Four-dimensional (4D) rapid molding machine capable of having wired and wireless communications with multiple targets

A wireless communication and wired communication technology, applied in the field of 4D rapid prototyping machines, can solve the problems of inability to achieve bidirectional feedback and control, inability to one-to-many or many-to-one, and inability to transmit data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

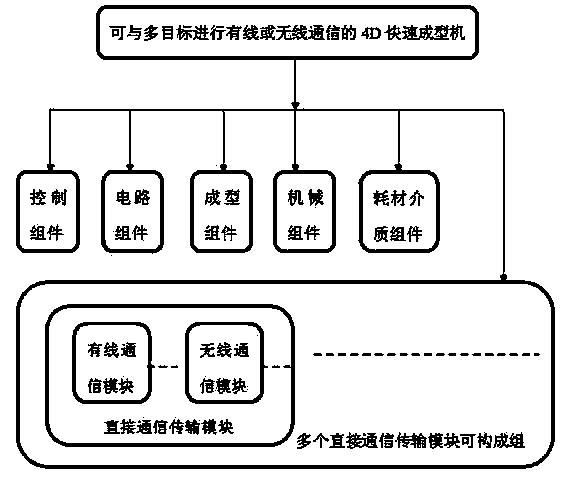

[0041] figure 1 It is a structural block diagram of the 4D rapid prototyping machine capable of wired and wireless communication with multiple targets in the present invention.

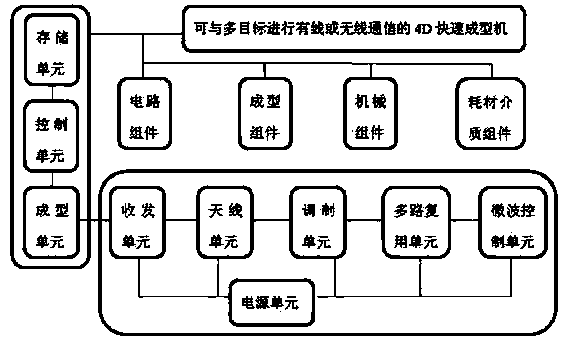

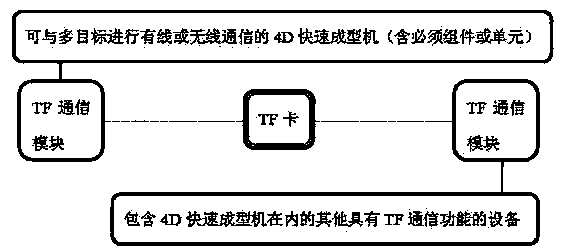

[0042] A 4D rapid prototyping machine capable of wired and wireless communication with multiple targets, including a forming machine control component, a circuit component, a molding component, a mechanical component, and a consumable media component, characterized in that: in the 4D rapid prototyping machine, there are also Direct communication transmission module. The direct communication transmission module has a wireless communication module and a wired communication module, or only one of the two types. The wireless or wired communication module can transmit instructions or model data one-way or two-way. The direct communication transmission module can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com