Tire walking full-hydraulic lining trolley

A lining trolley, full hydraulic technology, applied in wellbore lining, tunnel lining, underground chambers, etc., can solve problems such as damage, trolley deformation, high working environment requirements, etc., and achieve the effect of reducing labor intensity and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

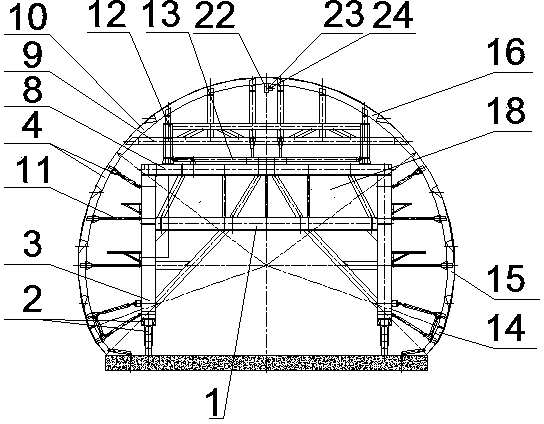

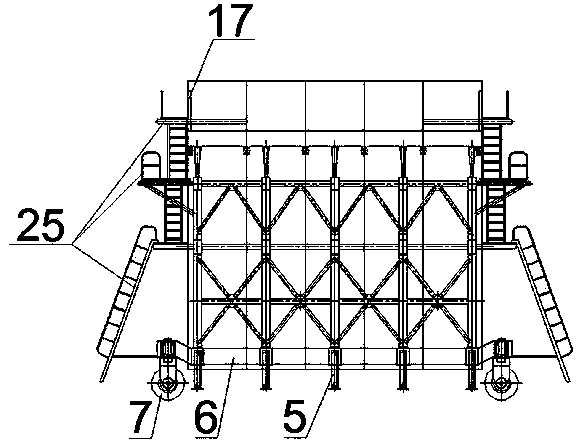

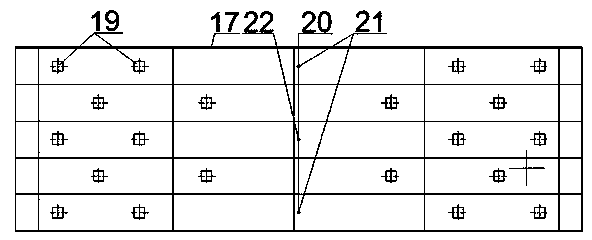

[0026] Attached below figure 1 , 2 , 3 the present invention is described in detail:

[0027] A tire-type running full hydraulic lining trolley, which includes a car body 1. According to the tunnel lining direction, there are 5 lining trolleys in total, each 1800mm, and the trolley hydraulic leveling support and running system are sequentially arranged from bottom to top according to the height direction. 2. Mast 3, formwork and hydraulic formwork adjustment system 4. The trolley hydraulic leveling support and running system 2 includes the trolley overall leveling support hydraulic cylinder 5, curved beam 6, and tire running system 7. The trolley overall leveling support hydraulic cylinder 5 has 2 groups 10 One, fixedly installed on the curved beam 6, the tire running system 7 has 2 pairs of 4, installed on the bottom of the curved beam 6, the door frame 3 has 5 pieces, including the lower bearing door Frame 8 and the upper support door frame 9, the lower support door f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com