprises inclined base support 1, side support 2, cover plate 3, base plate 8 and nail clip 6, wherein, several base plates 8 are housed on the inclined surface of base support 1, and base support 1 is installed by side support 2. There is a cover plate 3 parallel to the bottom plate 8, on which there are buckle groups 4 distributed in an array, several nail clips 6 equipped with different rivets are inserted into the buckle group 4, and are installed on the bottom plate 8 through the nail clip support frame 7 On the upper surface of each bottom plate 8 there is a trough 10, between each nail clip 6 and the bottom plate 8, a material spacer 5 is installed, and the end of the bottom plate 8 is connected with the nail blowing assembly 9.

[0026] A rivet of one specification is placed in each nail clip 6 , rivets with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com