Imaging system for patterning of an image definition material by electro-wetting and methods therefor

An image-defining technology, applied to the equipment of the electric recording process using the charge pattern, the electric recording process using the charge pattern, the electric recording process using the charge pattern, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] We initially point out that descriptions of well-known starting materials, processing techniques, components, devices, and other well-known details are only generalized or are omitted so as not to unnecessarily obscure the present disclosure. Therefore, where details are otherwise known, we leave it to the application of this disclosure to suggest or dictate choices concerning those details.

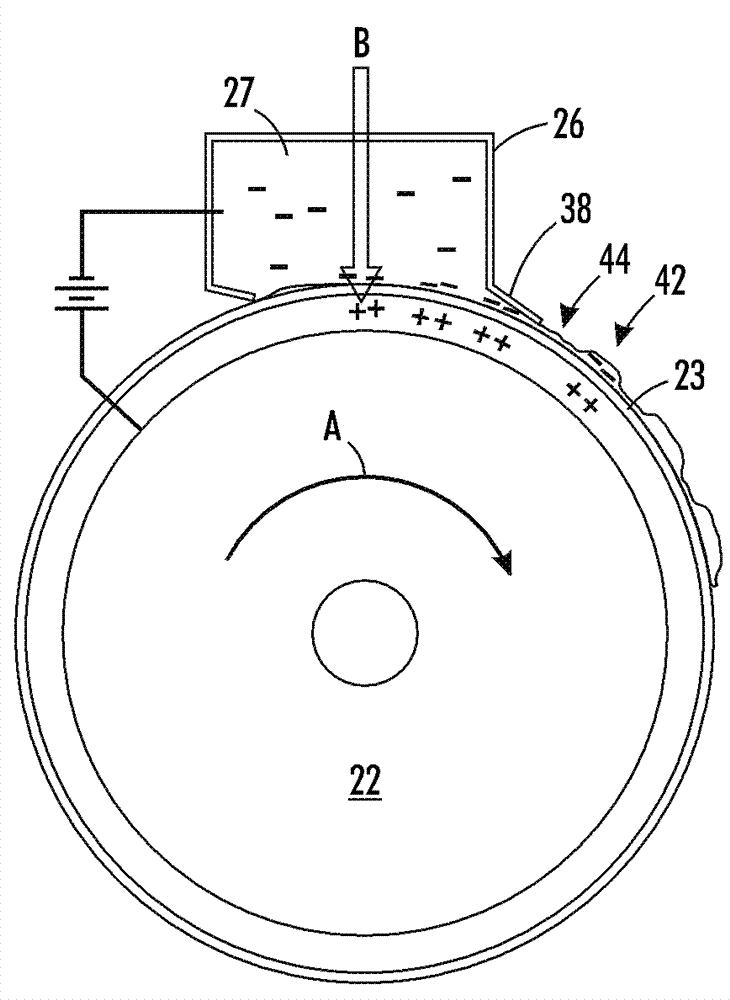

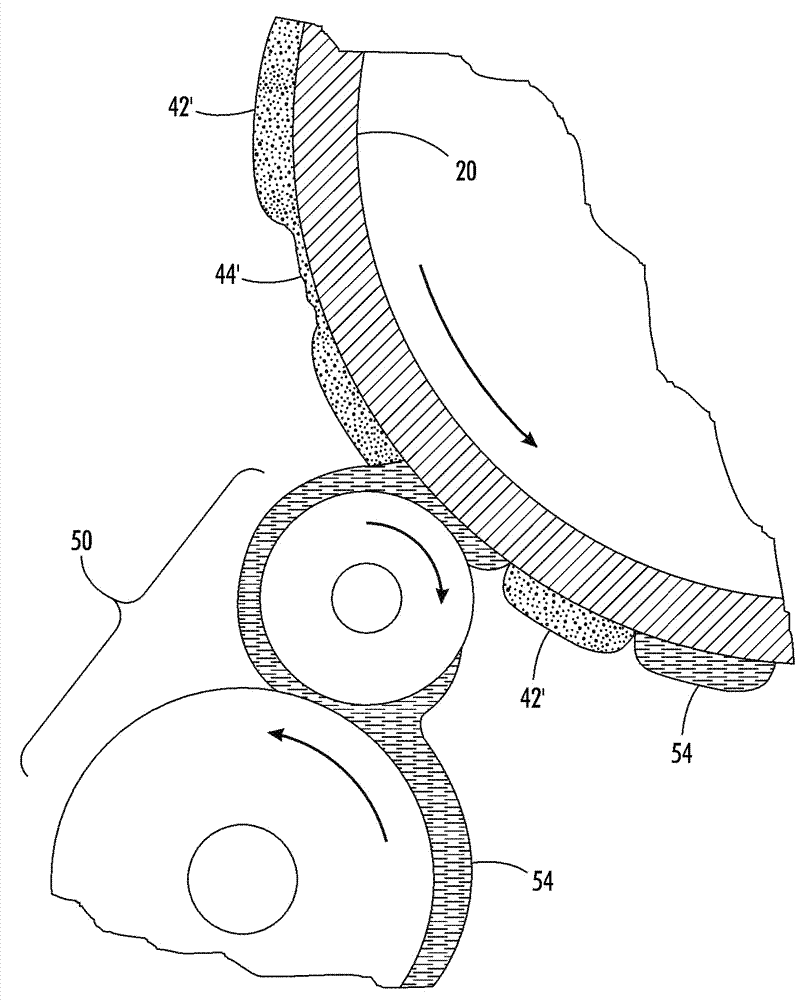

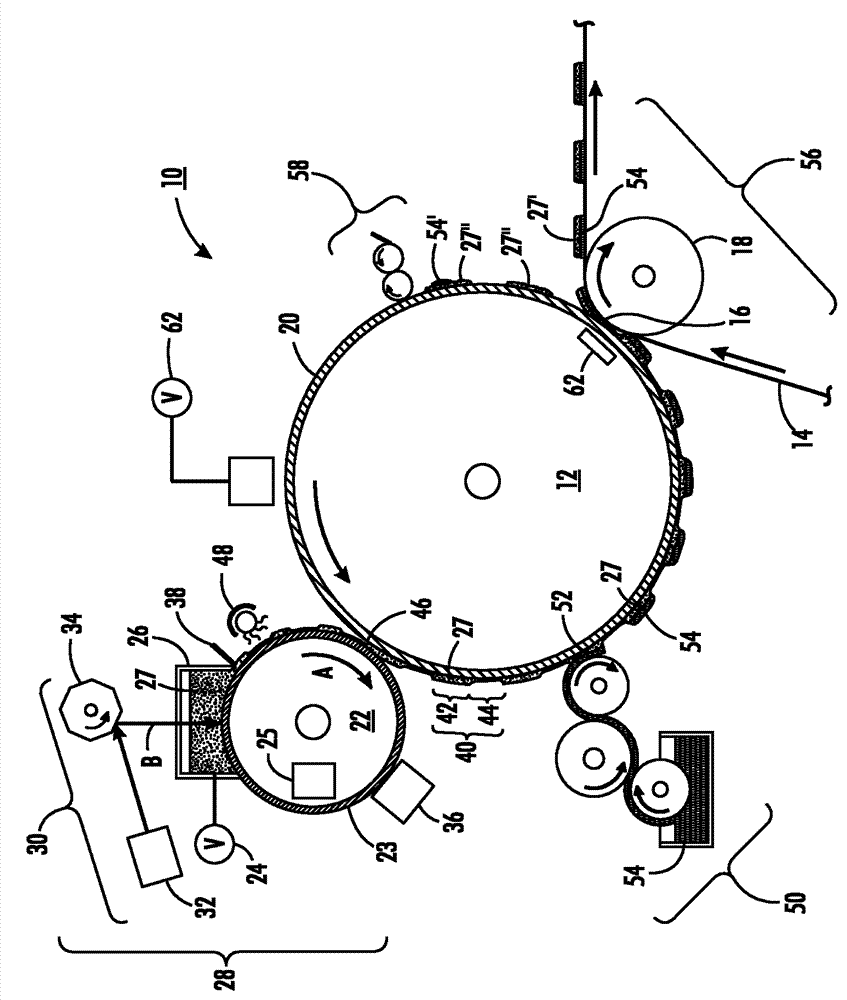

[0034] refer to figure 1 , in which is shown a system 10 for electrophotographic patterning of image definition materials according to one implementation of the present disclosure. System 10 includes an imaging component 12, in this implementation a drum, but could equally be a plate, belt, etc., surrounded by several subsystems described in detail below. Imaging member 12 applies an ink image to substrate 14 at nip 16 where substrate 14 is sandwiched between imaging member 12 and pressure roller 18 . A wide variety of substrate types can be used, such as paper, plastic or synth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com