A kind of composite asphalt warm mixing viscosity reducer and preparation method thereof

A kind of viscosity reducer and composite technology, which can be used in building thermal insulation materials, building components, climate change adaptation and other directions, can solve problems such as environmental pollution and increase in polluting gas emissions, and achieve good high temperature performance overcoming environmental pollution, reducing emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

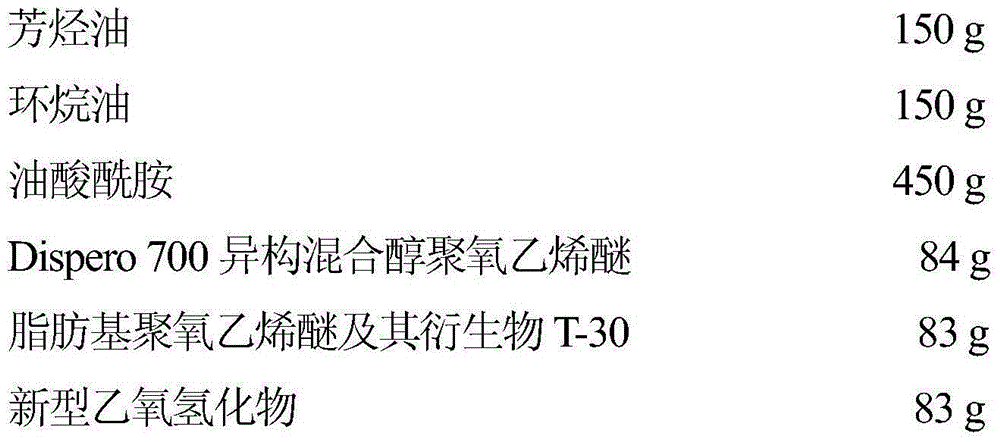

[0026] Taking the preparation of 1000g composite asphalt warm-mix viscosity reducer as an example, the raw materials used and their mass ratios are as follows:

[0027]

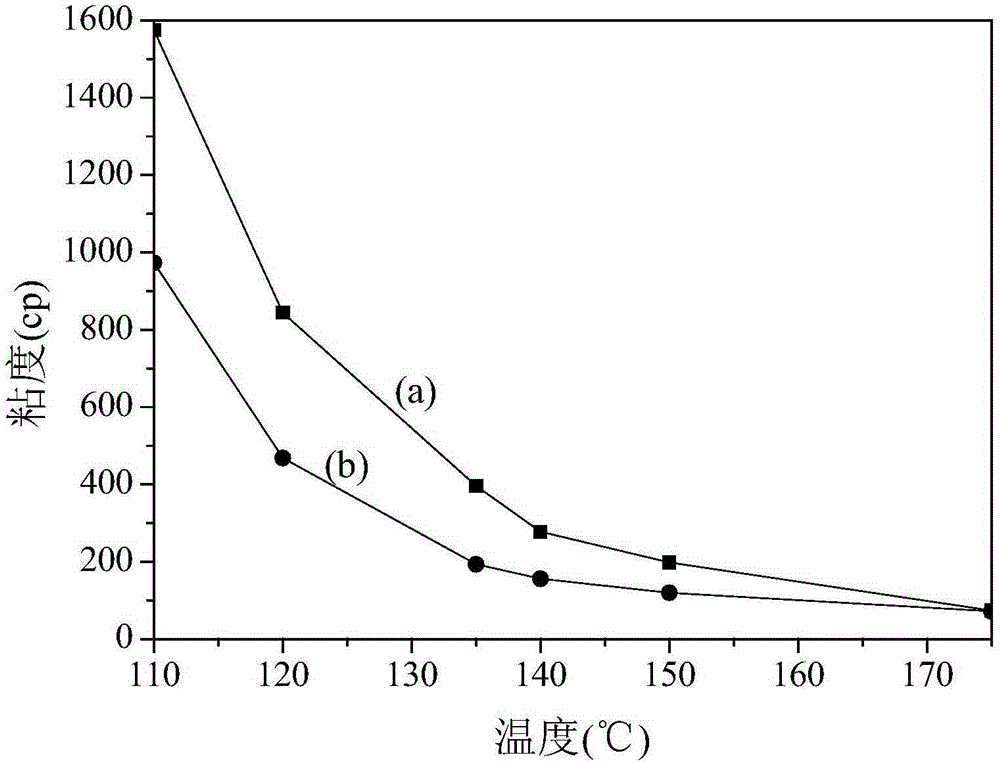

[0028] The preparation method of the above composite asphalt warm-mix viscosity reducer is as follows: 150g aromatic oil, 150g naphthenic oil, 84g Dispero700 isomerized mixed alcohol polyoxyethylene ether, 83g aliphatic polyoxyethylene ether and its derivative T-30, 83g Mix the new ethoxylated hydride, heat to 110-120°C, stir evenly, then add 450g of oleic acid amide, after it is completely melted, heat up to 130-140°C, and cut it with a high-speed shear for 10 minutes to obtain a compound type Warm mix viscosity reducer for asphalt.

Embodiment 2

[0030] Taking the preparation of 1000g composite asphalt warm-mix viscosity reducer as an example, the raw materials used and their mass ratios are as follows:

[0031]

[0032] Its preparation method is identical with embodiment 1.

Embodiment 3

[0034] Taking the preparation of 1000g composite asphalt warm-mix viscosity reducer as an example, the raw materials used and their mass ratios are as follows:

[0035]

[0036] Its preparation method is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com