Multifunctional environment-friendly modified asphalt and preparation method thereof

A modified asphalt, multi-functional technology, applied in the direction of building insulation materials, building components, climate change adaptation, etc., can solve the problems of imperfect performance, high thermal mixing, single environmental effect, etc., to achieve excellent road performance and reduce heat island effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

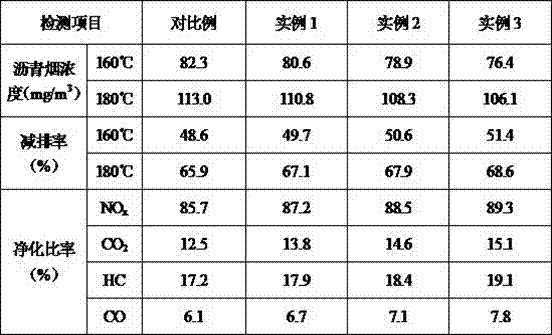

Examples

example 1

[0021] Weigh 10g of zinc chloride, add 300mL of sodium bicarbonate solution with a mass fraction of 10%, stir at 300r / min for 15min, then heat with 300W microwave for 20min, cool to room temperature and filter to obtain a filter residue, then use absolute ethanol and deionized Wash the filter residue with water for 3 times, then place it in a muffle furnace, and calcinate it at 550°C for 1 hour to obtain nano-active zinc oxide. Weigh 200g of waste rubber powder, put it into a pulverizer and pulverize it, pass through a 200-mesh sieve, and sieve Put the final rubber powder into a beaker, then add 300mL of toluene, 300mL of xylene, 30mL of glacial acetic acid, 20mL of anhydrous formic acid, 10g of zinc chloride, 10g of ferric chloride, and 2mL of 98% sulfuric acid solution with a mass fraction of React for 5 hours, then filter with suction, place the filter cake in a drying oven at 105°C and dry to constant weight to obtain desulfurized rubber powder, weigh 20g of tourmaline, put...

example 2

[0023] Weigh 11g of zinc chloride, add it to 400mL of 10% sodium bicarbonate solution, stir at 350r / min for 18min, then heat with 300W microwave for 25min, cool to room temperature and filter to obtain a filter residue, then use absolute ethanol and deionized Wash the filter residue with water for 4 times, then place it in a muffle furnace, and calcinate it at 575°C for 1 hour to obtain nano-active zinc oxide. Weigh 250g of waste rubber powder, add it to a pulverizer, and pass it through a 200-mesh sieve. Put the final rubber powder into a beaker, then add 350mL toluene, 350mL xylene, 40mL glacial acetic acid, 25mL anhydrous formic acid, 15g zinc chloride, 15g ferric chloride, 2mL mass fraction of 98% sulfuric acid solution, at 75°C React for 7 hours, then filter with suction, place the filter cake in a drying oven at 108°C and dry to constant weight to obtain desulfurized rubber powder. Weigh 25g of tourmaline, add it to a pulverizer, and pass it through a 325-mesh sieve. Sto...

example 3

[0025]Weigh 12g of zinc chloride, add it to 500mL of 10% sodium bicarbonate solution, stir at 400r / min for 20min, then heat with 300W microwave for 30min, cool to room temperature and filter to obtain a filter residue, then use absolute ethanol and deionized Wash the filter residue with water for 5 times, then place it in a muffle furnace, and calcinate it at 600°C for 2 hours to obtain nano-active zinc oxide. Weigh 300g of waste rubber powder, add it to a pulverizer, and pass it through a 200-mesh sieve. Put the final rubber powder into a beaker, then add 400mL toluene, 400mL xylene, 50mL glacial acetic acid, 30mL anhydrous formic acid, 20g zinc chloride, 20g ferric chloride, 3mL mass fraction of 98% sulfuric acid solution, at 80 °C React for 8 hours, then filter with suction, put the filter cake in a drying oven at 110°C and dry to constant weight to obtain desulfurized rubber powder, weigh 30g of tourmaline, put it into a pulverizer and grind it, pass through a 325 mesh siev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com