Method for determining mixing amount of old material in recycled asphalt mixture

A technology for reclaiming asphalt and determining methods, applied in measurement devices, analytical materials, instruments, etc., can solve the problems of incomplete evaluation of the shear strength of asphalt mixtures, cumbersome methods for determining the dosage, and inability to simulate well. Save testing time, save time and energy, and achieve good road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

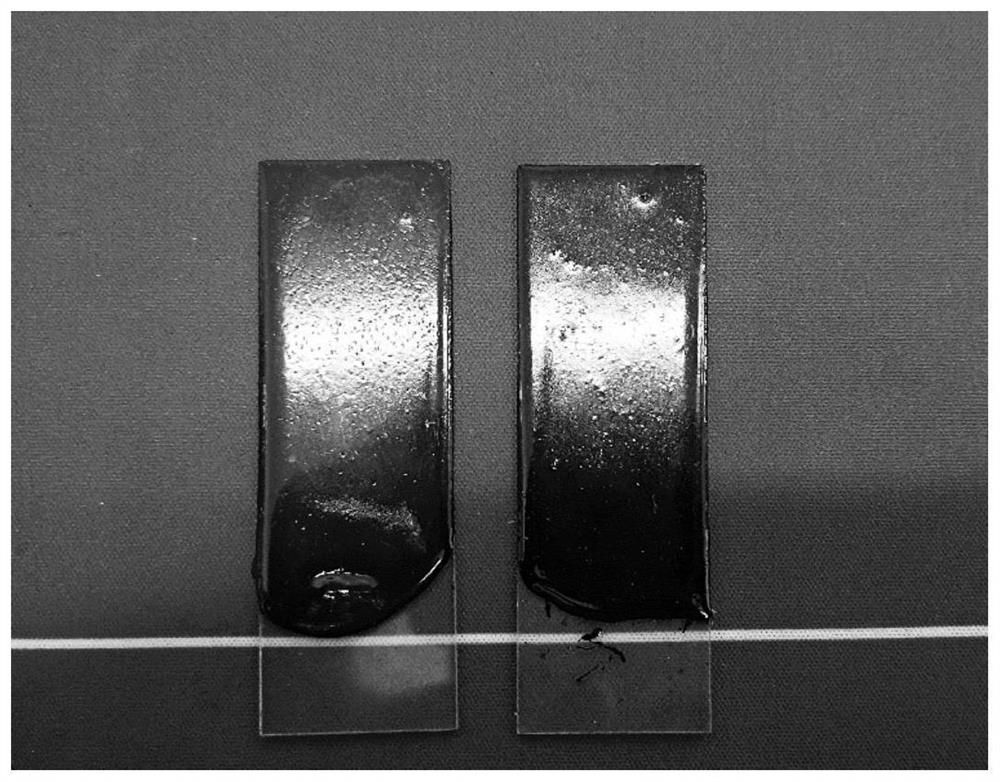

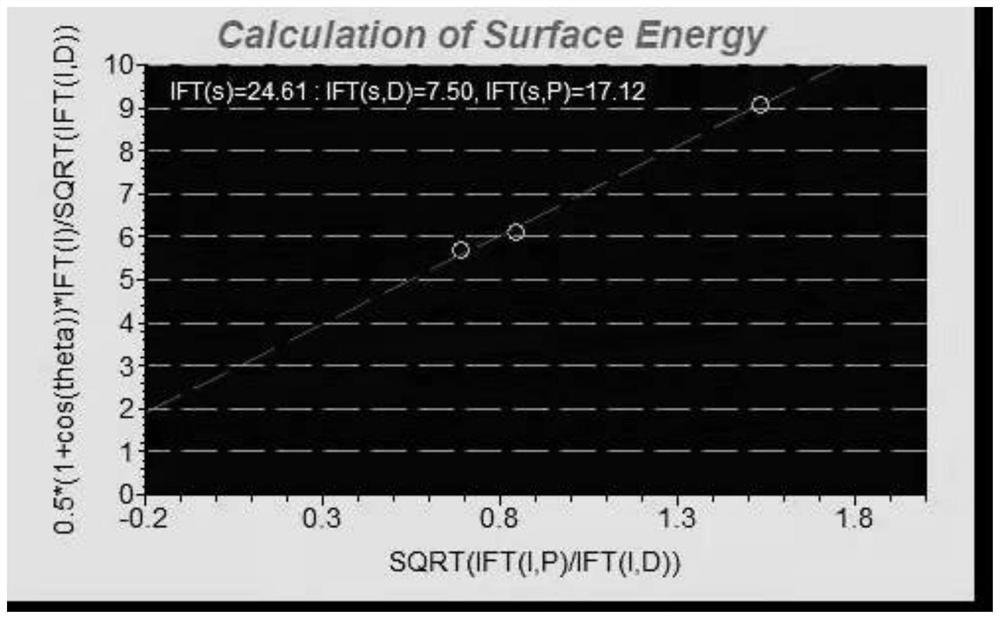

[0032] like figure 1 , 2 As shown in , 3, a method for determining the amount of old materials in recycled asphalt mixture, first obtain the surface energy of the new asphalt test specimen and the old asphalt test specimen, and then preset the surface energy of the required recycled asphalt, Finally, bring it into the calculation formula to get the amount of old materials in the required recycled asphalt. The specific steps are as follows:

[0033] (1) First clean the glass slide with distilled water to remove surface dust and other impurities, wipe the surface of the glass slide with absorbent cotton balls, and dry it close to a thermal electric furnace. Heat to 150°C, use a brush to dip a little drop onto the glass slide, slightly tilt the glass slide to make the asphalt flow slowly on the surface of the slide until it is smooth and free of bubbles, and the thickness of the asphalt on the prepared glass slide specimen is 1.5mm , put the finished new asphalt test specimen i...

Embodiment 2

[0045] A method for determining the amount of old materials in recycled asphalt mixtures. First obtain the surface energies of new asphalt test specimens and old asphalt test specimens, then preset the surface energy of the required recycled asphalt, and finally bring it into the calculation formula Get the amount of old material in the required recycled asphalt, the specific steps are as follows:

[0046] (1) First clean the glass slide with distilled water to remove surface dust and other impurities, wipe the surface of the glass slide with absorbent cotton balls, and dry it close to a thermal electric furnace. Heat to 150°C, use a brush to dip a little drop onto the glass slide, slightly tilt the glass slide to make the asphalt flow slowly on the surface of the slide until it is smooth and free of bubbles, and the thickness of the asphalt on the prepared glass slide specimen is 1.5mm , put the finished new asphalt test specimen into the dust-proof device and cover it until ...

Embodiment 3

[0056] A method for determining the amount of old materials in recycled asphalt mixtures. First obtain the surface energies of new asphalt test specimens and old asphalt test specimens, then preset the surface energy of the required recycled asphalt, and finally bring it into the calculation formula Get the amount of old material in the required recycled asphalt, the specific steps are as follows:

[0057] (1) First clean the glass slide with distilled water to remove surface dust and other impurities, wipe the surface of the glass slide with absorbent cotton balls, and dry it close to a thermal electric furnace. Heat to 150°C, use a brush to dip a little drop onto the glass slide, slightly tilt the glass slide to make the asphalt flow slowly on the surface of the slide until it is smooth and free of bubbles, and the thickness of the asphalt on the prepared glass slide specimen is 1.5mm , put the finished new asphalt test specimen into the dust-proof device and cover it until ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface energy | aaaaa | aaaaa |

| surface energy | aaaaa | aaaaa |

| surface energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com