A Laser Prestressed Forming Fixture with Loading and Springback Measurement

A prestressing and fixture technology, which is applied in the direction of manufacturing tools, metal processing equipment, feeding devices, etc., can solve the problems that the clamping fixture cannot achieve the expected results, the clamping plate does not have versatility, etc., and achieve high adjustability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

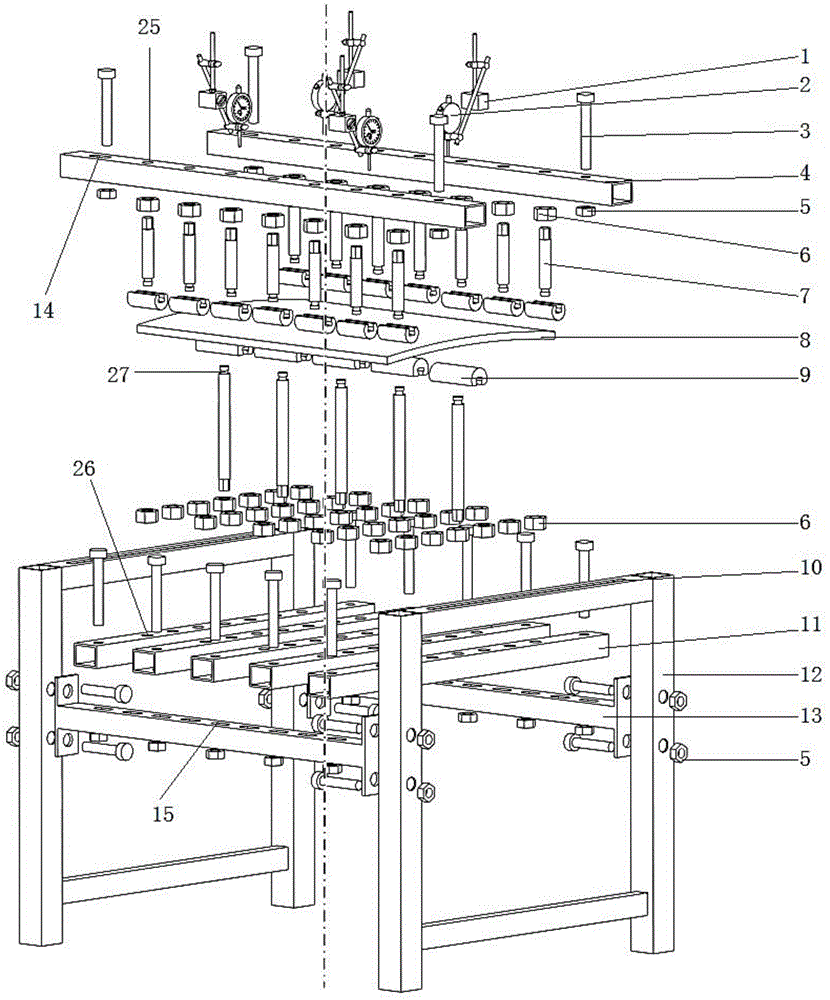

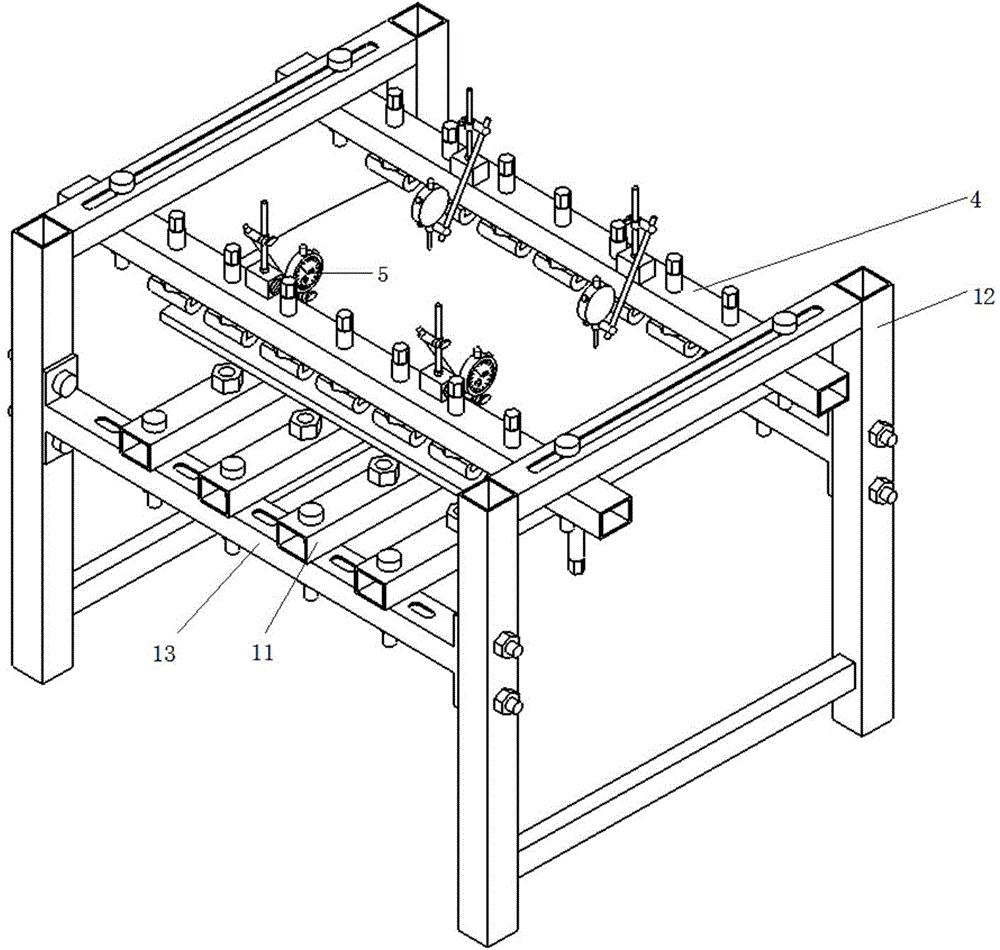

[0028] A laser prestressed forming fixture with loading and springback measurement in the present invention is mainly composed of six parts: rigid frame 12, upper beam 4, lower beam 13, connecting beam 11, dial indicator 2 and screw press block assembly, as follows Mainly introduce the composition and connection method of each component.

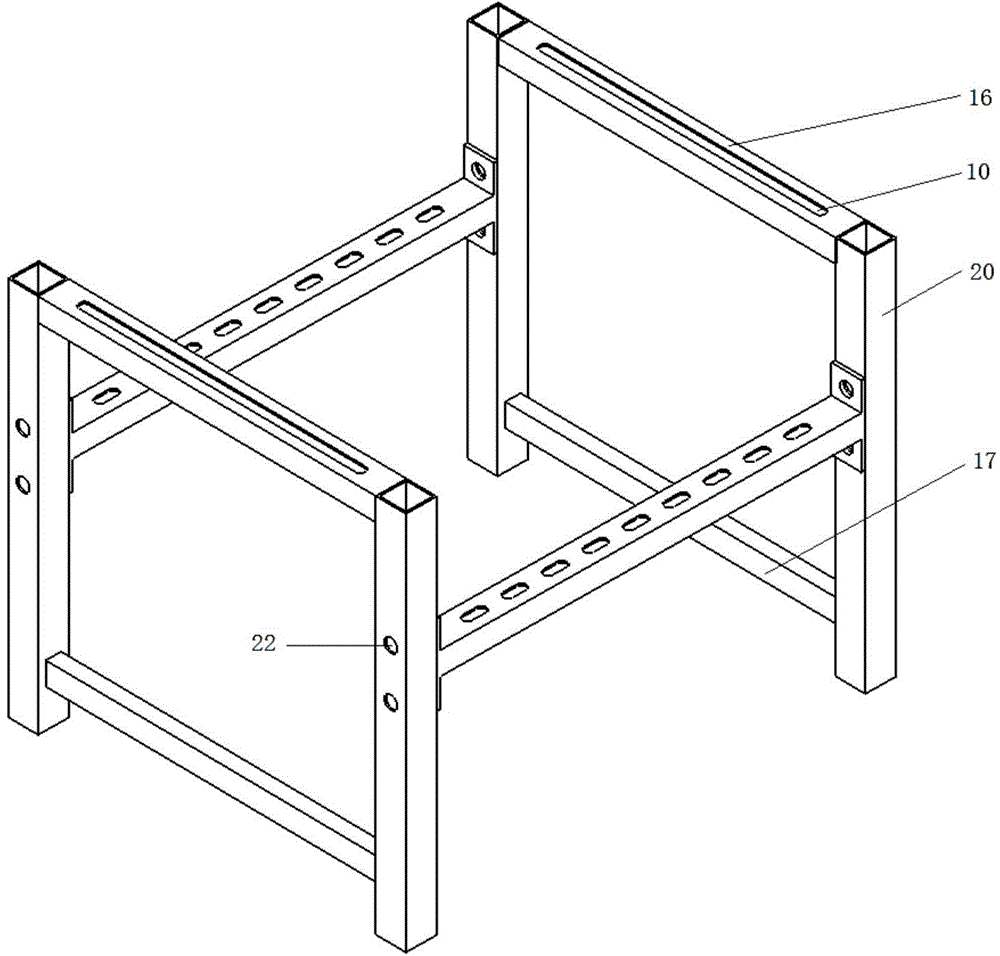

[0029] The rigid frame 12 is formed by welding two uprights 20 , an upper link 16 and a lower link 17 . A slide rail 10 is provided on the upper link 16 for fixing the upper beam 4, and the lower link 17 plays the role of strengthening the stability of the rigid frame 12. The two mutually symmetrically arranged rigid frames 12 are connected and fixed by bolts 3 and nuts 5 through the connecting holes 21 on the metal plates at both ends of the two lower beams 13 and the connecting holes 22 on the corresponding uprights 20 .

[0030] The upper crossbeam 4 is processed by a section of square steel. One end is provided with a first round hole 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com