Environment-friendly water-based op protective coating composition and its preparation and use

A technology for protecting coatings and compositions, applied in polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of high drying temperature, high oxidation resistance, slow curing speed, etc., and achieve good storage stability , The effect of low application cost and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

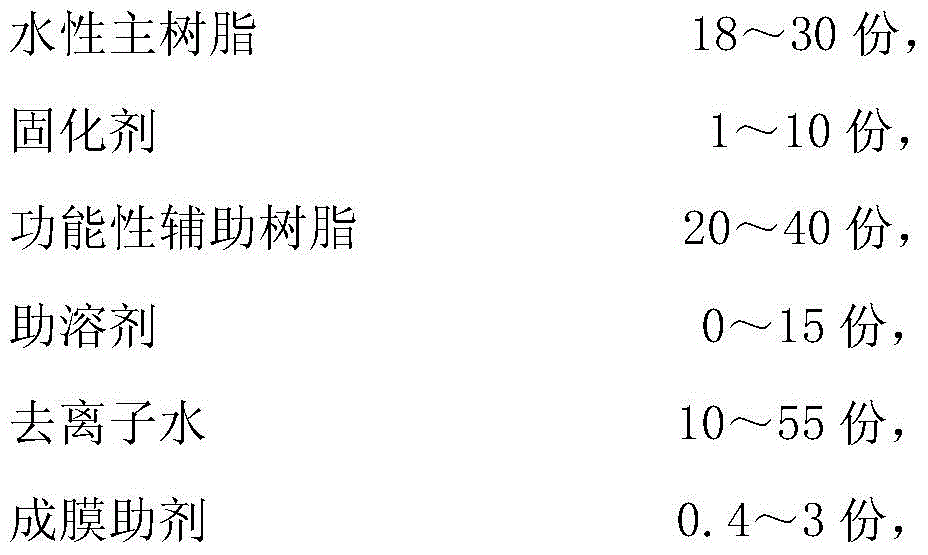

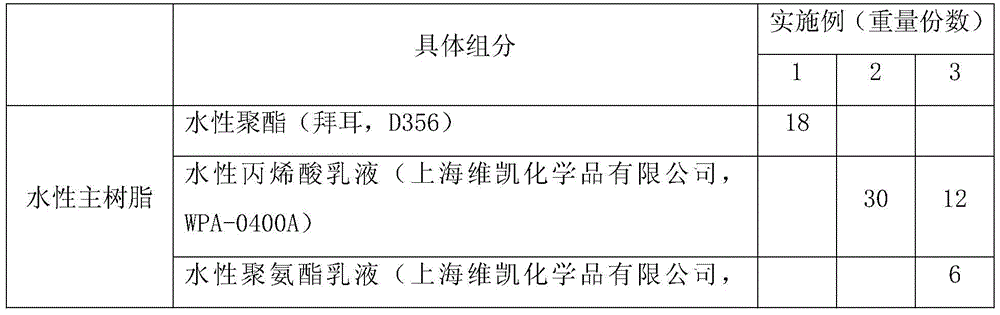

[0033] The environment-friendly water-based OP protective coating composition of the present embodiment includes the components and parts by weight shown in Table 1. Its preparation method comprises the following steps:

[0034] (1) according to each component shown in table 1 and content (weight part) prepare raw materials:

[0035] (2) Put the water-based main resin, functional auxiliary resin, and curing agent into the reaction kettle, and stir at a low speed of 400 rpm for 10 minutes to make the mixture even;

[0036] (3) After mixing the co-solvent, deionized water, and film-forming aids evenly, add them to the reaction kettle while stirring, and stir at a low speed of 400 rpm for 10 minutes to make the mixture even;

[0037] (4) Add a wetting agent and a pH regulator to the reaction kettle in sequence, and stir at a medium speed of 700 rpm for 15 minutes;

[0038] (5) Add a defoamer into the reaction kettle, and stir at a high speed of 1200 rpm for 40 minutes to obtain...

Embodiment 2

[0042] The environment-friendly water-based OP protective coating composition of the present embodiment includes the components and parts by weight shown in Table 1. Its preparation method comprises the following steps:

[0043] (1) according to each component shown in table 1 and content (weight part) prepare raw materials:

[0044] (2) Put the water-based main resin, functional auxiliary resin, and curing agent into the reaction kettle in sequence, and stir at a low speed of 400 rpm for 5 minutes to make the mixture even;

[0045] (3) After mixing the co-solvent, deionized water, and film-forming aids evenly, add them into the reaction kettle while stirring, and stir at a low speed of 400 rpm for 20 minutes to make the mixture even;

[0046] (4) Add a wetting agent and a pH regulator into the reaction kettle, and stir at a medium speed of 600 rpm for 10 minutes;

[0047] (5) Add a defoamer into the reaction kettle, and stir at a high speed of 1000 rpm for 30 minutes to obt...

Embodiment 3

[0051] The environment-friendly water-based OP protective coating composition of the present embodiment includes the components and parts by weight shown in Table 1. Its preparation method comprises the following steps:

[0052] (1) according to each component shown in table 1 and content (weight part) prepare raw materials:

[0053] (2) Put the water-based main resin, functional auxiliary resin, and curing agent into the reaction kettle, and stir at a low speed of 450 rpm for 7 minutes to make the mixture even;

[0054] (3) After mixing deionized water and film-forming aids evenly, add them to the reaction kettle while stirring, and stir at a low speed of 450 rpm for 15 minutes to make the mixture even;

[0055](4) Add a wetting agent and a pH regulator into the reaction kettle, and stir at a medium speed of 800 rpm for 20 minutes;

[0056] (5) Add a defoamer into the reaction kettle, and stir at a high speed of 900 rpm for 35 minutes to obtain an environmentally friendly w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com