Aerial work platform

A high-altitude work platform and work platform technology, applied in the direction of lifting device, lifting frame, etc., can solve the problems of paint damage on the surface of the car body, prone to accidents, platform drop, etc., to improve the safe work area, ensure platform safety, and overall simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

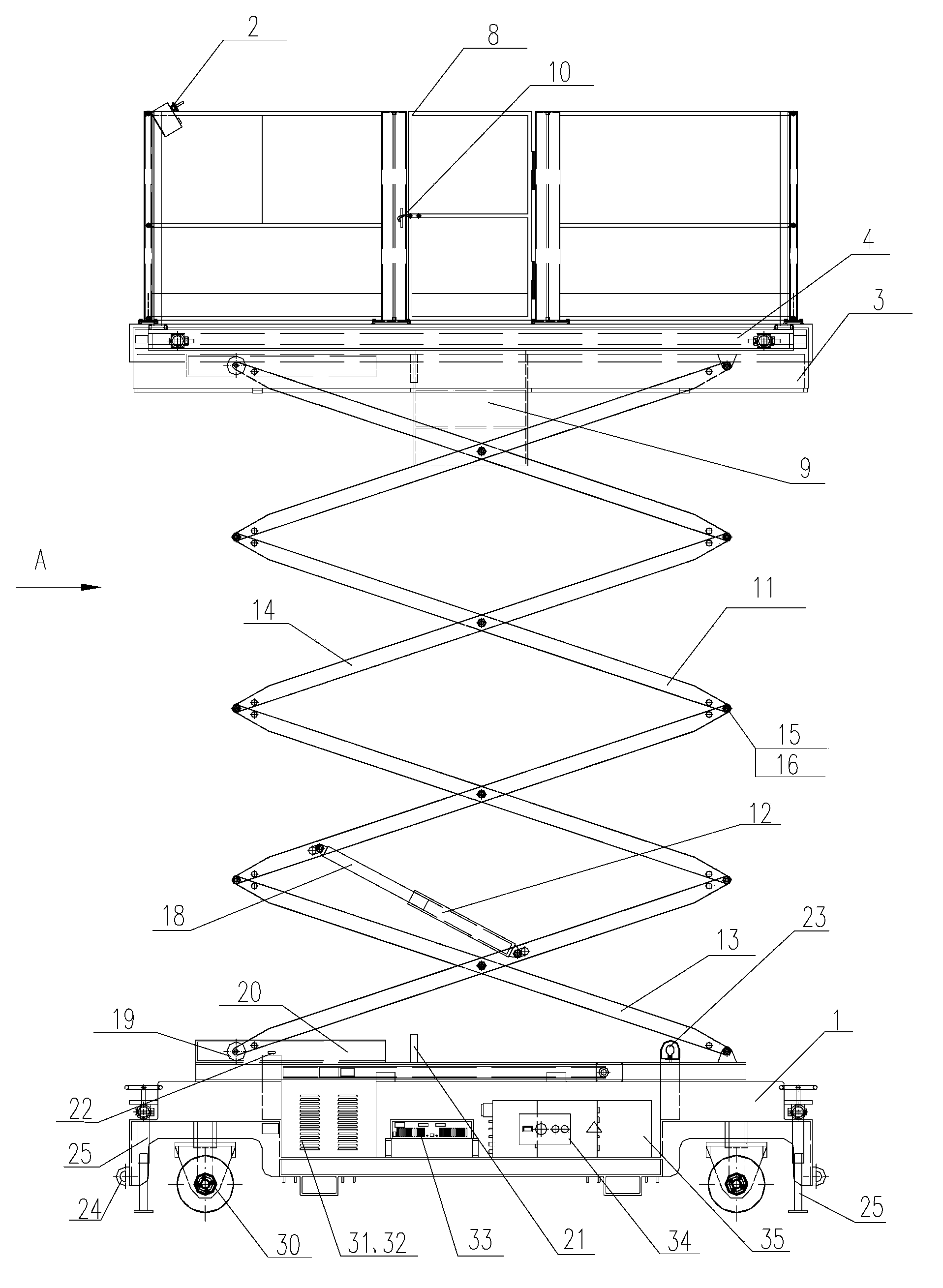

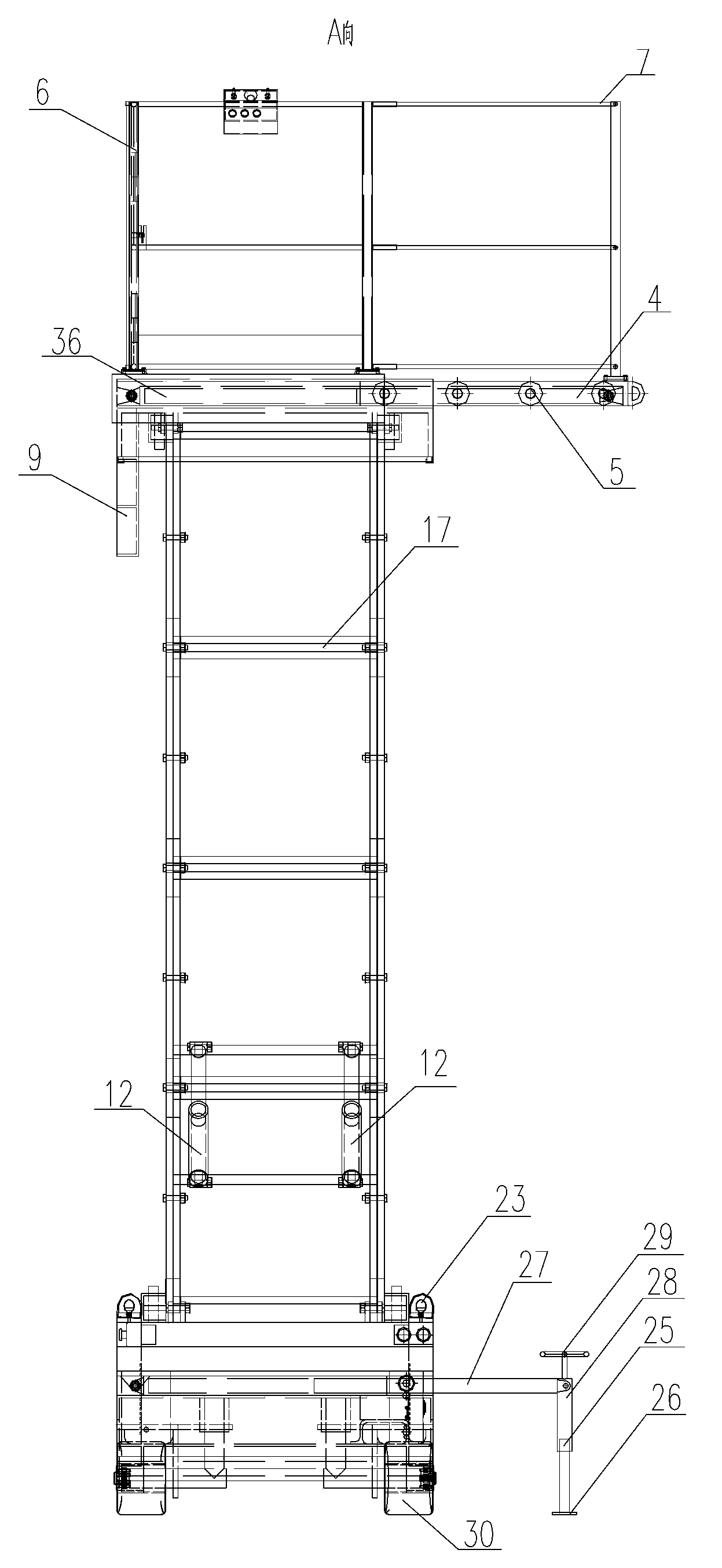

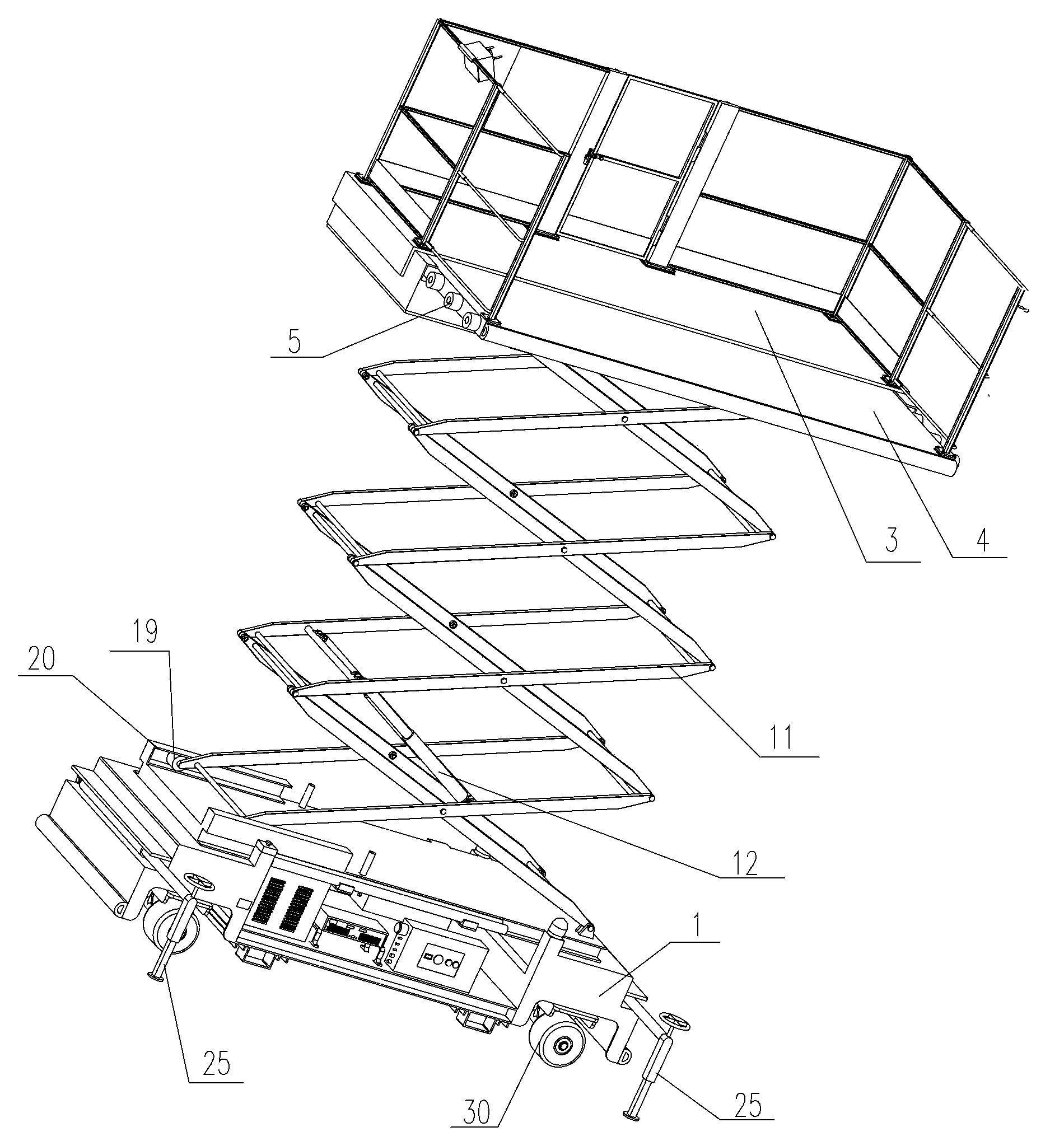

[0026] Such as Figure 1 to Figure 3 As shown, an aerial work platform is used for locomotive roof assembly, including a platform chassis 1 , a traveling device, a lifting device, a working platform and a control unit 33 .

[0027] The control unit 33 controls the movement of the walking device, the lifting of the lifting device and the expansion and contraction of the work platform. The control unit 33 is connected to an operable control panel 2. The control panel 2 is arranged on the work platform to facilitate construction personnel to operate the control panel 2. The control unit 33 also has a remote controller, through the sending and receiving of remote control signals, realizes the remote control to walking gear, hoisting gear and work platform, makes the operation simpler and more convenient.

[0028] The operating platform includes a fixed platform 3 and a mobile platform 4, and the mobile platform 4 is arranged on the fixed platform 3. In order to ensure that the mob...

Embodiment 2

[0047] The difference from Embodiment 1 is that two mobile platforms 4 are arranged on the fixed platform 3, which are respectively telescopic in two directions forward and backward. The platform power transmission mechanism 36 adopts a bidirectional telescopic mechanism, and the piston rods on both sides of the bidirectional telescopic mechanism respectively It is fixedly connected with the two mobile platforms 4, and four platform power transmission mechanisms 36 can also be used. The bottom of each mobile platform 4 is fixedly connected with two platform power transmission mechanisms 36 to realize bidirectional expansion and contraction.

[0048] In order to avoid rollover accidents and ensure safe operation, in this embodiment, there are four ground support feet 25, and one ground support foot 25 is set at the four corners of the platform chassis 1. According to the telescopic direction of the mobile platform 4, the control phase The two ground legs 25 on the corresponding ...

Embodiment 3

[0050] The difference from Embodiment 1 is that the X-shaped scissor arm 11 can slide to both sides, and the bottommost first-stage inner scissor member 13 and first-stage outer scissor member 14 are all slidably connected to the platform chassis 1 A roller 19 is provided at the ends of the first-stage inner scissor member 13 and the first-stage outer scissor member 14, and a guide groove 20 is provided on the upper surface of the platform chassis 1. When the X-shaped scissor arm 11 is on When lifting under the drive of the lifting power hydraulic cylinder 12, the roller 19 slides in the guide groove 20. Both the top end of the top fourth-level inner scissor member 13 and the top end of the fourth-level outer scissor member 14 can be slidably connected to the lower surface of the fixed platform 3. The structure of the sliding connection is the same as above, and the guide groove 20 is fixed on the lower surface of the fixed platform 3, thereby ensuring the continuity and stabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com