Double nozzle ink stack alignment adjustment device

A technology of adjustment device and double nozzles, applied in printing and other directions, can solve the problems of poor product quality and temperature, and it is difficult for users to learn, and achieve the effect of avoiding jumping action, and the adjustment process is uniform and stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

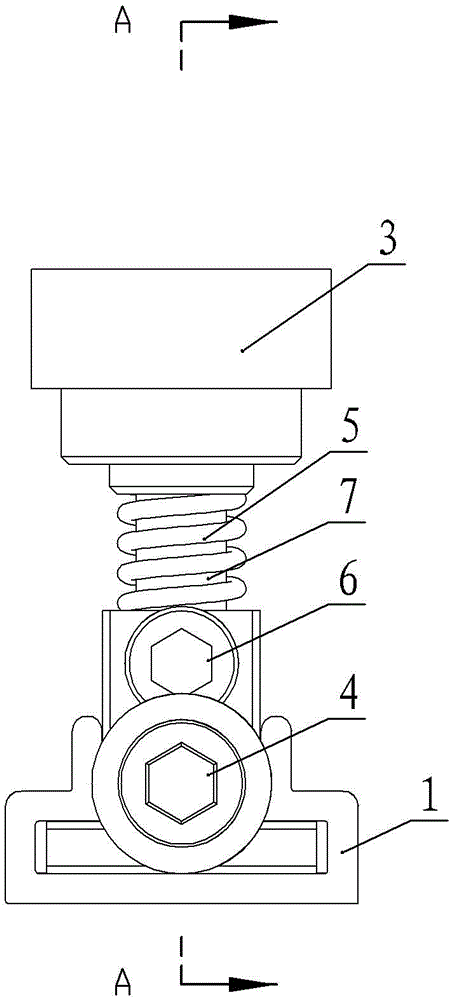

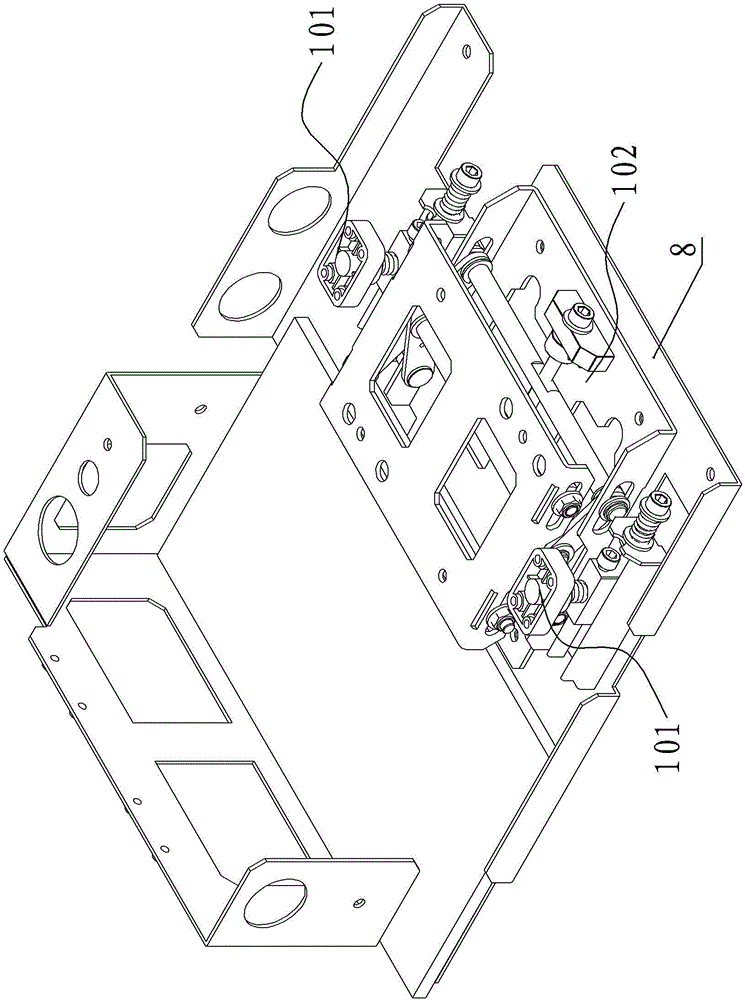

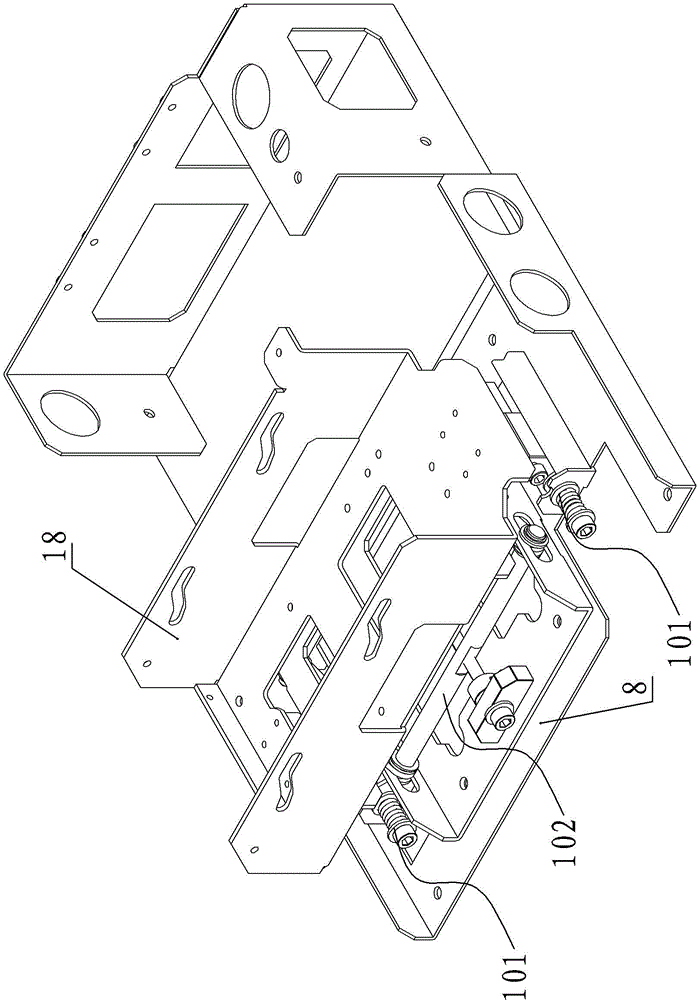

[0027] Example: see Figure 1-12 In the figure, a dual-nozzle ink stack alignment adjustment device includes an ink stack shell and a base, and is connected to the base through a lifting mechanism and a horizontal adjustment mechanism at the lower part of the ink stack shell, and its features are:

[0028] The lifting mechanism includes two lifting frames hinged in an "X" shape, an upper shelf connected to the ink stack housing, and a lower shelf connected to the base,

[0029] The two upper ends, lower ends, and middle hinge points of the two lifting frames are all connected by horizontal shafts to connect the two lifting frames into one body, and the two ends of the two horizontal axes A connecting the upper ends of the two lifting frames are supported on In the horizontal oblong hole A of the vertical plate of the upper shelf, the horizontal axis B that connects one pair of lower ends of the two lifting frames is hinged in the support hole of the vertical plate of the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com