Preparation method of biomimetic gecko composite microarray

A technology of microarray and gecko, which is applied in the field of bionic gecko composite microarray preparation, can solve the problems of high cost, complicated operation, and difficult demoulding, and achieve the effect of low cost, simple operation, and controllable experimental parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

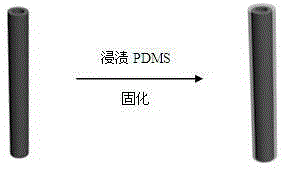

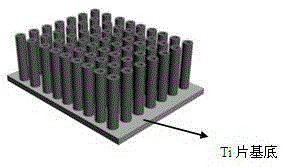

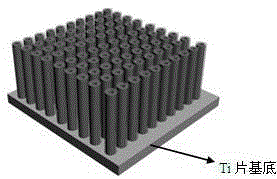

[0020] Specific implementation mode one: as figure 1 As shown, this embodiment prepares TiO according to the following steps 2 Nanotube / PDMS composite microarray:

[0021] Step 1: Preparation of TiO by anodic oxidation 2 nanotube microarray;

[0022] Ti sheet (1-8cm 2 ) for physical polishing, chemical polishing (30%HF and 25%HNO 3 aqueous solution), absolute ethanol and distilled water for repeated ultrasonic cleaning, and dry at room temperature for later use. Prepare a 0.1-5wt% HF aqueous solution, use the dried metal sheet as the anode, and the platinum sheet as the cathode. The distance between the two electrodes is 2-5cm. Perform anodic oxidation in a plexiglass electrolytic cell. The test is at room temperature (20°C). conduct. The voltage range is 10-60V, and the oxidation time is 2min-25h. Take out the oxidized Ti, wash it repeatedly with water, and dry it to get one-dimensional TiO 2 array of nanotubes.

[0023] The second step, preparation of TiO by impregn...

specific Embodiment approach 2

[0025] Specific embodiment two: this embodiment prepares imitation gecko foot microarray according to the following steps:

[0026] Step 1: Preparation of TiO by anodic oxidation 2 nanotube microarray;

[0027] Ti sheet (4cm 2 ) for physical polishing, chemical polishing (30%HF and 25%HNO 3 aqueous solution), anhydrous ethanol and distilled water for repeated ultrasonic cleaning, and dried at room temperature for use, prepared with 0.5wt% HF aqueous solution. The dried metal sheet was used as the anode, the platinum sheet was used as the cathode, and the distance between the two electrodes was 2 cm. Anodic oxidation was carried out in a plexiglass electrolytic cell, and the test was carried out at room temperature (20°C). The voltage is 18V, and the oxidation time is 5min. Take out the oxidized Ti, wash it repeatedly with water, and dry it to get one-dimensional TiO 2 array of nanotubes.

[0028] The second step, preparation of TiO by impregnation method 2 Nanotube / PDMS...

specific Embodiment approach 3

[0031] Specific embodiment three: this embodiment prepares imitation gecko foot microarray according to the following steps:

[0032] Step 1: Preparation of TiO by anodic oxidation 2 nanotube microarray;

[0033] Ti sheet (4cm 2 ) for physical polishing, chemical polishing (30%HF and 25%HNO 3 aqueous solution), anhydrous ethanol and distilled water for repeated ultrasonic cleaning, and dried at room temperature for later use, prepared with 0.5wt% NH 4Glycerol solution of F. The dried metal sheet was used as the anode, the platinum sheet was used as the cathode, and the distance between the two electrodes was 4cm. The anodic oxidation was carried out in a plexiglass electrolytic cell, and the test was carried out at room temperature (20°C). The voltage is 60V, and the oxidation time is 20h. Take out the oxidized Ti, wash it repeatedly with water, and dry it to get one-dimensional TiO 2 array of nanotubes.

[0034] The second step, preparation of TiO by impregnation metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com