Environment-friendly flame-retardant asphalt and preparation method thereof

An asphalt and environmental protection technology, which is applied in building insulation materials, building components, buildings, etc., can solve the problems of poor flame retardant effect, large smoke, and toxicity of decomposition products of inorganic flame retardants alone, and achieves the reduction of hydrophilicity and simple preparation , strong adsorption and exchange effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

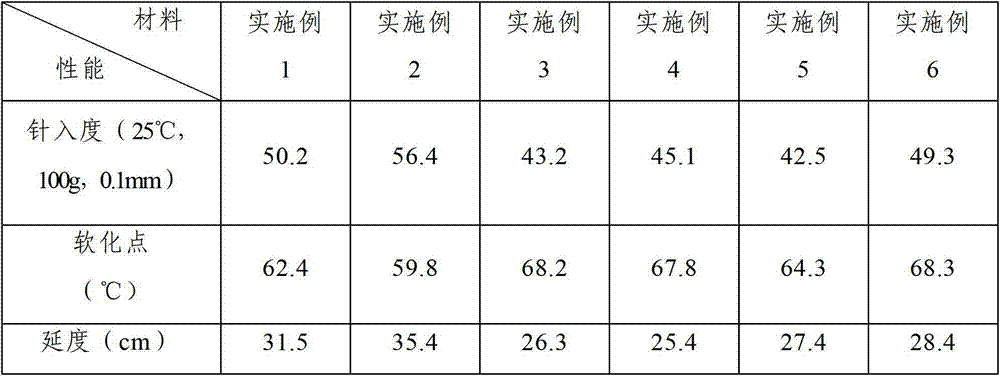

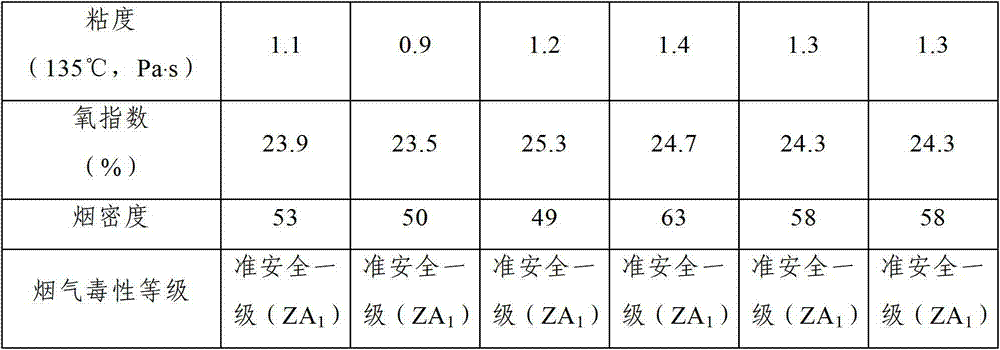

Examples

Embodiment 1

[0022] The environment-friendly flame retardant asphalt of this embodiment is made of the following raw materials in parts by weight: 100 parts of asphalt, 6 parts of medical stone, 15 parts of metal hydroxide, 4 parts of smoke suppressant, and 10 parts of coupling agent solution; the asphalt is Road petroleum asphalt; the metal hydroxide is aluminum hydroxide, the smoke suppressant is calcium oxide, and the coupling agent solution is made by mixing a titanate coupling agent and a solvent in a mass ratio of 1:4. Described solvent is methyl alcohol; Described parts by weight can be weight measurement units such as gram, two, jin, kilogram, ton, described road petroleum asphalt can adopt the road petroleum asphalt produced by Shandong Yurun Road Material Co., Ltd., described titanate As the coupling agent, titanate coupling agent produced by Tianchang Green Chemical Auxiliary Factory can be used.

[0023] The preparation method of the environment-friendly flame-retardant asphalt...

Embodiment 2

[0029] The environment-friendly flame retardant asphalt in this embodiment is made from the following raw materials in parts by weight: 100 parts of asphalt, 5 parts of medical stone, 10 parts of metal hydroxide, 3 parts of smoke suppressant, and 5 parts of coupling agent solution; the asphalt is Road petroleum asphalt; the metal hydroxide is magnesium hydroxide, the smoke suppressant is calcium oxide, and the coupling agent solution is made by mixing a titanate coupling agent and a solvent in a mass ratio of 1:5. Described solvent is ethanol; Described parts by weight can be weight measurement units such as gram, two, jin, kilogram, ton; Described road petroleum asphalt can adopt the road petroleum asphalt produced by Hengshui Diyi Petrochemical Co., Ltd., and described titanate The coupling agent can be a titanate coupling agent produced by Nanjing Pinning Coupling Agent Co., Ltd.

[0030] The preparation method of the environment-friendly flame-retardant asphalt of the pres...

Embodiment 3

[0036] The environment-friendly flame retardant asphalt in this embodiment is made from the following raw materials in parts by weight: 100 parts of asphalt, 3 parts of medical stone, 12 parts of metal hydroxide, 5 parts of smoke suppressant, and 12 parts of coupling agent solution; the asphalt is SBS modified asphalt; the metal hydroxide is magnesium hydroxide, the smoke suppressant is calcium oxide, and the coupling agent solution is made by mixing a titanate coupling agent and a solvent in a mass ratio of 1:5, The solvent is deionized water; the parts by weight can be weight units such as gram, two, kilogram, kilogram, ton; the SBS modified asphalt can be the SBS modified asphalt produced by Shanghai Qunkang Asphalt Technology Co., Ltd. The titanate coupling agent can be the titanate coupling agent produced by Tianchang Green Chemical Auxiliary Factory.

[0037] The preparation method of the environment-friendly flame-retardant asphalt of the present embodiment comprises th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com