A flame-retardant heat-insulating asphalt concrete and its preparation method

An asphalt concrete and asphalt technology, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem of less research on pavement materials and technologies in tunnels, and poor improvement in the flame retardant performance of asphalt concrete. , mass casualties and property losses, etc., to achieve the effect of reducing hydrophilicity, low price and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

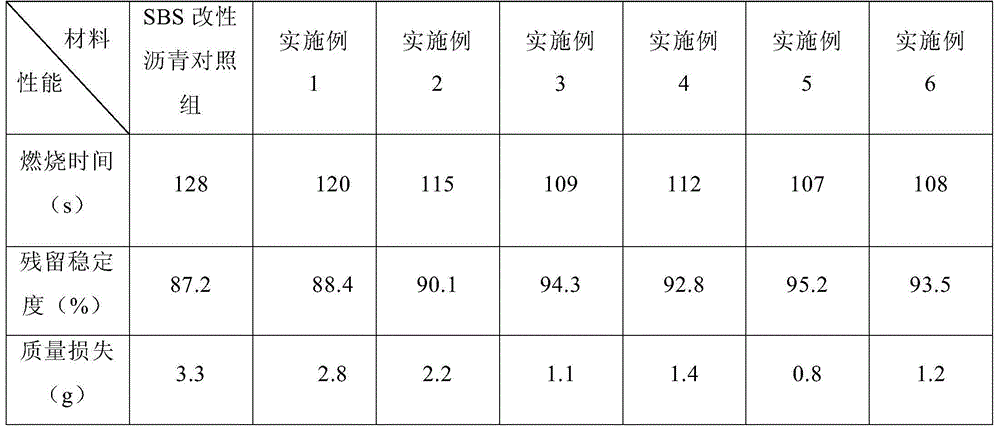

Examples

Embodiment 1

[0025] The environment-friendly flame-retardant asphalt in this embodiment is made of the following raw materials in mass percentage: mineral aggregate 94.8%, asphalt 5.04%, rectorite 0.15%, coupling agent 0.01%; the sum of raw material mass percentage is 100%; the coupling The agent solution is prepared by mixing the silane coupling agent and the solvent at a mass ratio of 1:3, and the solvent is ethanol.

[0026] Said parts by weight can be weight measurement units such as gram, liang, jin, kilogram, ton.

[0027] The preparation method of the environment-friendly flame-retardant asphalt of the present embodiment comprises the following steps:

[0028] Step 1, drying, pulverizing and sieving rectorite to obtain rectorite powder;

[0029] Step 2, adding the crushed and sieved rectorite powder into the coupling agent solution to stir, and then placing it in a drying oven to dry the rectorite powder;

[0030] Step 3: Heat the asphalt to 140°C and add it to the mineral materia...

Embodiment 2

[0032] The environment-friendly flame-retardant asphalt of this embodiment is made of the following raw materials in parts by weight: 94.2% of ore material, 4.27% of asphalt, 1.51% of rectorite, and 0.02% of coupling agent; the coupling agent solution is composed of silane coupling agent and solvent It is prepared by mixing at a mass ratio of 1:4, and the solvent is ethanol. Said parts by weight can be weight measurement units such as gram, liang, jin, kilogram, ton.

[0033] The preparation method of the environment-friendly flame-retardant asphalt of the present embodiment comprises the following steps:

[0034] Step 1, drying, pulverizing and sieving rectorite to obtain rectorite powder;

[0035] Step 2, adding the crushed and sieved rectorite powder into the coupling agent solution to stir, and then placing it in a drying oven to dry the rectorite powder;

[0036] Step 3: After heating the asphalt to 150°C, add it to the mineral material at 190°C and mix for 90 seconds, ...

Embodiment 3

[0038] The environment-friendly flame-retardant asphalt of this embodiment is made of the following raw materials in parts by weight: mineral aggregate 92.3%, asphalt 5.26%, rectorite 2.4%, coupling agent 0.04%; the coupling agent solution is composed of silane coupling agent and solvent It is made by mixing at a mass ratio of 1:5, and the solvent is ethanol.

[0039] The parts by mass can be weight measurement units such as gram, liang, jin, kilogram, ton.

[0040] The preparation method of the environment-friendly flame-retardant asphalt of the present embodiment comprises the following steps:

[0041] Step 1, drying, pulverizing and sieving rectorite to obtain rectorite powder;

[0042] Step 2, adding the crushed and sieved rectorite powder into the coupling agent solution to stir, and then placing it in a drying oven to dry the rectorite powder;

[0043] Step 3: Heat the asphalt to 160°C and add it to the mineral material at 200°C and mix for 90 seconds, then add rectori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com