Double-ventilation-element bottom blowing brick device

A technology of ventilating element and gas connecting device, which is applied to casting melt containers, manufacturing tools, metal processing equipment, etc., can solve the problems of unsatisfactory and unsatisfactory air permeability, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to further explain the technical means and effects adopted by the present invention to achieve the predetermined purpose, the specific implementation, system composition, features and effects of a double-ventilating element bottom brick blowing device proposed according to the present invention will be described below in conjunction with the accompanying drawings. Further explanation:

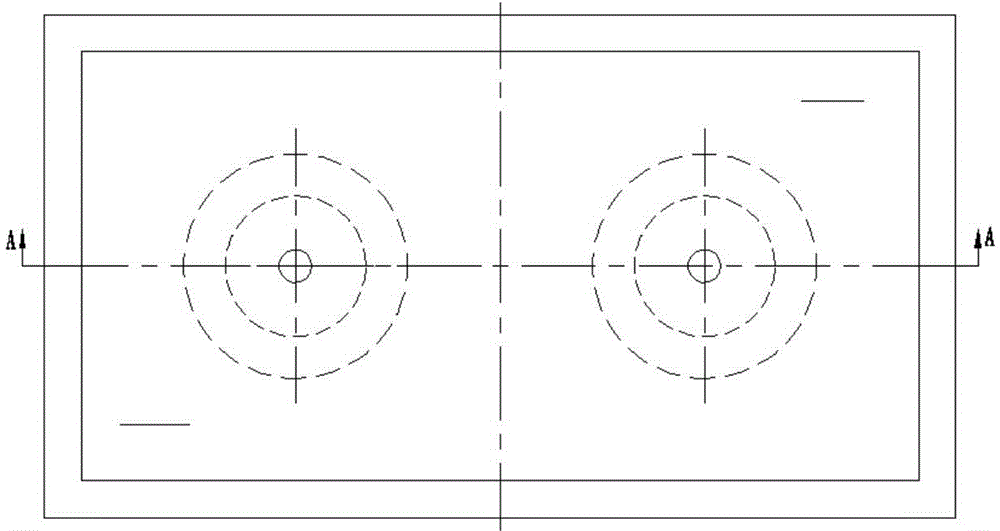

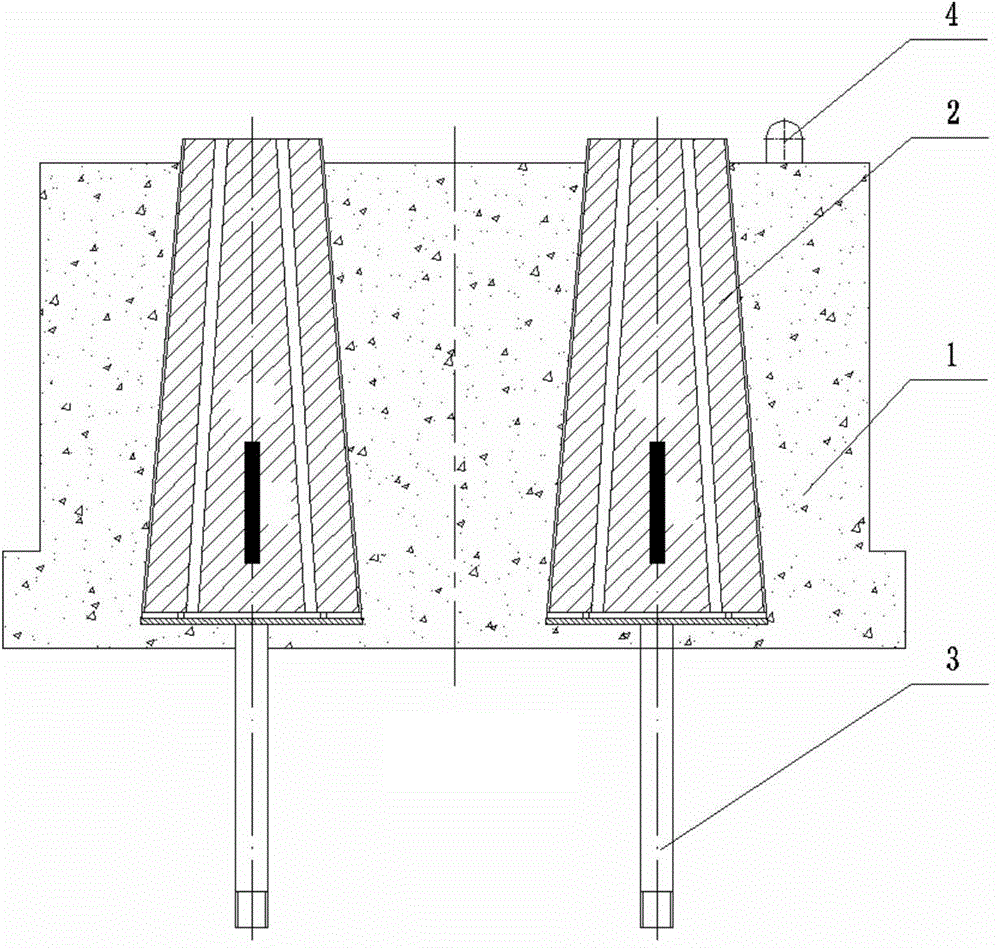

[0013] figure 1 — figure 2 It is a specific embodiment of the present invention.

[0014] Such as figure 1 As shown, the present invention includes an integral seat brick 1, a breathable core body 2, a gas connection device 3, and a lifting lug assembly 4; The gas pipeline on the container (commonly iron ladle, steel ladle, tundish, etc.) is connected; the lifting lug assembly 4 is connected with the integral seat brick 1, and is used for lifting by the bottom blowing brick device with double ventilation elements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com