Track reversing device of cable drum carriage

A technology of reversing device and pay-off car, which is applied to cable laying equipment and other directions, can solve the problems of a lot of wasted space, large safety hazards, and large area occupied by the track, so as to achieve small occupied space, high safety, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

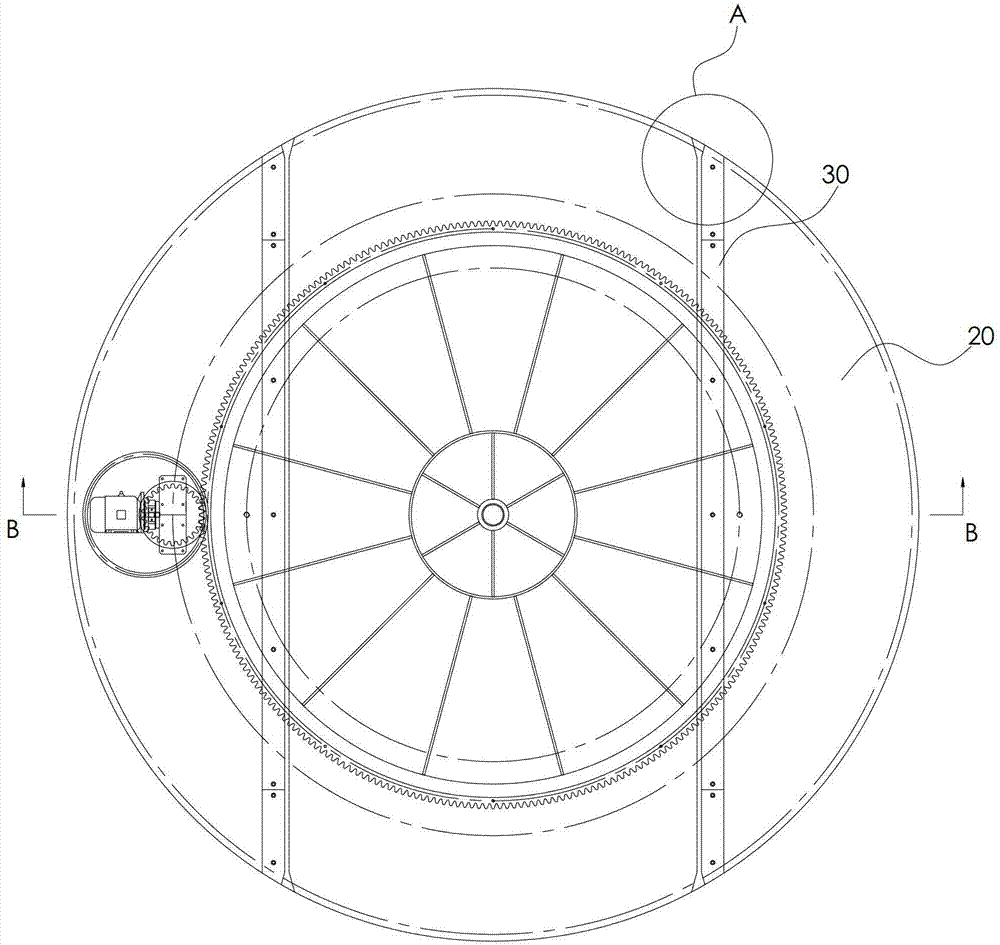

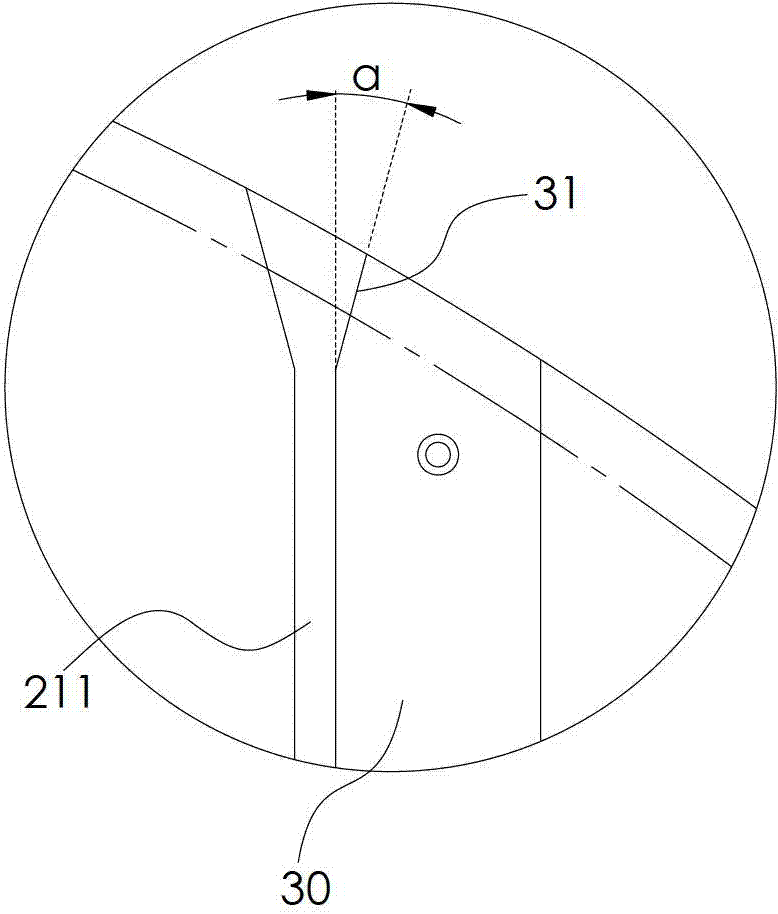

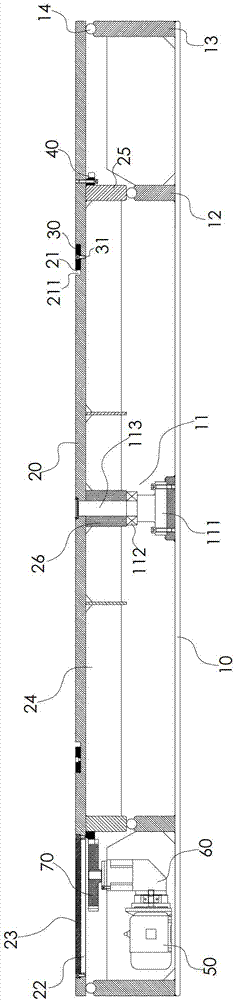

[0030] Such as figure 1 , 2 , shown in 3, is the track reversing device of the cable pay-off car of the present invention, and it comprises base plate 10, rotating disk 20, two track plates 30 and motor 50, and wherein, base plate 10 is as the basic part of whole device, and its base plate 10 The upper surface of the middle part is provided with a rotating shaft assembly 11 whose rotation axis is perpendicular to the bottom plate 10; the turntable 20 is located above the bottom plate 10 and is parallel to the bottom plate 10, and the middle part of the turntable 20 is pivotally connected above the bottom plate 10 through the rotating shaft assembly 11, specifically Yes, the rotating shaft assembly 11 includes a mounting base 111 fixedly mounted on the upper surface of the bottom plate 10, a pivot 113 pivotally connected to the mounting base 111 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com