Stress and strain measurement method of steel bar under high temperature and variable loading rate

A technology for measuring steel stress and strain, applied to measuring devices, instruments, etc., can solve the problems of steel full strain and inaccurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

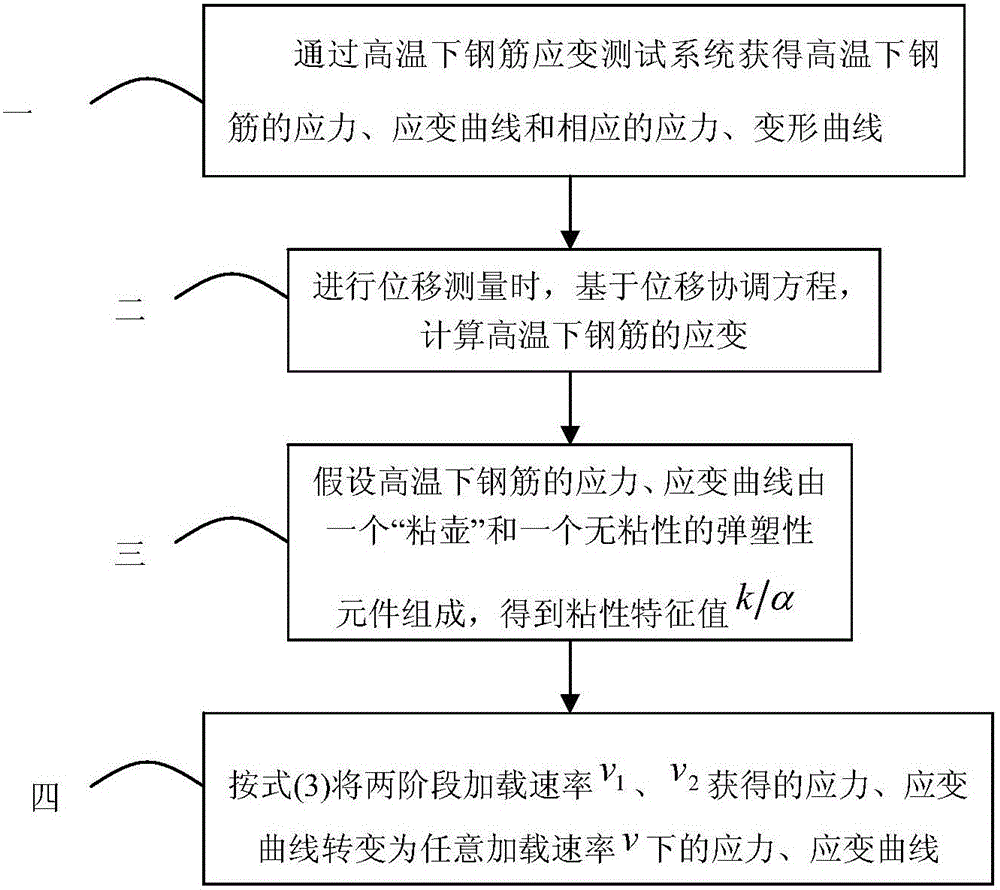

[0036] Specific implementation mode 1: The steel bar stress and strain measurement method under the high temperature variable loading rate of the present implementation mode includes the following contents:

[0037] 1. Obtain the stress and strain curves and corresponding stress and deformation curves of steel bars at high temperature through the steel bar strain test system at high temperature;

[0038] Wherein, the maximum value of strain in the stress and strain curves is ε 0 , ε 0 Less than the ultimate tensile strain of the steel bar at high temperature;

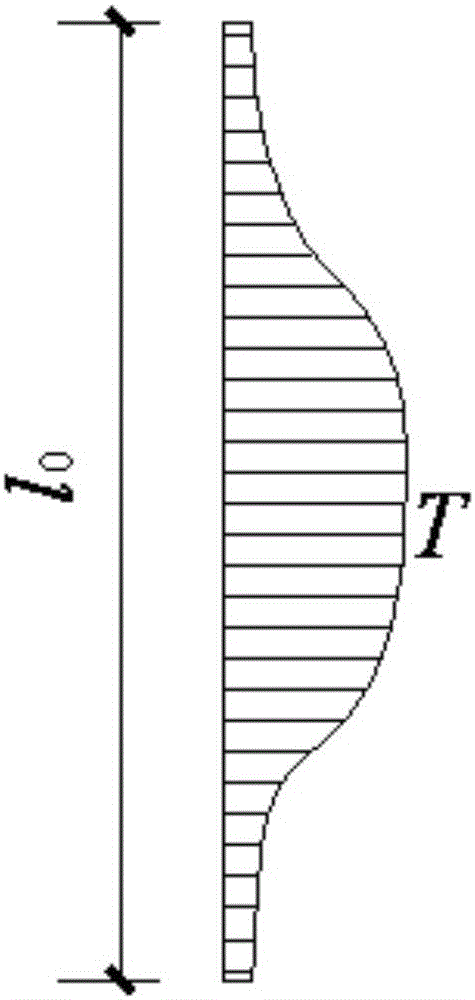

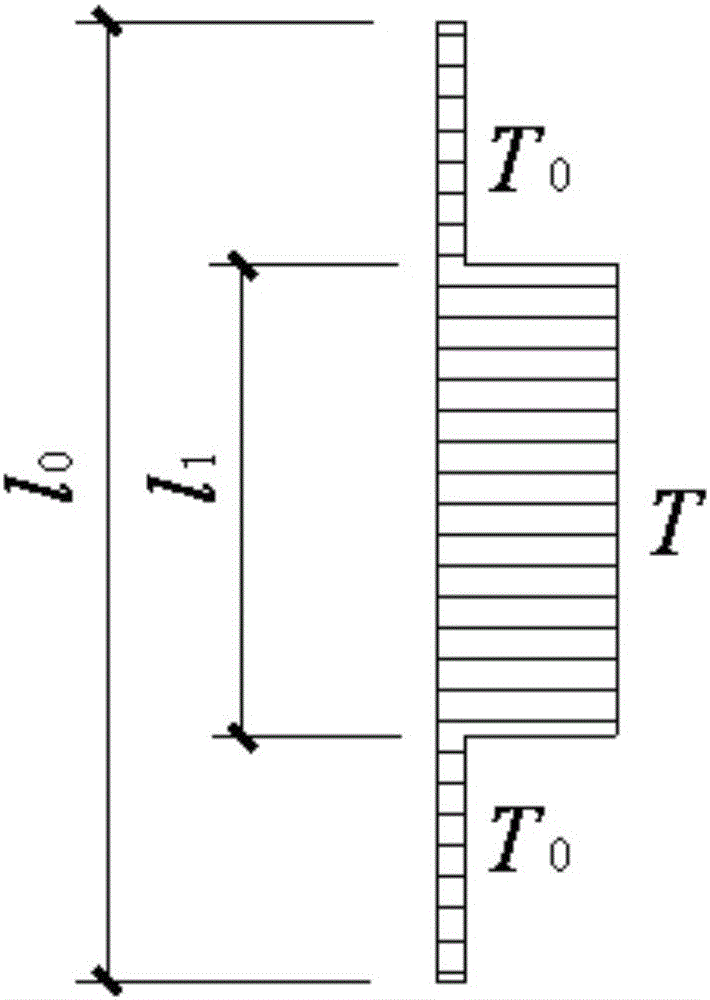

[0039] Rebar strain less than ε 0 When the loading rate is v 1 ; The steel bar strain test system simultaneously measures the stress, strain, stress, and displacement of steel bars at high temperatures;

[0040] When the steel strain exceeds ε 0 When the high-temperature strain extensometer in the steel bar strain test system reaches the measuring range, the steel bar strain test system automatically switches to di...

specific Embodiment approach 2

[0061] Embodiment 2: This embodiment is different from Embodiment 1 in that: the high temperature in the step 1 is 20-1100°C. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0062] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the high temperature in the step 1 is 50-1000°C. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com