Friction tongue lock body reversing structure

A technology of tongue lock and lock housing, applied in the field of reversing structure of friction tongue lock body, which can solve the problems of poor lock applicability, inability to reversing, not so beautiful, etc., to achieve reasonable structure, convenient reversing adjustment, and ensure the force The effect of strength and aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

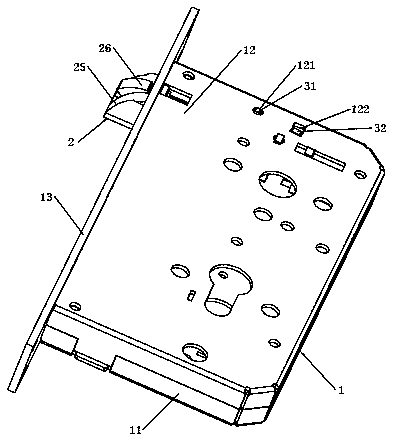

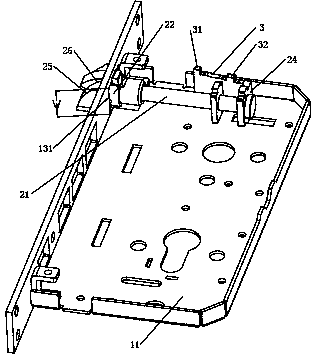

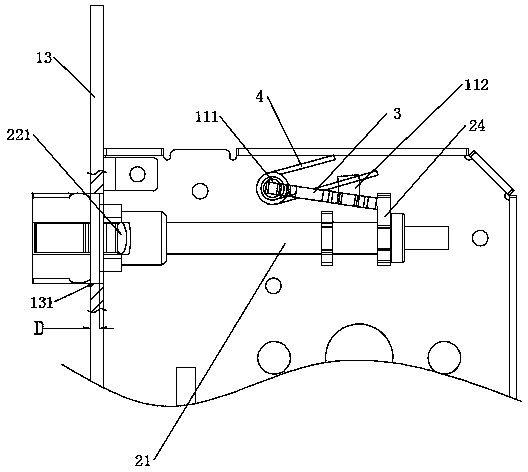

[0018] The present invention is a reversing structure of friction tongue lock body, such as Figure 1 to 3 As shown, it includes a lock housing 1 composed of a bottom plate 11, a cover plate 12, and a side plate 13, and a friction tongue assembly 2 installed in the lock housing 1. The friction tongue assembly 2 includes friction tongue rods 21, which are respectively installed The circular friction tongue seat 22, the friction tongue spring (not shown in the figure) and the friction tongue toggle block 24 on the three front, middle and rear parts of the friction tongue rod 21 are installed on the upper and lower two parts of the friction tongue seat 22. A friction tongue 25 and a friction tongue touch tongue 26 oscillatingly connected between the two friction tongues 25. These structures are basically the same as the current lock body with friction tongues. The difference is: There is a reversing control board 3 and a spring 4 that makes the reversing control board 3 always swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com