Water-based environmental protection coating for ink resident direct plating beer label and preparation method thereof

An environmentally friendly coating and beer labeling technology, applied in the field of water-based coatings, can solve the problems of damaging the atmospheric environment, the aluminum layer is not easy to be washed off, and human health and safety hazards. It achieves convenient construction, excellent ink retention and leveling effects, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

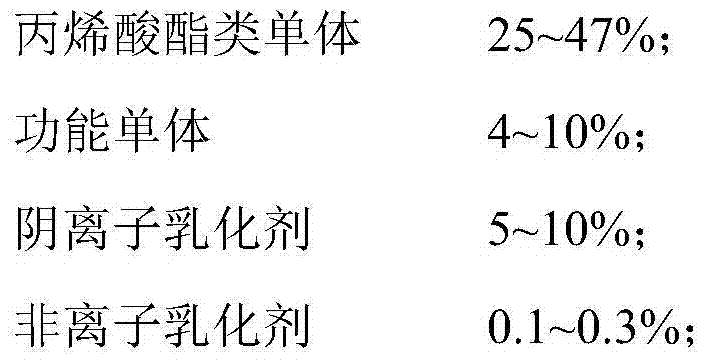

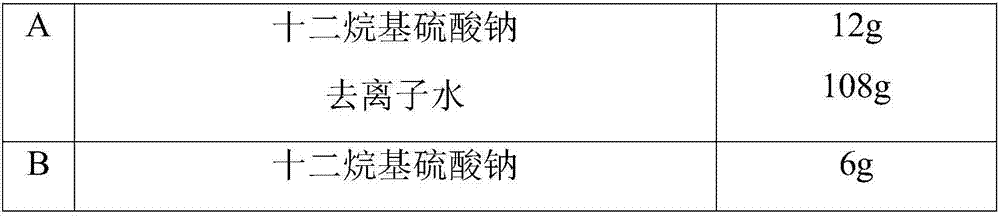

[0032] The acrylic emulsion of this embodiment is prepared using the raw materials of the following components and contents:

[0033]

[0034]

[0035] The above-mentioned aqueous acrylic acid emulsion is prepared according to the following process steps:

[0036] (1) Adopt pre-emulsified semi-continuous seed emulsion polymerization method:

[0037] 1. After rinsing the pre-emulsification tank, turn on the stirring at 800rpm to stir and disperse part of the pre-emulsion liquid and deionized water component B evenly.

[0038] 2. Then add the monomer C component of the formula amount and stir quickly for pre-emulsification, and set aside. Then keep the rotation speed at 250rpm, take out 10g as a seed, and add the initiator D component.

[0039] 3. Add deionized water and the remaining emulsifier A component into the reaction kettle, stir and heat up to 80°C, add initiator E to the base material for initiation, keep it warm for 5 minutes, add 10g of seed emulsion and keep...

Embodiment 2

[0045] The acrylic emulsion of this embodiment is prepared using the raw materials of the following components and contents:

[0046]

[0047] The above-mentioned aqueous acrylic acid emulsion is prepared according to the following process steps:

[0048] (1) Adopt pre-emulsified semi-continuous seed emulsion polymerization method:

[0049] 1. After rinsing the pre-emulsification tank, turn on the stirring at 800rpm to stir and disperse part of the pre-emulsion liquid and deionized water component B evenly.

[0050] 2. Then add the monomer C component of the formula amount and stir quickly for pre-emulsification, and set aside. Then keep the rotation speed at 250rpm, take out 10g as a seed, and add the initiator D component.

[0051] 3. Add deionized water and the remaining emulsifier A component into the reaction kettle, stir and heat up to 80°C, add initiator E to the base material for initiation, keep it warm for 5 minutes, add 10g of seed emulsion and keep it warm for...

Embodiment 3

[0056] The acrylic emulsion of this embodiment is prepared using the raw materials of the following components and contents:

[0057]

[0058]

[0059] The above-mentioned aqueous acrylic acid emulsion is prepared according to the following process steps:

[0060] (1) Adopt pre-emulsified semi-continuous seed emulsion polymerization method:

[0061] 1. After rinsing the pre-emulsification tank, turn on the stirring at 800rpm to stir and disperse part of the pre-emulsion liquid and deionized water component B evenly.

[0062] 2. Then add the monomer C component of the formula amount and stir quickly for pre-emulsification, and set aside. Then keep the rotation speed at 250rpm, take out 10g as a seed, and add the initiator D component.

[0063] 3. Add deionized water and the remaining emulsifier A component into the reaction kettle, stir and heat up to 80°C, add initiator E to the base material for initiation, keep it warm for 5 minutes, add 10g of seed emulsion and keep i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com