An electroforming device

A kind of equipment and electroforming technology, which is applied in the field of electroforming replication of large-size metal casting plates, can solve the problems of difficult control of thickness uniformity, large space occupation of the site, and difficult actual operation, etc., to achieve small footprint and improve uniform thickness Sex, the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

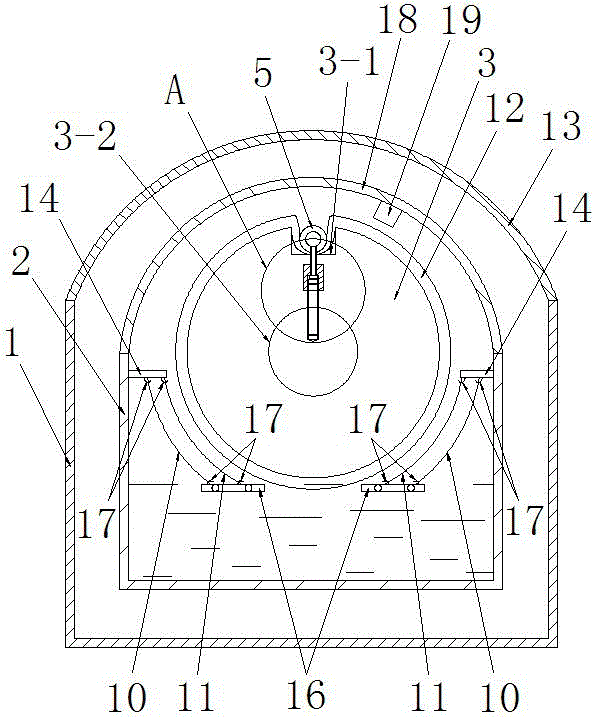

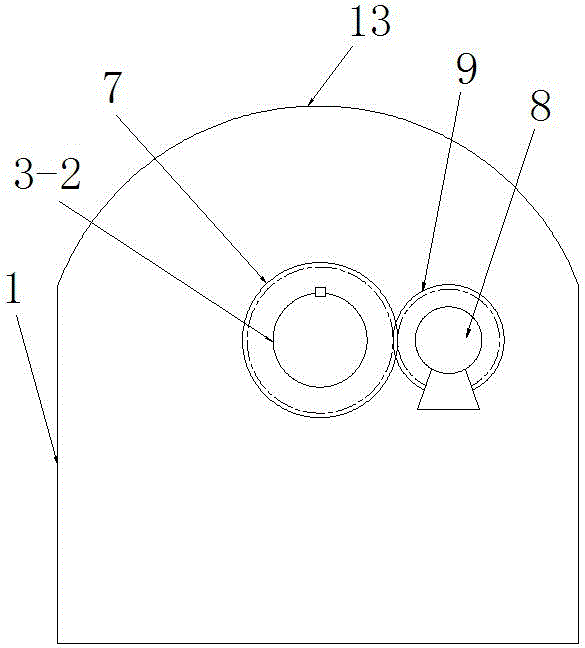

[0027] Embodiment 1: see attached figure 1 ~ attached Figure 7 , an electroforming equipment, including a collecting tank 1 and an electroforming tank 2 located in the collecting tank 1. The electroforming tank 2 uses a high-strength PP plate with a stainless steel skeleton inside to ensure the rigidity of the electroforming tank 2 and corrosion resistance.

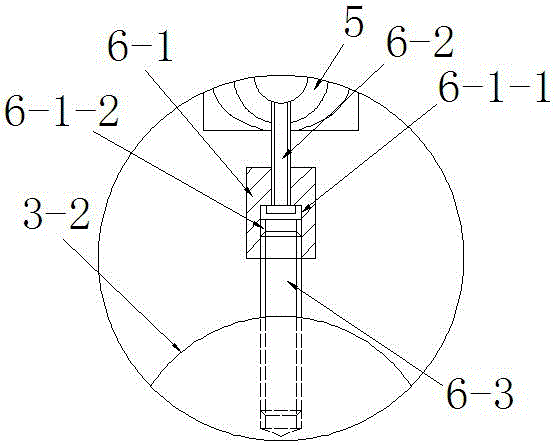

[0028] A cylinder 3 is horizontally fixed in the electroforming tank 2, and two metal titanium conductive rings 4 coaxial with the cylinder 3 and close to the circumferential surface of the cylinder 3 are fixed on the surface of the cylinder 3 in the axial direction. The thickness of example conductive ring 4 is 1mm, there is a groove 3-1 of 100mm * 100mm in the axial direction on the surface of cylinder 3, and a rubber pressure roller 5 with a diameter of 100mm is arranged in groove 3-1. There are short shafts 3-2 on both sides of the cylinder 3 along the axis, and the two ends of the pressure roller 5 are respectivel...

Embodiment 2

[0038] Embodiment 2: see attached figure 1 ~ attached Figure 6 , attached Figure 8 , an electroforming equipment, including a collecting tank 1 and an electroforming tank 2 located in the collecting tank 1. The electroforming tank 2 uses a high-strength PP plate with a stainless steel skeleton inside to ensure the rigidity of the electroforming tank 2 and corrosion resistance.

[0039] In this embodiment, there are triangular through grooves 11-2 along the arc surface of the cathode shielding baffle, and the rest of the structure and working process are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com