Method for designing mix proportion of AC-25 recycled asphalt mixture

A technology of AC-25 and mix ratio design, which is applied in the field of road engineering and construction, can solve the problems of insufficient performance of asphalt products and imperfect consideration of design factors, so as to save asphalt cost, optimize gradation design, and have good road performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The asphalt used in this test is SBS modified asphalt provided by Jiangsu Zhongchuang Transportation Material Co., Ltd., and the SMC regenerant sample is provided by Shanxi Junyi Intelligent Transportation Technology Co., Ltd. The optimum modifier dosage in this test is 12% of the SBS modified asphalt. The process used in the indoor production of SMC and SBS composite modified asphalt is implemented according to the group standard of China Highway Society "Technical Guidelines for Construction of SMC Modified Asphalt Pavement" (T / CHTS 10007-2019).

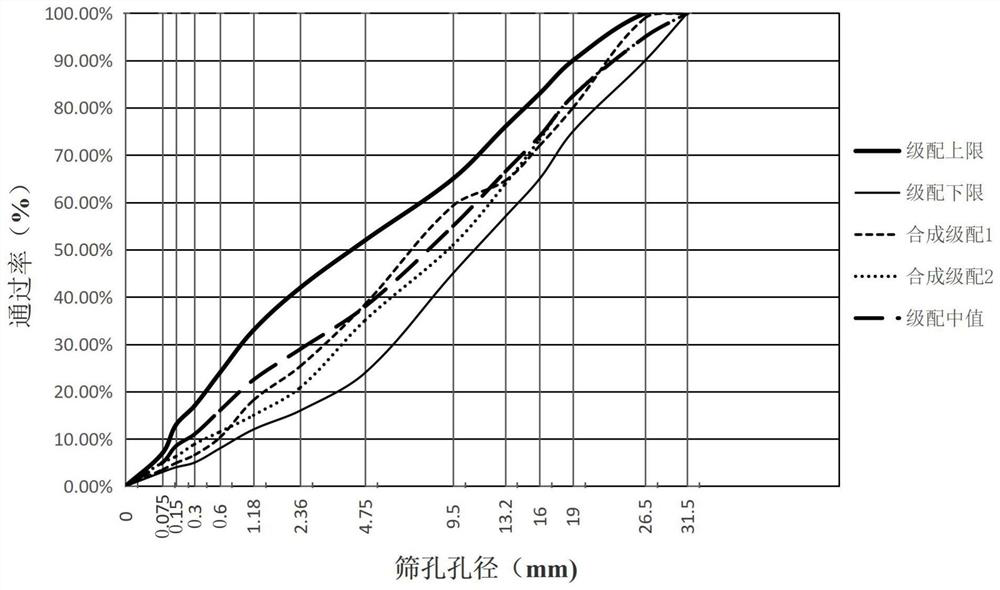

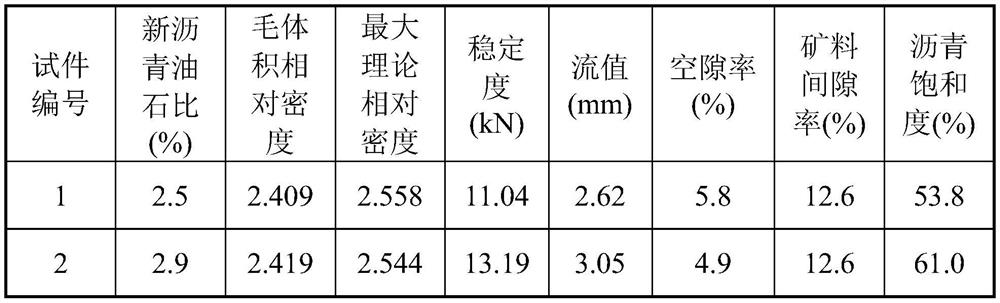

[0038] According to the gradation of the old materials and the pavement structure of the plant mixed heat regeneration structure layer as the lower layer, the selected mineral material gradation is AC-25C, the design gradation range requirements and the design gradation curve (synthetic gradation 1) See attached figure 1 . On the basis of ensuring the full use of the milling material as much as possible, a group of grades ...

Embodiment 2

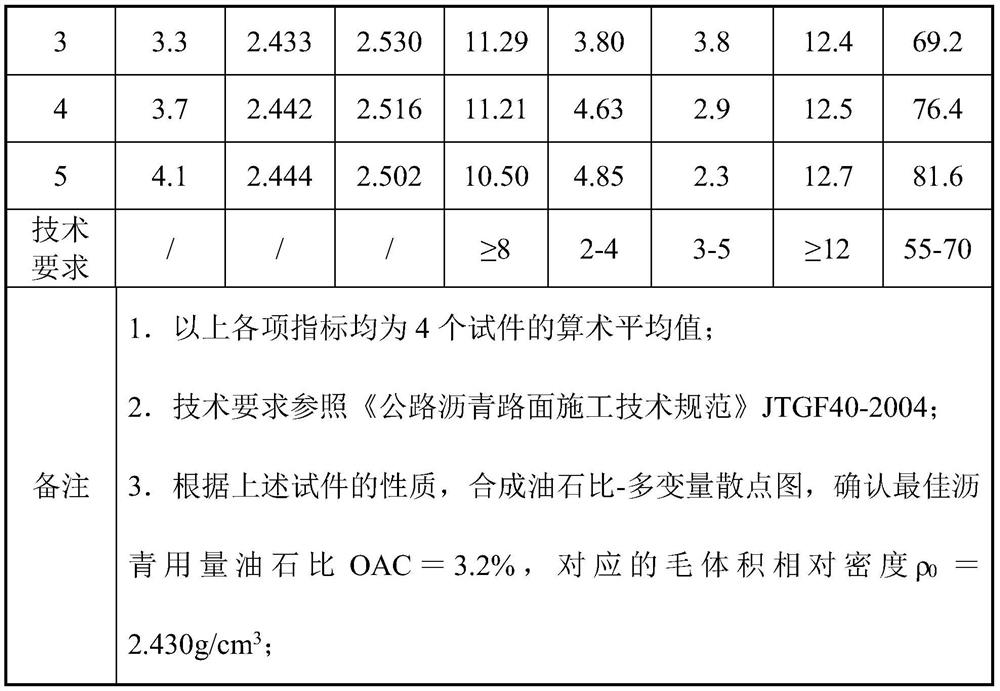

[0047] According to the gradation of old materials and the pavement structure of the plant mix heat regeneration structure layer as the lower layer, the selected mineral material gradation is AC-25C, the design gradation range requirements and the design gradation curve (synthetic gradation 2) See attached figure 1 . On the basis of ensuring the full use of the milling material as much as possible, a group of grades was selected for the test, and the RAP dosage was still 45%.

[0048] Under the condition of determined ore grading composition, based on engineering practice experience, five different asphalt-asphalt ratios of 1.4%, 1.8%, 2.2%, 2.6% and 3.0% are finally determined, and the asphalt mixture is determined by Marshall method. For comparison, Marshall test blocks were prepared by compacting 75 times on both sides. The recycled material is heated to 130°C, the virgin material is heated to 155°C, the asphalt heating temperature is 155°C, the mixing temperature of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap