Brick and manufacturing method thereof

A production method and slurry technology, applied in the manufacturing field, can solve problems such as waste of resources, and achieve the effect of overcoming waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] An embodiment of the present invention provides a brick, whose raw material components include 7.5-8.0 parts of waste slag powder, 1.6-1.8 parts of cement and 0.4-0.5 parts of water in parts by weight.

[0014] The brick provided by the invention uses the waste slag powder formed after burning the woody slag produced in the fiberboard production process as one of the components to form brick components together with cement and water, and then realizes the effect of reusing the waste slag powder The invention overcomes the defect of waste of resources caused by direct discarding of waste slag powder in the related art.

[0015] Preferably, in this embodiment, in parts by weight, the raw material components include 7.7-7.9 parts of waste residue powder, 1.6-1.7 parts of cement and 0.45-0.5 parts of water. The bricks made according to the above-mentioned preferred ratio have a dense surface and are not easy to be damaged.

[0016] In addition, in order to mix the waste sl...

Embodiment 2

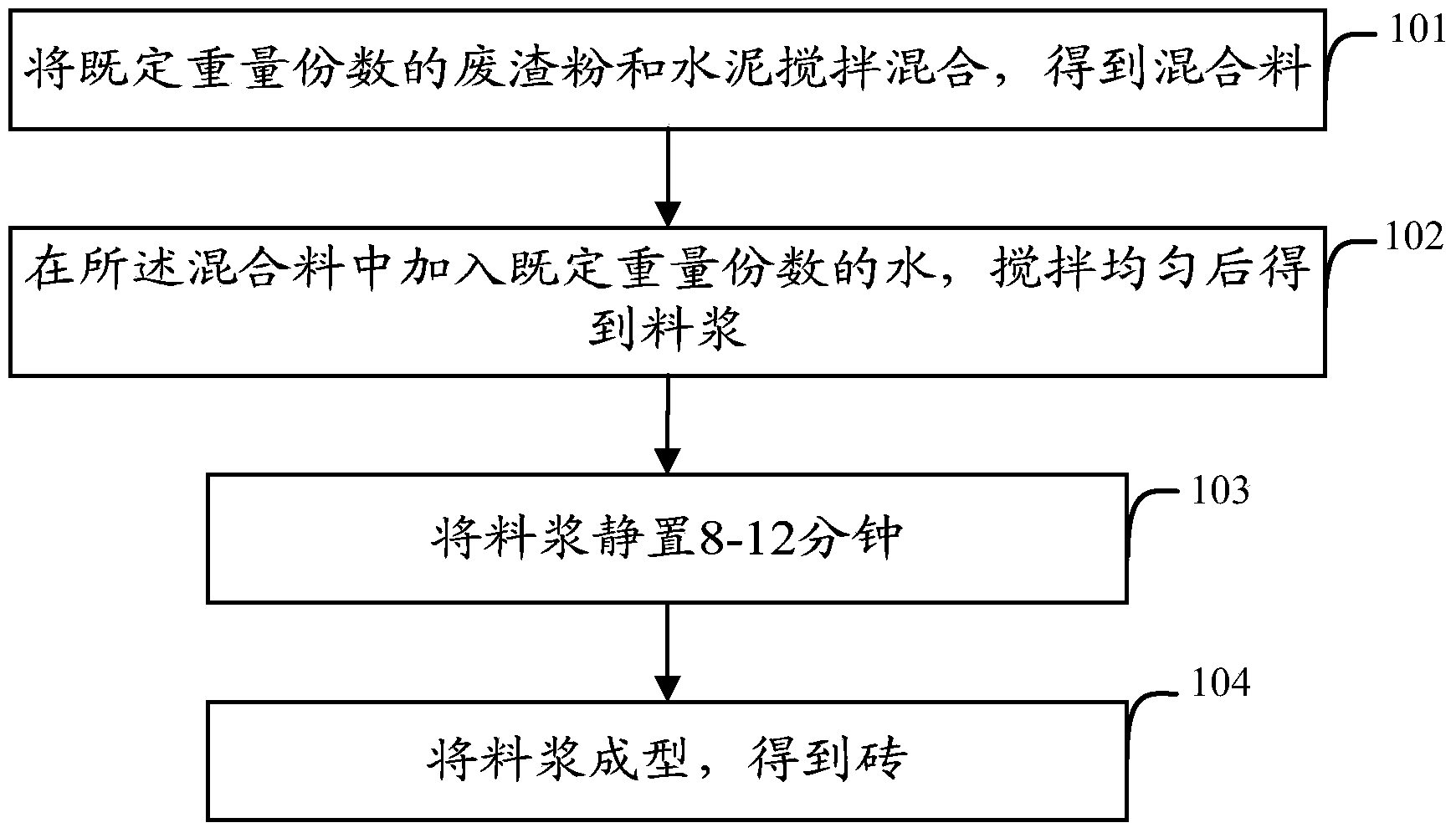

[0020] In this embodiment, the manufacturing method of the brick provided in the first embodiment specifically includes the following steps:

[0021] Step 101: Stir and mix waste residue powder and cement in predetermined parts by weight to obtain a mixture;

[0022] In step 101, specifically, in order to ensure the compressive strength of the bricks produced, it is necessary to mix the waste slag powder and cement as much as possible. Therefore, in this embodiment, preferably, the stirring and mixing time is 10-20 minutes.

[0023] Step 102: Adding predetermined weight parts of water into the mixture, stirring evenly to obtain a slurry.

[0024] Specifically, step 102 can be implemented according to the following method: the mixture is added to the blender, and then water of a predetermined weight part is added to the mixture, and the slurry is obtained after being uniformly stirred by the blender; the blender can mix well Material and mixing to obtain a slurry.

[0025] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com