An energy-saving and environment-friendly aerosol can lid conveying device

An energy-saving and environment-friendly transmission device technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of high power consumption, affecting quality and speed, and low efficiency, so as to shorten the transmission line, save power, and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

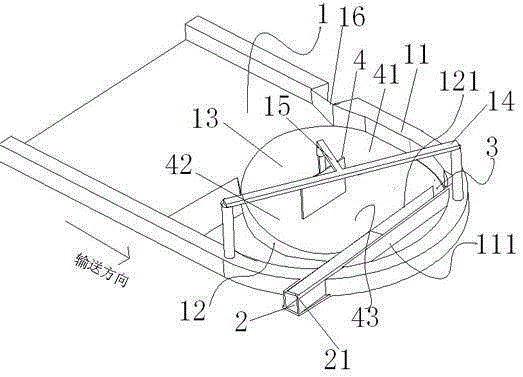

[0018] An energy-saving and environment-friendly aerosol can lid conveying device provided by the present invention, as attached figure 1 Said: including the platform 1 welded and supported by the supporting feet, the first side plate 11 welded on the platform 1, the second side plate 12 and the circular turntable 13 installed in the middle of the platform 1, the A rotating shaft is welded below the rotating disk 13, and there is a groove for installing a motor belt on the rotating shaft, the motor is connected by the motor belt, and the rotating disk 13 is driven by the motor to rotate; the end of the first side plate 11 near the rotating disk 13 is provided with a first End plate 111, the end of the second side plate 12 close to the turntable 13 is provided with a second end plate 121, and the end of the first side plate 11 away from the second end plate 121 is provided with a raised plate 16 , the raised plate 16 forms an included angle of 45-60° with the conveying directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com